Optical fiber colored core wire

An optical fiber and core wire technology, applied in cladding optical fibers, multi-layer core/cladding optical fibers, etc., can solve the problem of not easy to identify the coloring core of optical fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be described first.

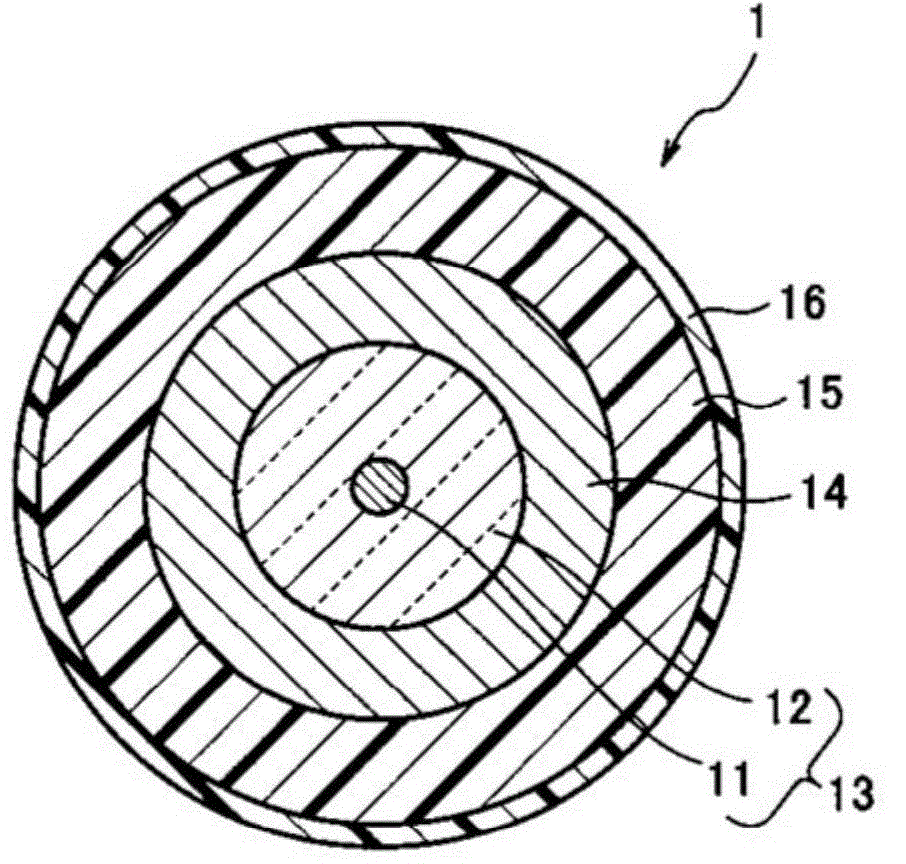

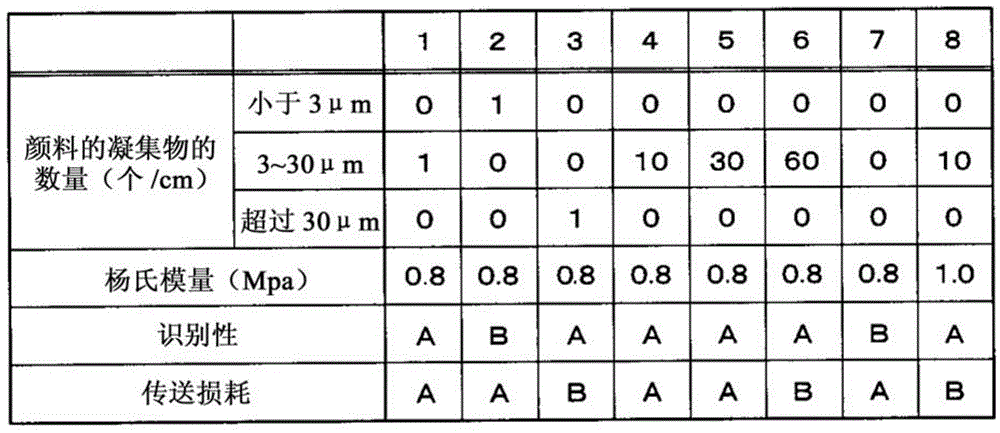

[0015] (1) The invention related to the colored optical fiber core wire of the present application is a colored optical fiber core wire in which the outer periphery of an optical fiber composed of a core and a cladding layer is coated with a multi-layer resin layer, wherein, in the multi-layer resin layer, The outermost resin layer is a coloring layer added with pigments, and each 1 cm in the length direction of the colored core wire of the optical fiber contains more than or equal to one pigment aggregate, and the aggregate size of the pigment is the longest Some are in the range of 3 to 30 μm. Thereby, it is possible to provide a colored optical fiber in which the colored layer is easily recognized in a dark environment such as at night.

[0016] (2) Preferably, every 1 cm of the colored core wire of the optical fiber contains less than or equal to 50 agglomerates of the pigment whose longest part is in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap