Injection mold with hot runner distributor

一种注塑模具、热流道的技术,应用在具有热流道分配器的注塑模具领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

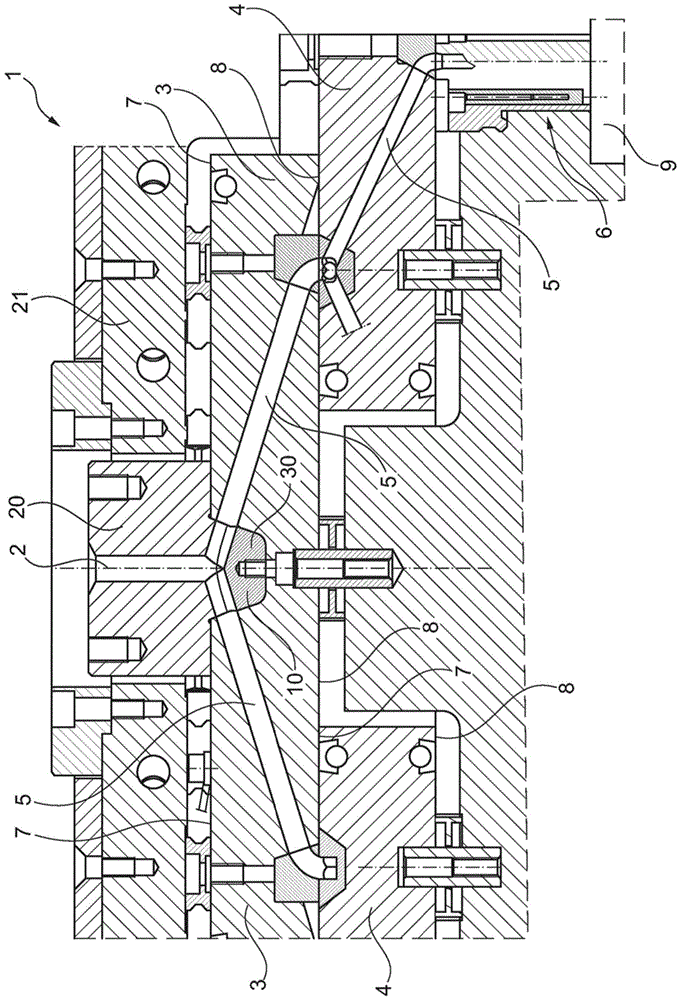

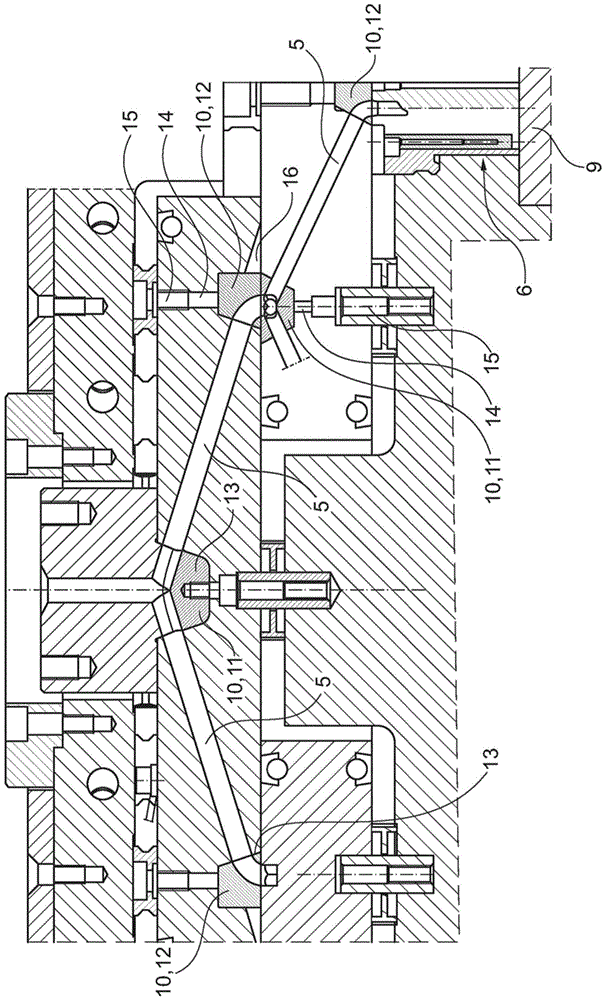

[0011] figure 1 and figure 2 A cross-sectional view of an injection mold according to the invention is shown. The injection mold is denoted by 1 as a whole. At the top, the central supply line 2 can be seen, which is molded in a casting bushing 20 . The casting bushing 20 is held in a fixing plate 21 . Resting against the upper plate 3 is a casting bushing 20 with a central feed line 2 , which is connected to an injection molding device of an extruder or injection molding machine (not shown here). The upper plate is placed flat on the lower plate 4 again. The individual plates are releasably connected to one another by means not discussed further here.

[0012] Heating means are provided in each plate. These heating means may be electrically insulating heating rods or heating channels through which a heating fluid is pumped. Since these heating elements are conventional elements and their configuration is not relevant to the invention, no further description will be gi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com