Steering knuckle casting die cleaning equipment

A technology for casting molds and cleaning equipment, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of steering knuckle casting mold damage, time-consuming and labor-intensive problems, and achieve the effect of overcoming low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

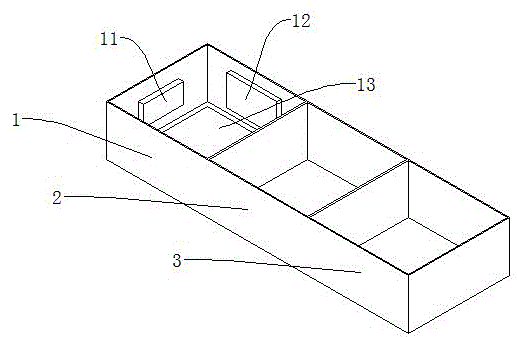

[0013] refer to figure 1 , a steering knuckle casting mold cleaning equipment, comprising a first cleaning tank 1, a second cleaning tank 2, and a third cleaning tank 3; the first cleaning tank is made of stainless steel, and there is a cleaning chamber in the first cleaning tank liquid, the first cleaning tank includes a water inlet and a drain, a thermometer and a heater are arranged in the first cleaning tank, and an ultrasonic vibrating plate group and an ultrasonic generator 11 are also provided inside the first cleaning tank. The ultrasonic generator is electrically connected to the ultrasonic vibrating plate group; the ultrasonic vibrating plate group includes a first vibrating plate 13, a second vibrating plate 12, and a third vibrating plate, and the first vibrating plate is located in the first cleaning tank In the center of the bottom, the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com