Floating mold clamping device for sand core follow-up pallet

A mold clamping device and follow-the-shape technology, which is applied in the direction of mold cores, mold loosening equipment, casting molding equipment, etc., can solve the problems of sand core damage, sand core and sand core follow-up support plate positioning inaccurate, etc., to achieve The effect of ensuring quality, improving accuracy and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiment of the invention will be described in conjunction with the accompanying drawings.

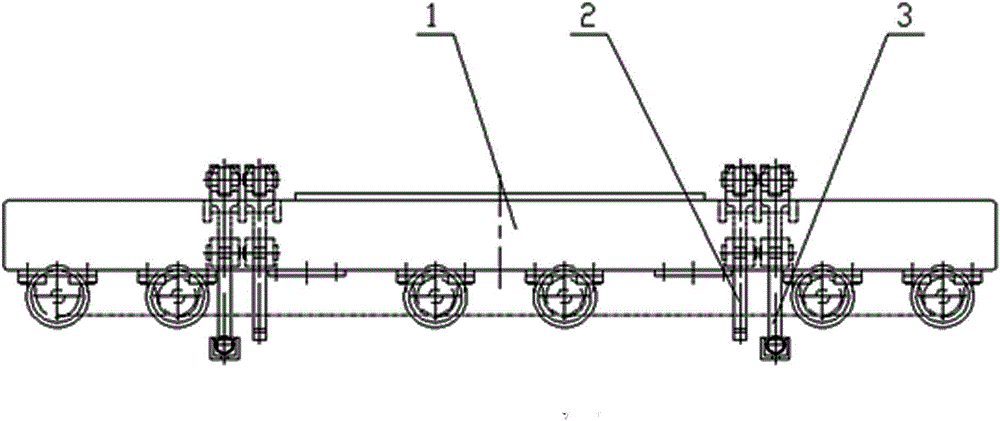

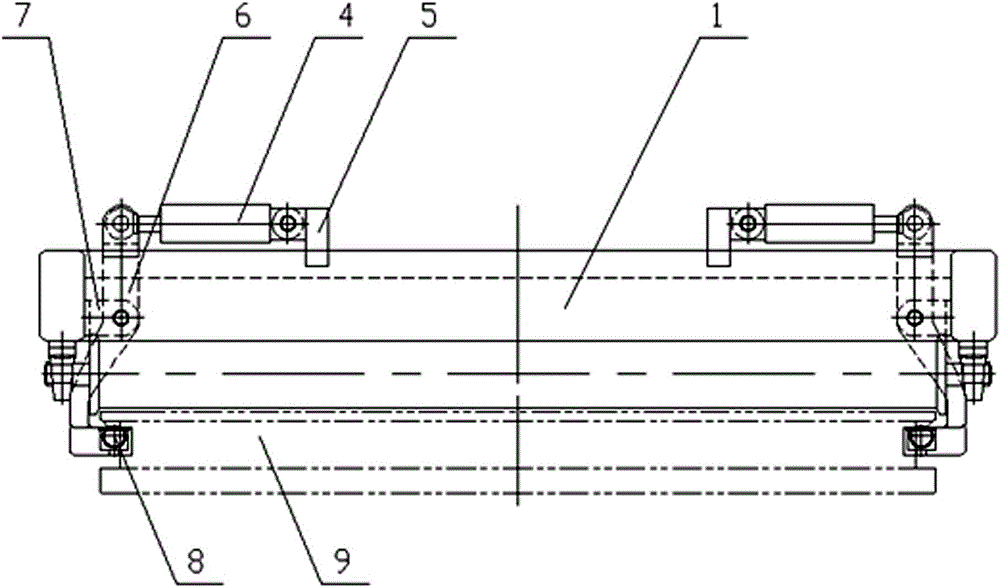

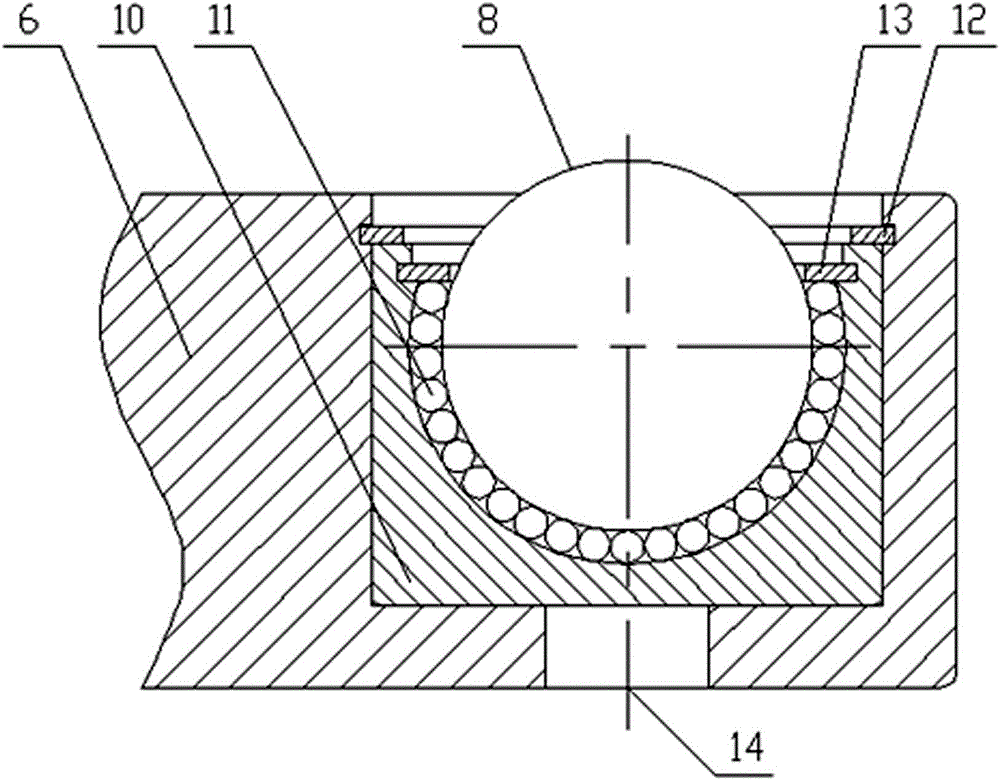

[0012] Such as figure 1 , the floating mold clamping device for the sand core with the shape supporting plate includes an upper roller table 1, the upper roller table 1 has a rectangular roller table frame composed of horizontal and longitudinal beams, the roller body is assembled under the roller table frame through a bearing with a seat, The roller bodies are arranged longitudinally and horizontally in a row. The front and rear sides of the upper roller table 1 are respectively provided with a sand core follow-up pallet locking mechanism 2, and the sand core follow-up pallet lock mechanism 2 has a locking mechanism horizontally placed on the upper roller table 1. Oil cylinder, the rear end of the locking oil cylinder is hingedly connected with the rear seat of the locking oil cylinder fixed on the upper roller table 1, the front end of the locking oil cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com