Floating type armor plate and preparation method thereof

A bullet-proof board and floating technology, which is applied in the direction of chemical instruments and methods, armor plate structure, synthetic resin layered products, etc., can solve the problems that the bullet-proof board does not have the floating ability and the back is too sunken after being shot, and achieves the goal of manufacturing The effect of smooth process, low cost and simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

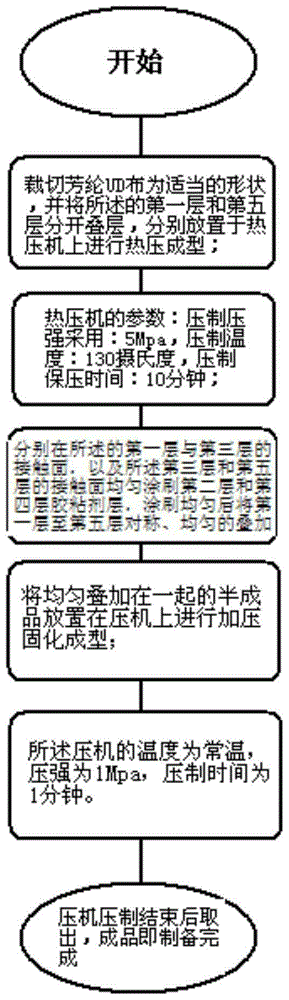

[0026] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

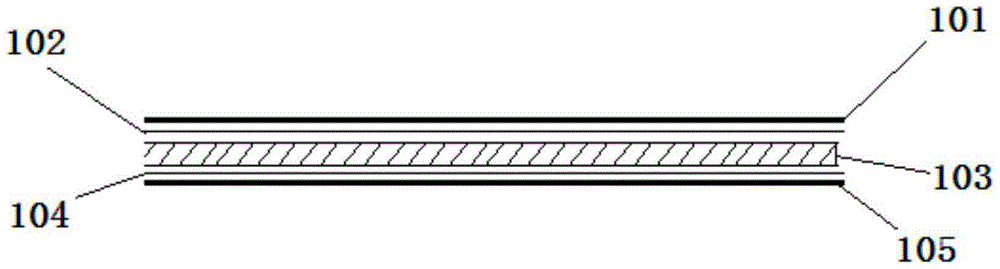

[0027] refer to figure 1 Shown, a kind of floating bulletproof board, this bulletproof board comprises five layers of structure:

[0028] The first layer 101 is an aramid bulletproof plate layer, which is made of aramid bulletproof material and prepared by hot pressing;

[0029] The second layer 102 is an adhesive layer, mainly used for bonding the first layer 101 and the third layer 103;

[0030] The third layer 103 is a foam material layer; this layer has relatively large buoyancy and strong elastic recovery force, and is mainly used for floating on the water surface and buffering and shape recovery after being shot;

[0031] As an example, the foam material layer is: one or a combination of PE foam material, EVA foam material or PP foam material;

[0032] According to different actual needs, the foaming material layer can be prepared wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com