Pulse hand drill

A hand drill and pulse technology, applied in other manufacturing equipment/tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve problems affecting drilling quality and efficiency, hand drill deflection, arm muscles and joints The problem of different force directions can be solved to achieve the effect of improving the drilling quality and speed and making it easy for muscle memory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

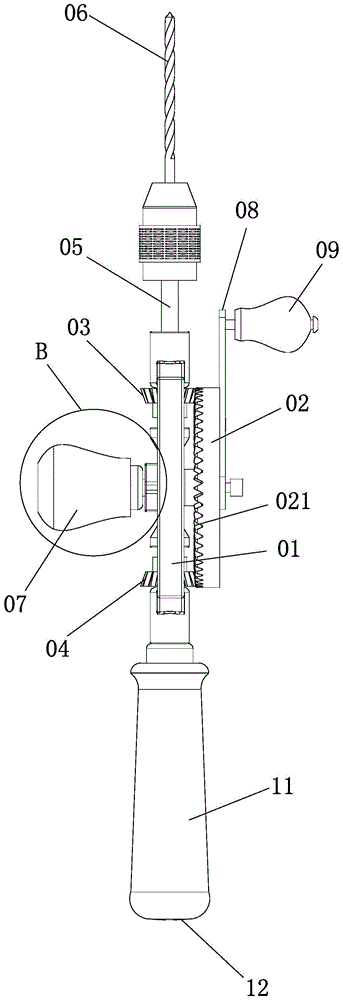

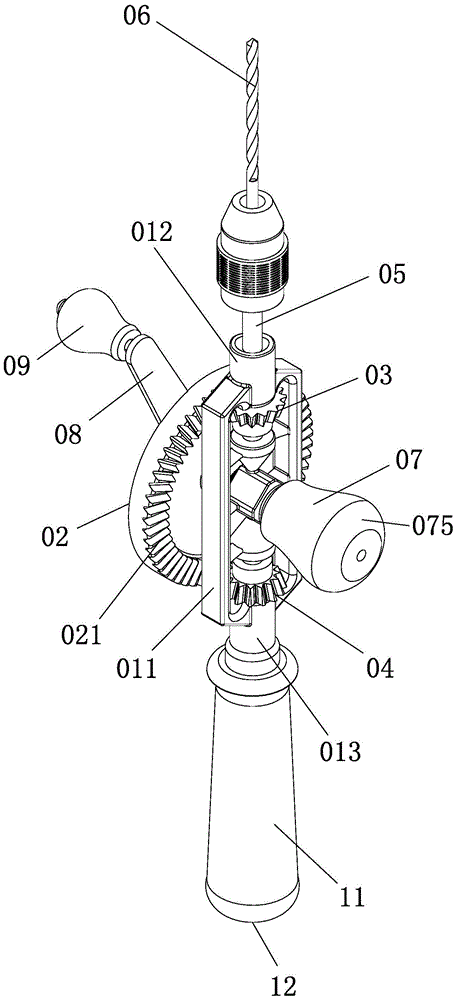

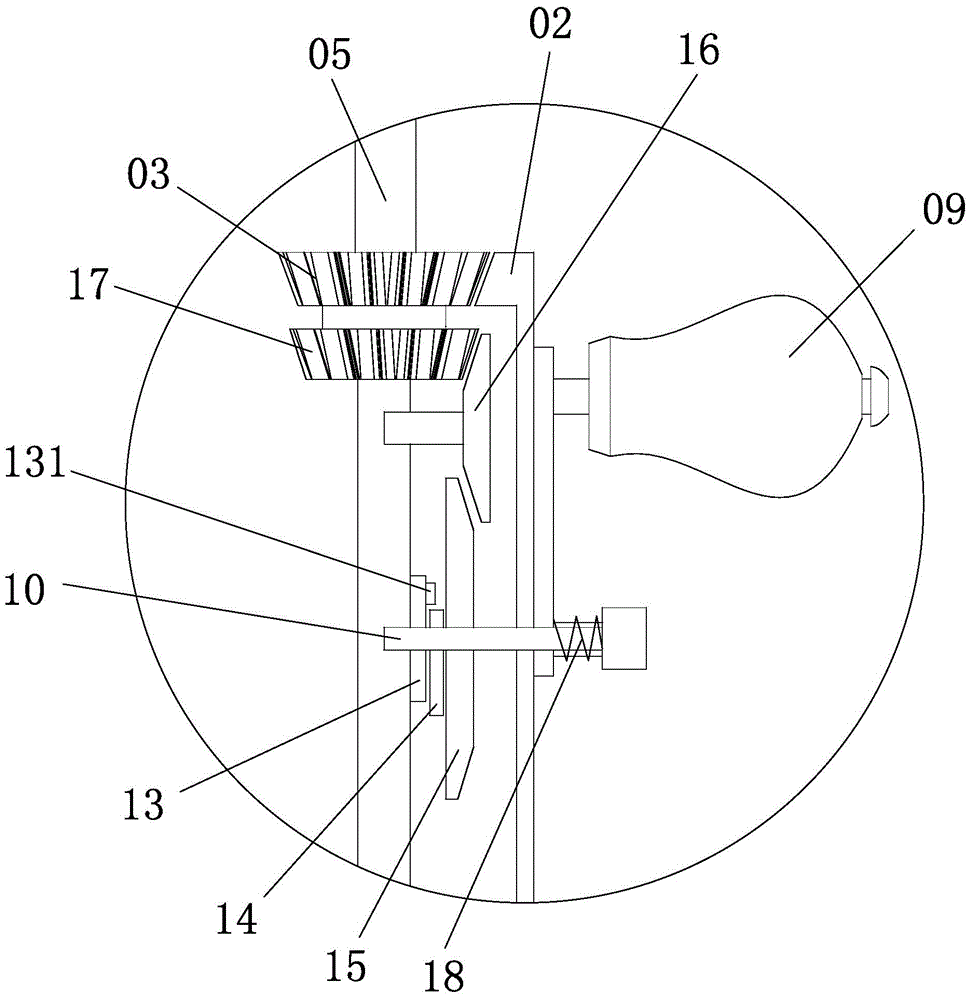

[0029] like figure 1 , 2 . As shown in 3, a hand drill with pulse retraction includes a bracket 01, a main shaft 05 is connected to the bracket for rotation, a drill bit 06 is installed on the free end of the main shaft, a driving bevel gear 03 is set on the main shaft, and a driving bevel gear 03 is set on the bracket. Disk 02, the drive disk is rotationally connected with the bracket through the rotating shaft 10, the axis of the drive disk is perpendicular to the axis of the main shaft, the edge of the drive disk is provided with drive teeth 021, and the drive teeth mesh with the drive bevel gear. A clutch mechanism is arranged at the rotating shaft, and a reversing mechanism is arranged between the rotating shaft and the driving bevel gear. The clutch mechanism includes a fixed disc 13 arranged on the support and a clutch disc sleeved on the rotating shaft. A section of clutch protrusion 131 is arranged on the end face of the fixed disc near the clutch disc, such as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com