Printing apparatus and control program for printing apparatus

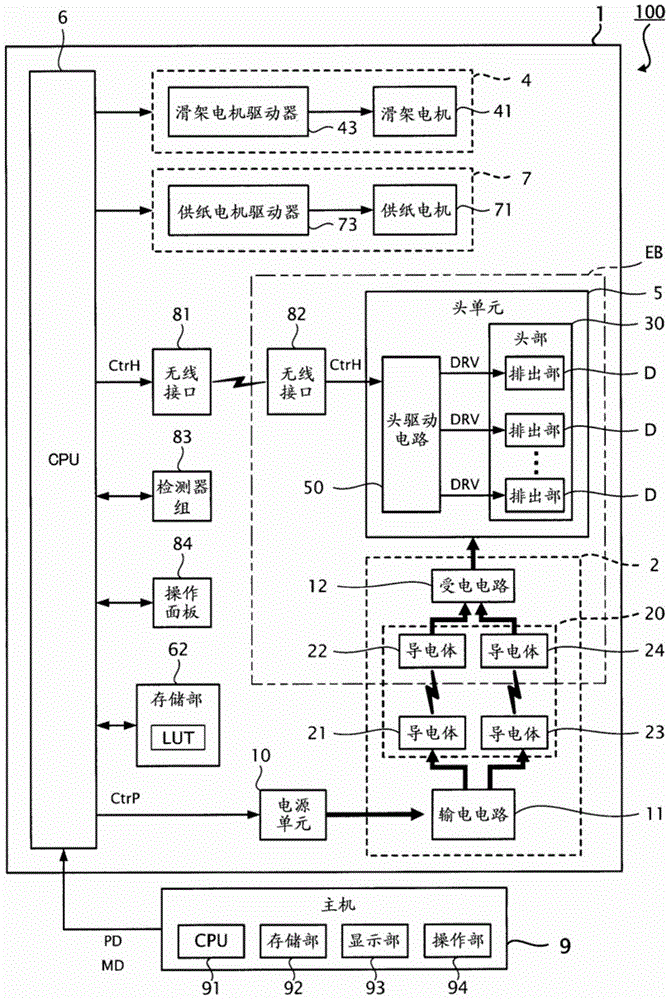

A technology for printing devices and recording media, applied in the directions of printing devices, printing, etc., can solve problems such as wiring noise, and achieve the effect of reducing the possibility of noise generation, preventing the deterioration of printing quality, and reducing the possibility of excessive or insufficient power generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

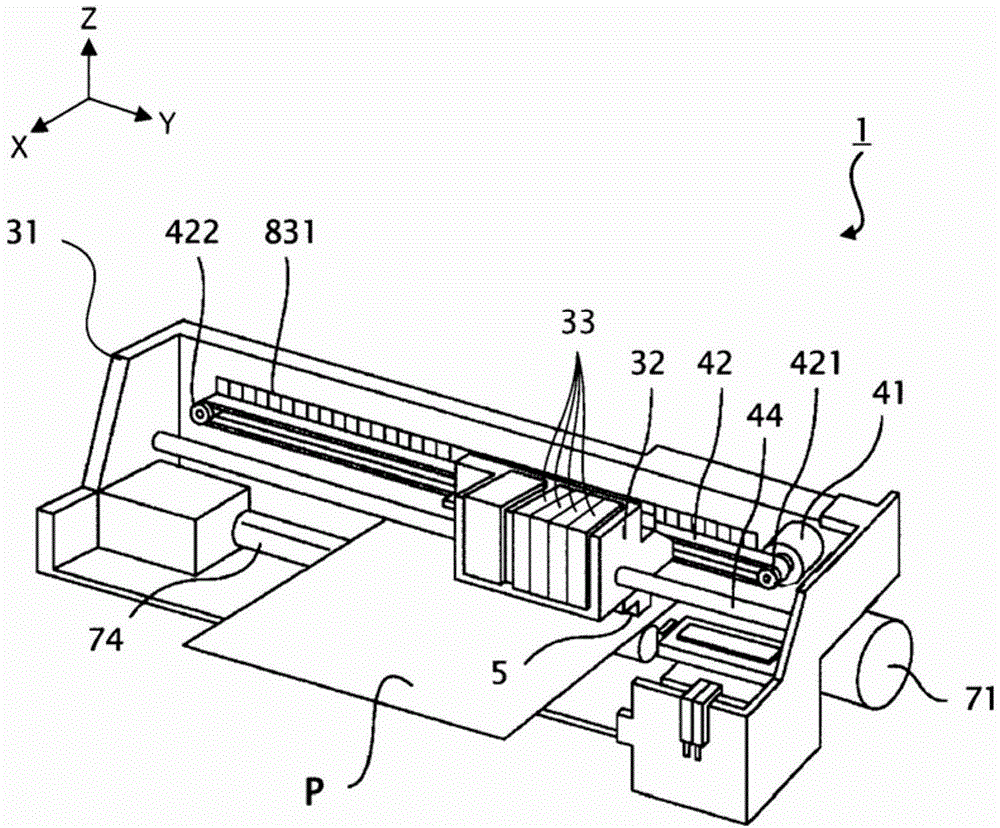

[0237] In the above-mentioned embodiment, both the conductor 21 and the conductor 23 are provided on the lower side of the carriage 32, and on the opposite side of the transport path of the recording medium P when viewed from the carriage 32, but the present invention does not Limited to this aspect, one of the conductor 21 or the conductor 23 may be provided on the frame body 31 or the carriage guide shaft 44 . For example, if Figure 19 As shown, when the conductor 23 is provided on the frame body 31 or the carriage guide shaft 44 , the conductor 24 may be provided at a position facing the conductor 23 on the carriage 32 .

Deformed example 2

[0239] In the above-mentioned embodiments and modified examples, the power transmission unit 2 has the coupling capacitor CM1 on the power supply path and the coupling capacitor CM2 on the discharge path, but the present invention is not limited to this mode, and may only have the coupling capacitor CM1 or the coupling capacitor CM2. One side of capacitor CM2. For example, if Figure 20 As shown, the power transmission unit 2 may have a discharge path set at the ground potential and have a coupling capacitor CM1 only in the power supply path. exist Figure 20 In the example shown, for example, the potential of the carriage guide shaft 44 is set to the ground potential, and the terminal TE32 of the head unit 5 (refer to Figure 8 ) is electrically connected to the carriage guide shaft 44, so that the discharge path can be set to the ground potential. In addition, in Figure 20 In the example shown, the driving method of the power supply path is the same as that of the above...

Deformed example 3

[0241] In the above-mentioned embodiments and modified examples, the power transmission unit 2 transmits power via coupling capacitors (coupling capacitor CM1, coupling capacitor CM2), but the present invention is not limited to this method, and the power transmission unit 2 may also transmit power via at least two conductors. Electromagnetic coupling to transmit electricity.

[0242] For example, an inductance may be used as the conductor 21 and the conductor 22 , and electric power may be transmitted by mutual induction between the conductor 21 and the conductor 22 . In this case, the power supply unit 10 may output the power supply Ws and the power supply voltage VS of a magnitude corresponding to the type of the recording medium P to the power transmission unit 2 . More specifically, the power supply unit 10 may output the supply power Ws and the power supply voltage VS having a magnitude corresponding to the magnetic permeability of the recording medium P to the power tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com