Steering shaft for solid tire flatbed truck and installation method

A technology of solid tires and steering shafts, which is applied to trailer steering mechanisms, steering mechanisms, vehicle components, etc., to achieve the effects of short maintenance time, reduced operation frequency, and not easy to desolder and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

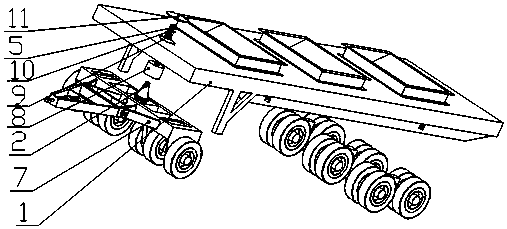

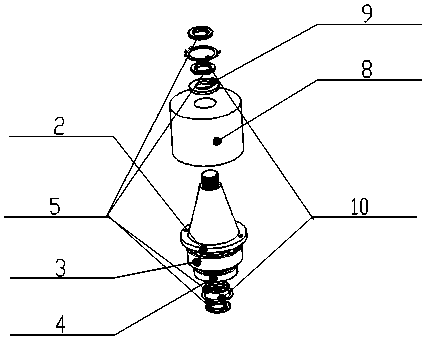

[0018] Example: see figure 1 , 2 , A steering shaft for a solid tire flatbed vehicle, the steering shaft includes a flat plate 1, a steering shaft 2, an embedded conical sleeve 8 is arranged in the middle of the flat plate, and an embedded conical sleeve is sequentially arranged on the upper part of the steering shaft 8. The washer 9, the washer 9 is fixed by a round nut 5, the lower part of the steering shaft 2 is connected with a rotating assembly, the rotating assembly includes an upper bearing 3, a lower bearing 4 and a shaft seat, the lower bearing The lower part of 4 is provided with a stop washer 10 which is sleeved on the steering shaft 2 and fixed by a round nut 5.

[0019] An installation method for the steering shaft of a solid tire flatbed truck, see figure 1 , 2 , The method includes the following steps: 1) Prepare the same steering shaft 2, put one end of the bearing up and the other end down on a wooden board to prevent tooth moment injury, heat the upper bearing 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com