Power roller transmission line

A technology of transmission line and drum, applied in the field of transmission line, can solve the problems of increasing labor intensity of workers, unable to realize automatic operation, etc., and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

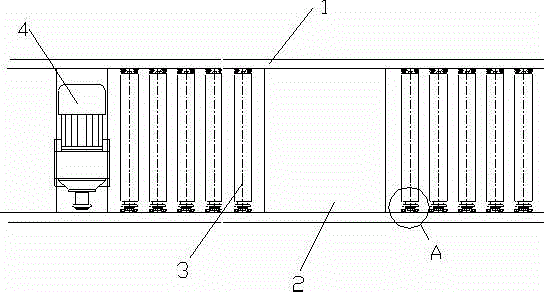

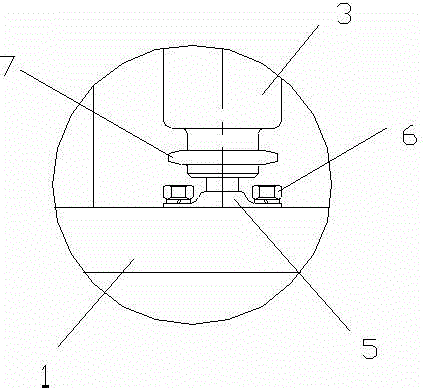

[0012] Such as figure 1 As shown, a power roller transmission line includes a transmission frame 1, a plurality of work table tops 2 are arranged on the transmission frame 1, and a plurality of rollers 3 are arranged at equal intervals between two adjacent work table tops 2 , the two ends of the drum 3 are fixed on the transmission frame 1 through the fixed plate 5 and the lock nut 6, and the drum 3 can rotate axially relative to the fixed plate 5, and the other parts of the drum 3 A pulley 7 is provided at one end, and a motor 4 is provided below the transmission frame 1, and the motor 4 drives the drum 3 through a belt. Driven by the motor 4, the drum 3 is powered and can rotate synchronously and uniformly, so that the product from the previous station is automatically transported to the next station, realizing automatic transportation without manual pulling and red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com