A mobile automatic spray dust suppression system for trestle-type coal storage yard

A spray dust reduction, mobile technology, applied in the directions of dust prevention, loading/unloading, safety devices, etc., can solve the problems of excessive coal dust concentration, large dust range, large water consumption, etc., to reduce treatment costs and reduce dust range. , the effect of saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

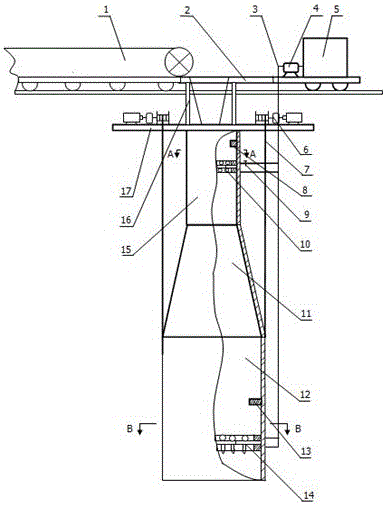

[0028] A mobile automatic spray dust suppression system used in trestle-type coal storage yard. The mobile automatic spray dust suppression system such as figure 1 As shown, a mobile water tank 5 is installed on the track of the mobile belt conveyor 1, the mobile water tank 5 is located in front of the discharge chute of the mobile belt conveyor 1, the wheel frame of the mobile belt conveyor 1 and the wheel frame of the mobile water tank 5 Fixed connection via horizontal connector 2. The system platform 17 is fixedly connected to the horizontal connector 2 through the vertical connector 16, and the middle position of the system platform 17 is provided with a feed inlet, and the feed inlet is located directly below the discharge chute of the mobile belt conveyor 1. The upper end of the upper movable cover 15 is concentrically fixed at the feeding port of the system platform 17, the upper end of the telescopic movable cover 11 is fixedly connected with the lower end of the uppe...

Embodiment 2

[0038] A mobile automatic spray dust suppression system used in trestle-type coal storage yard. Except following technical parameter, all the other are with embodiment 1:

[0039] Three synchronous lifting devices 6 are installed on the upper plane of the system platform 17;

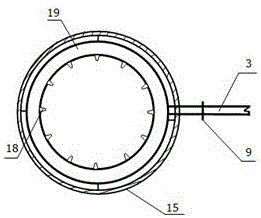

[0040] 10-11 or 13-30 upper nozzles 18 are evenly installed inwardly in the radial direction on each upper annular water pipe 19;

[0041] A solenoid valve 9 is installed between the lower upper annular water pipe 19 and the high-pressure water pipe 3 in the upper annular water pipe 19 of the second layer;

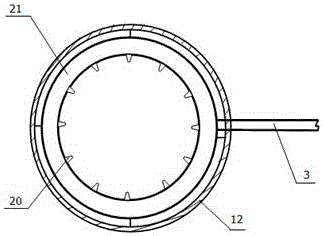

[0042] Each layer of lower annular water pipes 21 is evenly equipped with lower 10-11 or 13-50 lower nozzles 20 inwardly along the radial direction;

[0043] The diameter of the upper movable cover 15 is 2.0~3.0m, and the ratio of the diameter of the lower movable cover 12 to the diameter of the upper movable cover 15 is (2.0~2.5):1.

[0044] The use status of this specific embodiment is as Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com