Fixed connection device for full-automatic material-connecting roller of color press

A color printing machine, fully automatic technology, applied in the direction of thin material processing, transportation and packaging, winding strips, etc., can solve the problems of low efficiency, inconvenient replacement of rollers, and weak fixed connection of rollers, etc., to improve work Efficiency and easy replacement of rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

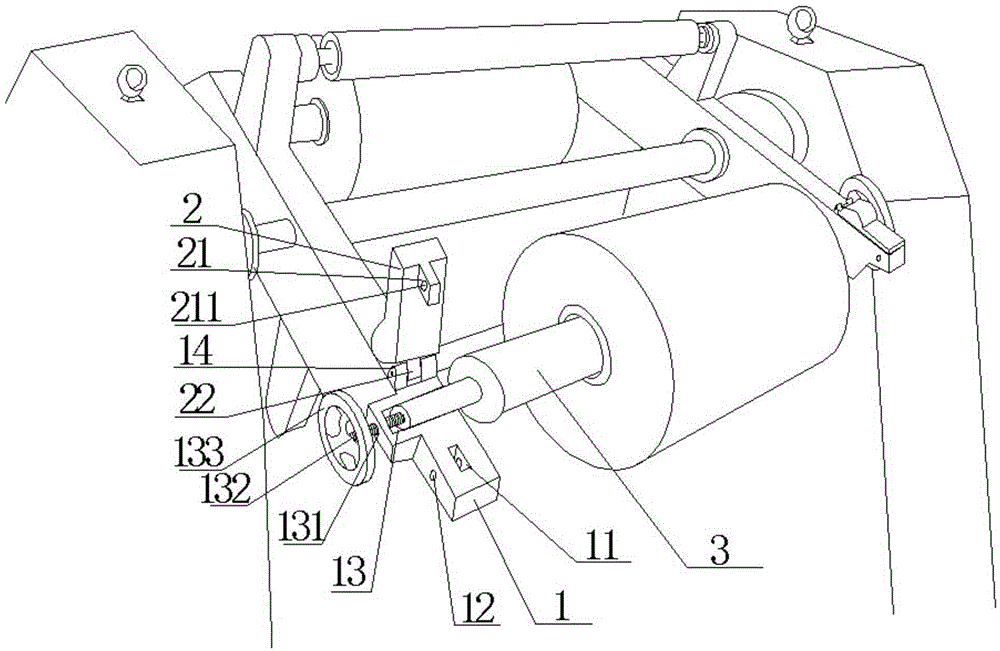

[0015] Such as figure 1 It is a fixed connection device for the rotary roller of the automatic material receiving color printing machine, which is generally arranged at both ends of the automatic material receiving upper rotating roller, and is used to fixedly connect the rotating roller to the automatic material receiving device of the color printing machine. The full-automatic material receiving color printing machine roller fixed connection device includes a metal support plate 1 and a cover plate 2. The support plate 1 is provided with a square concave hole 11, a longitudinal concave hole 13, and a raised ear plate 14, wherein the square The concave hole 11 is at the front, the longitudinal concave 13 is in the center, and the raised ear plate 14 is at the rear.

[0016] The rear end of the cover plate 2 is provided with a protruding end 22, and the protruding end 22 is connected with the two protruding lugs 14 by screws, and the cover plate 2 can be connected with the con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap