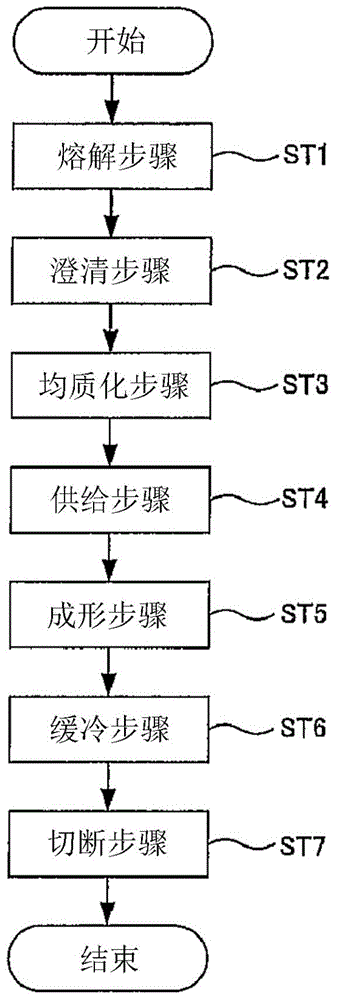

Method for manufacturing glass substrate and device for manufacturing glass substrate

A glass substrate and manufacturing method technology, applied in glass manufacturing equipment, glass molding, glass molding and other directions, can solve the problems of falling, the increase of the risk of shaft deformation, etc., and achieve the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

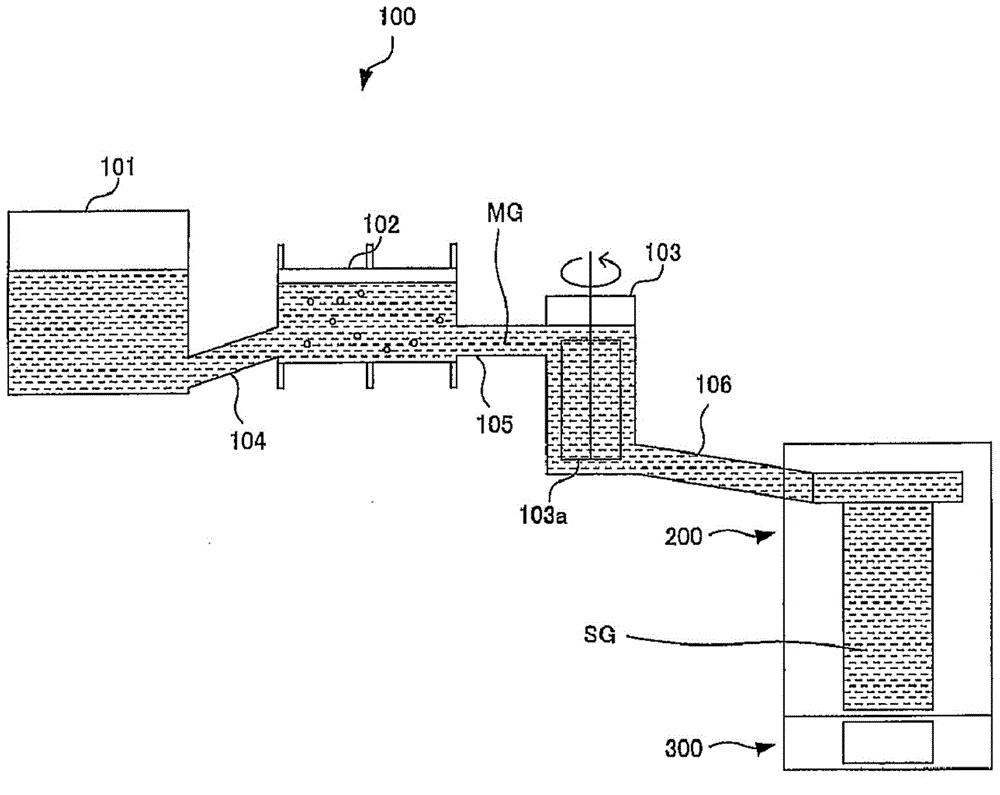

Method used

Image

Examples

Example Embodiment

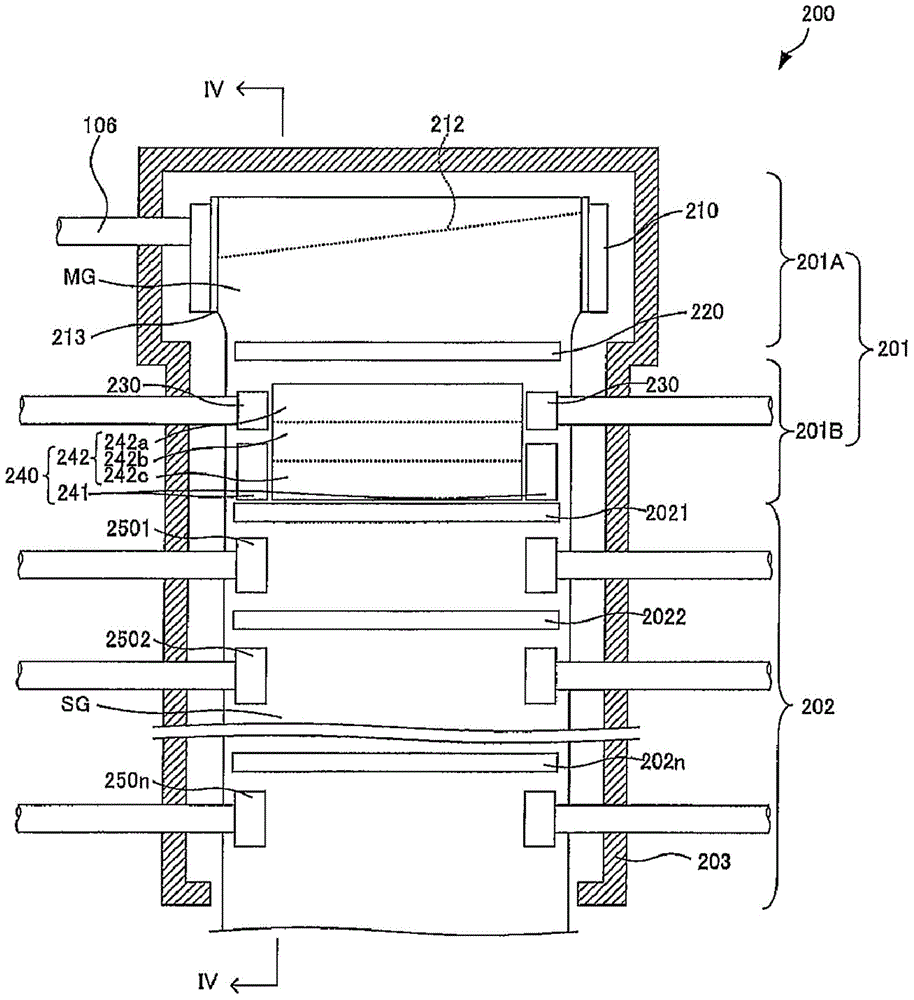

[0095] [Example]

[0096] Hereinafter, the present invention will be explained more specifically through examples.

[0097] Set the rotation axis of the conveying part in the slow cooling furnace as the above Figure 5 The construction shown. The length of the insulating material in the longitudinal direction of the rotating shaft from the furnace wall is set to 0.26m, the temperature in the slow cooling furnace is set to 800°C, and the temperature outside the slow cooling furnace is set to 30°C. The heat conduction of the rotating shaft The rate is assumed to be SUS304 and set the thermal conductivity W / (m·K) = 0.013*temperature (℃)+15, and the thermal conductivity of the insulation material is set to 0.1W / (m·K) to calculate the rotation Allowable stress of the shaft.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap