Float process for producing a float glass pane and a float glass pane

A float process and glass plate technology, applied in the field of float glass plates, can solve the problems of different chemistry and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

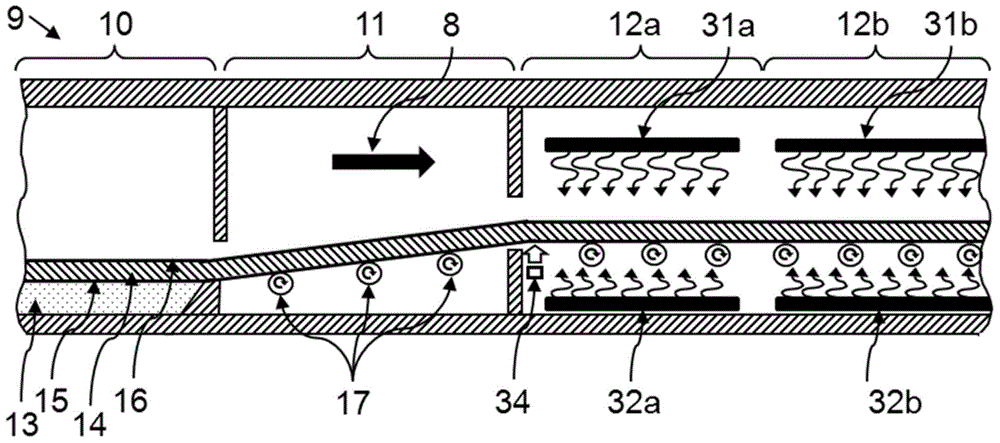

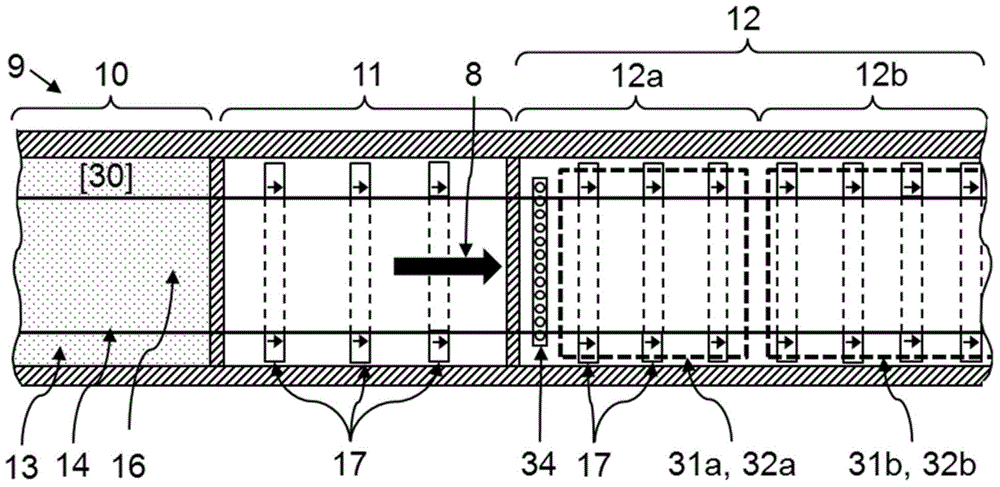

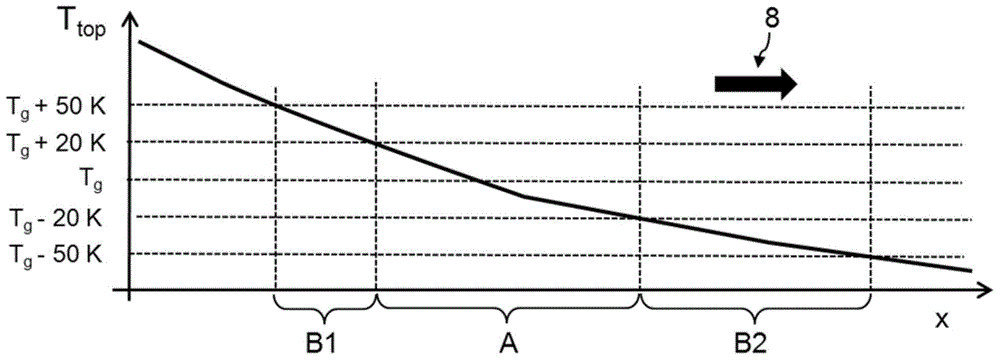

[0085] exist figure 1A cross-section of the relevant part of a float glass plant suitable for carrying out the method according to the invention is schematically shown in . The stretching zone (9) comprises in the stretching direction (8) the end of the float kiln (10) with the molten metal (13), the tin bath box (11) and the annealing kiln (12), in which the tin bath The glass ribbon (14) in the box (11) having the tin bath side (15) and the upper side (16) after leaving the molten metal (13) runs on a first transport roll (17) in which the lehr (12 ) the glass ribbon (14) is cooled to a low stress state. The lehr (12) has sections (12a, 12b) arranged in tandem in which the glass ribbon (14) has been subjected to a heat output P from above by means of upper electric heating elements (31a, 31b) n,above , and is subjected to heat output P from below by the lower electric heating elements (32a, 32b) n,below . The electric heating elements ( 31 , 32 ) are in this case of con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap