An expansion resonance compound muffler

A muffler and composite technology, applied in the field of vibration reduction and noise reduction, can solve the problems of unsatisfactory noise reduction effect of low-frequency noise, large engine power loss, large exhaust back pressure, etc., to achieve small pressure loss, large noise reduction, wide The effect of the anechoic band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

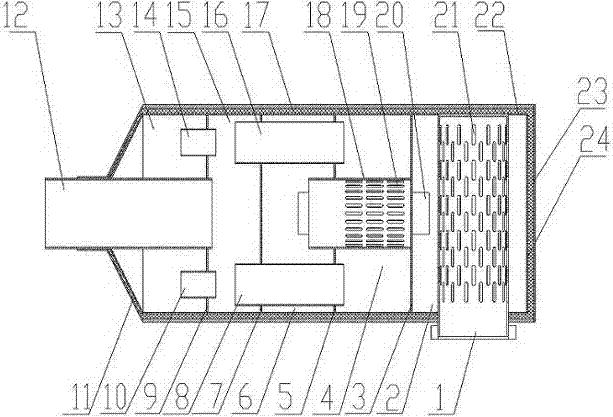

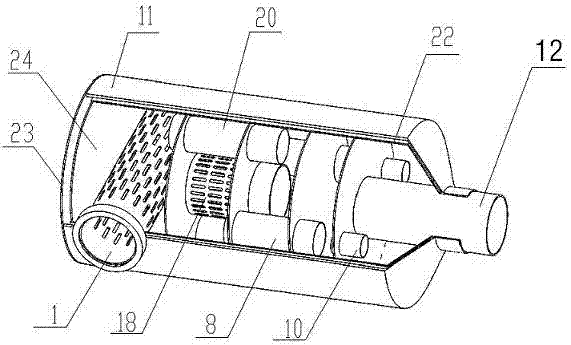

[0025] Such as figure 1 and figure 2 Shown: an impedance compound muffler of the present invention, including an outer cylinder 11, an inner cylinder 22, an outer end cover 23, an inner end cover 24, an air inlet pipe 1, an air outlet pipe 12, a partition I3, a partition II5, and a partition III7 , Separator IV 9, perforated tube 18, intermediate tubes 8, 16, resonance cavity insertion tubes 10, 14, inner insertion tube 20, etc.

[0026] The outer cylinder 11 is sheathed outside the inner cylinder 22 and is coaxial with the inner cylinder 22 , and a heat insulating material 17 is filled between the outer cylinder 11 and the inner cylinder 22 .

[0027] One end of the outer cylinder 11 and the inner cylinder 22 is closed by the outer end cover 23 and the inner end cover 24 respectively, and an air inlet pipe 1 extending radially into the inner cylinder 22 and reaching the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com