Automobile silencer

A technology of automobile mufflers and chambers, applied in the direction of mufflers, machines/engines, engine components, etc., can solve the problems of poor muffler effect and short service life, reduce pulsation performance, attenuate high-frequency noise, and improve low-frequency muffler The effect of sound performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

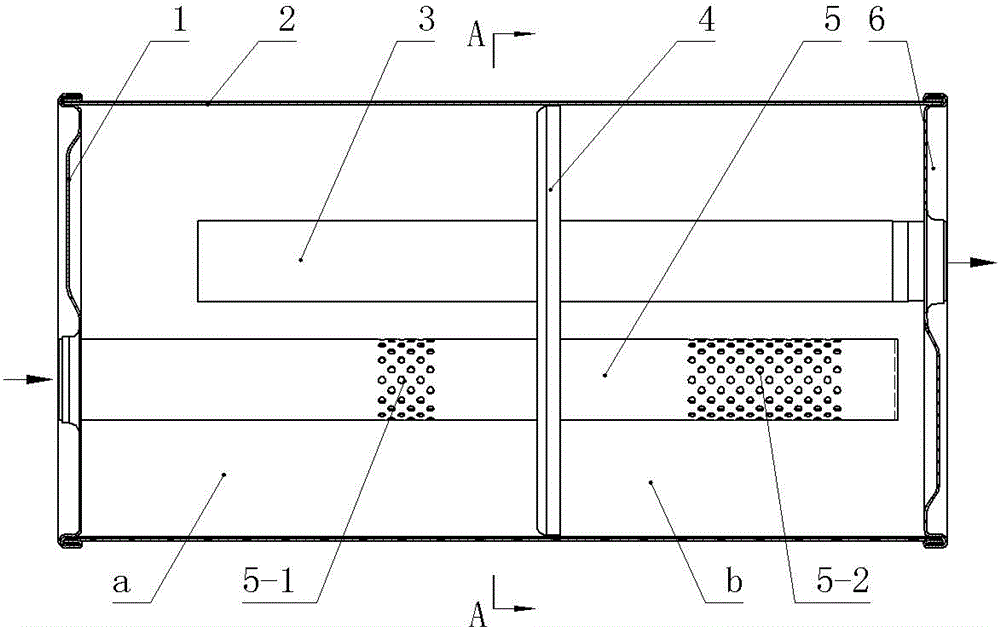

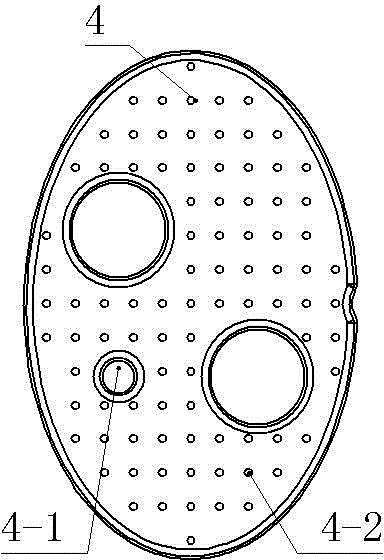

[0013] Such as figure 1 and figure 2 The automobile muffler shown includes a shell provided with an air inlet pipe 5 and an air outlet pipe 3. The shell is formed by connecting a front end cover 1, a rear end cover 6 and a cylinder body 2. The cylinder body 2 is surrounded by two layers of overlapping steel plate lock seams. The two layers of steel plates have the same thickness and are 0.6 mm. The connections between the cylinder body 2 and the front end cover 1 and the rear end cover 6 are end cover crimping connections, and a drainage through hole is provided on the edge of the rear end cover 6; The inner space is divided into the first chamber a and the second chamber b by a partition plate 4 with holes along the air intake direction, the end of the intake pipe 5 is blocked and extends into the second chamber b through the partition plate 4, The inlet pipe 5 has a plurality of through holes distributed on the pipe walls of the first chamber a and the second chamber b, an...

Embodiment 2

[0015] The number of through holes on the wall of the second chamber b of the inlet pipe 5 is 3 times the number of through holes on the wall of the first chamber a; in this embodiment, the holes on the partition plate 4 are multiple and evenly distributed, and the holes The diameter is 3 millimeters; Present embodiment also has a diameter on the spacer 4 and is the large hole of 20 millimeters, and other characteristics are identical with embodiment 1.

[0016] During work, the airflow enters from the air inlet pipe 5, and the airflow that enters flows out from the through holes on the pipe wall of the first chamber a and the second chamber b respectively from the air inlet pipe 5, because the air inlet pipe 5 is on the pipe wall of the second chamber The number of upper through holes is 2 to 3 times the number of through holes on the wall of the first chamber, and the sum of the equivalent areas of the through holes separated by the two parts of the intake pipe is 1.8 to 2.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com