Wire icing thickness measurement and equivalent conversion method in phytotron

An artificial climate chamber and ice thickness technology, applied in the field of value conversion, can solve the problem of inability to measure the ice thickness continuously, and achieve the effect of shortening the ice coating test time, small calculation amount, and strong practicability.

Active Publication Date: 2015-09-30

STATE GRID CORP OF CHINA +2

View PDF7 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The technical problem to be solved by the present invention is to provide a method for measuring and equivalent conversion of ice thickness of wires in an artificial climate chamber for the problem that the traditional wire ice coating measurement method cannot continuously measure ice thickness. Measuring the ice coating thickness of conductors, the measurement method is simple, efficient and easy to implement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0059] Take the icing test of LGJ-400 / 50 wires commonly used in power grids as an example.

[0060] (1) Conversion of wire radius.

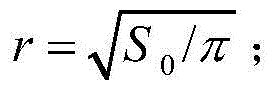

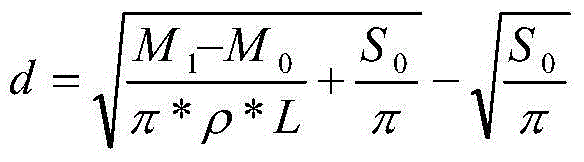

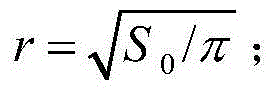

[0061] According to the cross-sectional area S of the wire 0 is 400 square millimeters, the radius r of the wire is calculated as:

[0062]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a wire icing thickness measurement and equivalent conversion method in a phytotron. The method comprises steps as follows: (1) calculating the radius of a wire and measuring the quality and the length of the wire; (2) performing icing on the wire; (3) measuring and converting the icing quality of the wire; (4) calculating the icing volume of the wire; (5) calculating the icing thickness of the wire; (6) repeating steps (2) to (5) and continuously calculating the icing thickness of the wire. With the adoption of the method, the icing thickness of the wire can be measured quickly and continuously, and the measuring method is simple, efficient and easy to implement.

Description

technical field [0001] The invention belongs to the technical field of electrical engineering, and in particular relates to a method for measuring and equivalently converting the ice thickness of wires in an artificial climate chamber. Background technique [0002] Affected by special geographical and climate characteristics, power grid freezing disasters frequently occur in southern China and a few northern regions. In order to grasp the characteristics and laws of power grid icing and provide a theoretical basis for power grid anti-icing work, relevant scholars at home and abroad have carried out power transmission in artificial climate chambers. Experimental research on ice coating growth of line conductors. A basic task of this experimental study is to measure the ice thickness of the wire. [0003] However, there are two main methods for measuring the icing thickness of conductors commonly used at present: one method is to directly measure the icing thickness of conduc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B21/08

CPCG01B21/08

Inventor 陆佳政张红先李波方针

Owner STATE GRID CORP OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com