Fault diagnosis method by combining correlation analysis and data fusion

A technology of data fusion and fault diagnosis, which is applied to instruments, electrical testing/monitoring, control/regulation systems, etc., and can solve problems such as low accuracy of fault diagnosis results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

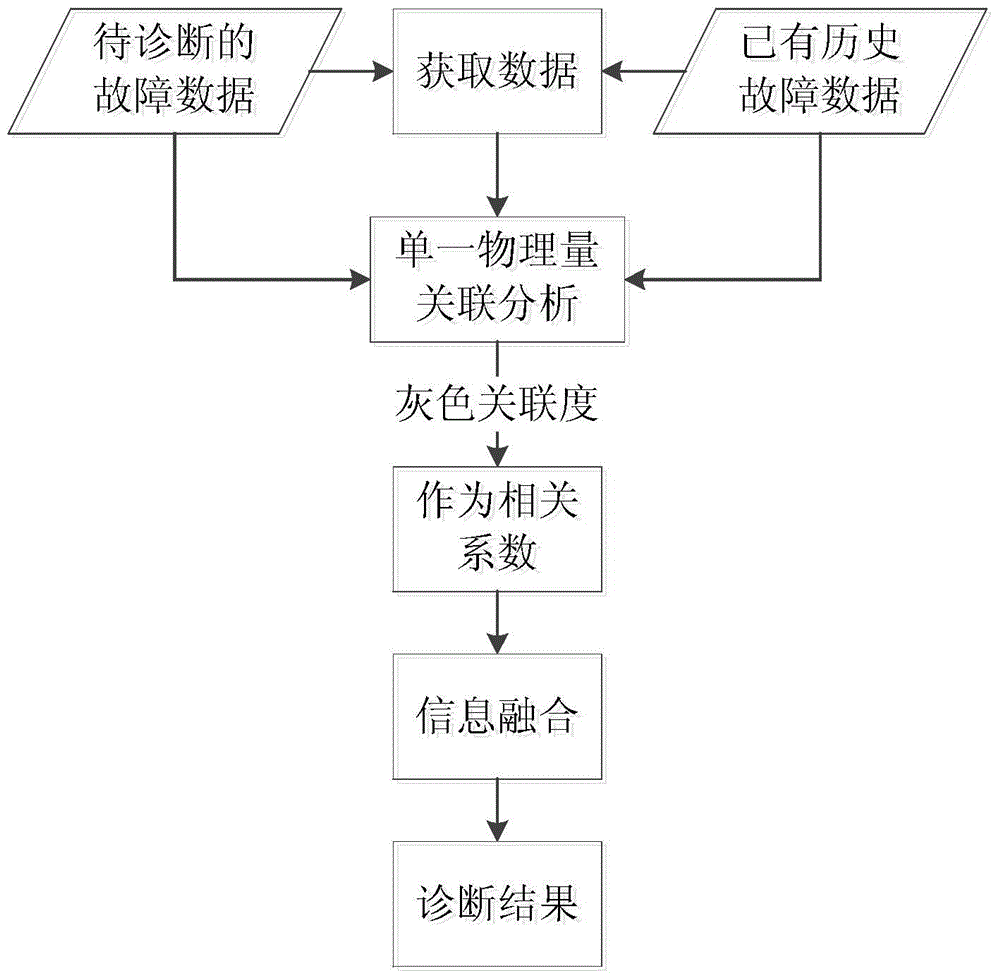

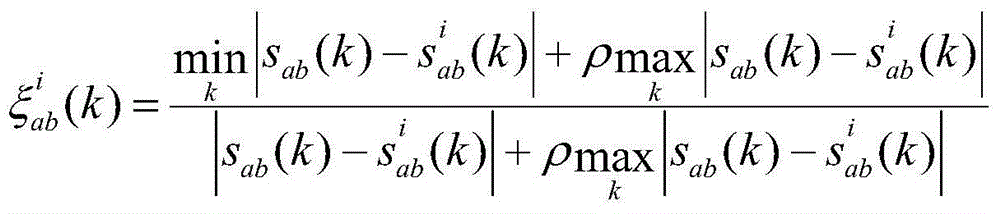

[0029] refer to figure 1 . The specific steps of the fault diagnosis method combined with correlation analysis and data fusion of the present invention are as follows:

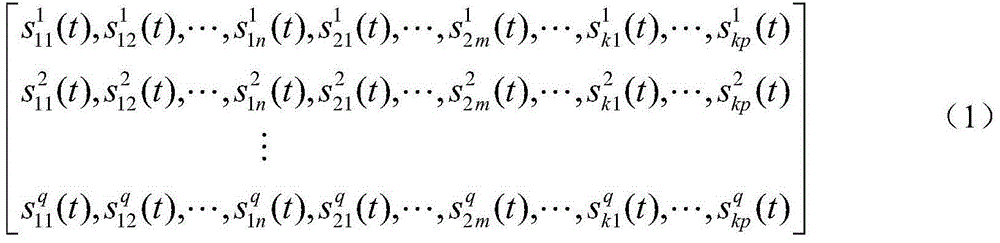

[0030] Step 1. Obtaining data and data preprocessing. It is known that the fault data to be diagnosed includes physical quantities output by N equipment. These physical quantities are distributed in k subsystems of the equipment, and the physical quantities output by each subsystem are different. During the historical operation of the equipment, there are q types of known faults. For the known fault modes of type q, the output physical quantity corresponding to the data type of the fault to be diagnosed is obtained one-to-one. For the equipment to be tested, the physical quantities output by each main system of the equipment when the known q-type faults occurred in the historical operation process are extracted, such as the time series of voltage, temperature, and deflection angle.

[0031] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com