Cylindrical solar cell assembly

A solar cell and columnar technology, applied in the field of solar cells, can solve problems such as rising solar cell manufacturing costs, achieve the effects of reducing construction costs, improving light trapping effects, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

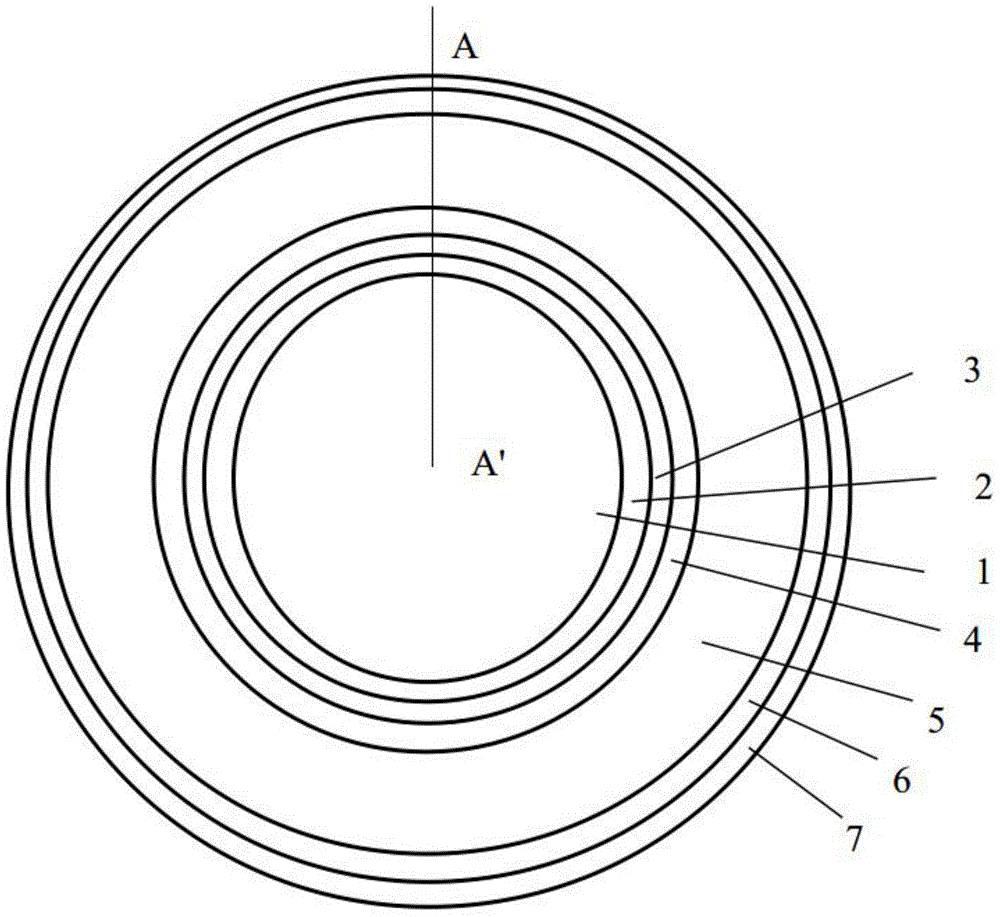

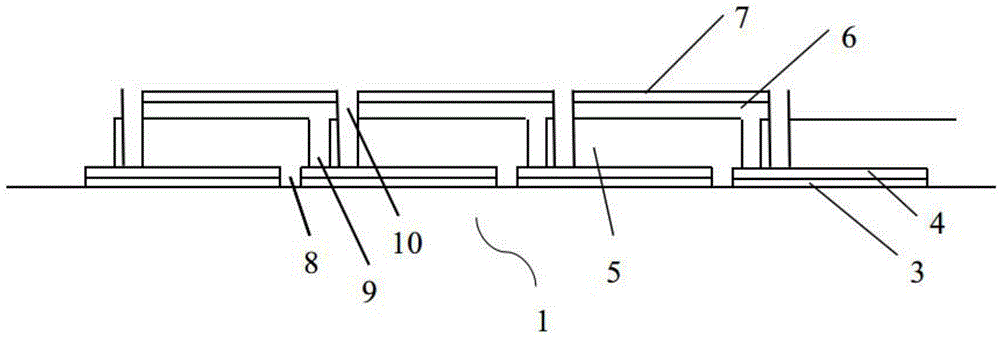

[0026] Such as figure 1 and figure 2 As shown, the present invention provides a cylindrical solar cell assembly, including a cylindrical solar cell and an encapsulation backplane, and the cylindrical solar cell includes a substrate 1, a bottom electrode 3, a bottom transparent conductive layer 4, a functional layer 5, and a top layer Transparent conductive layer 6, gate electrode layer 7;

[0027] The base 1 is a columnar base 1, the bottom electrode 3, the bottom transparent conductive layer 4, the functional layer 5, the top transparent conductive layer 6, and the gate electrode layer 7 are sequentially formed on the base 1, and the bottom electrode 3 There is a first groove 8 in the bottom transparent conductive layer 4, a second groove 9 in the functional layer 5, and a third groove 10 in the top transparent conductive layer 6 and the gate electrode layer 7;

[0028] The top transparent conductive layer 6 includes a first transparent conductive layer and a second transp...

Embodiment 2

[0040] Such as figure 1 and figure 2 As shown, the present invention provides a cylindrical solar cell assembly, including a cylindrical solar cell and an encapsulation backplane, and the cylindrical solar cell includes a substrate 1, a bottom electrode 3, a bottom transparent conductive layer 4, a functional layer 5, and a top layer Transparent conductive layer 6, gate electrode layer 7;

[0041] The base 1 is a columnar base 1, the bottom electrode 3, the bottom transparent conductive layer 4, the functional layer 5, the top transparent conductive layer 6, and the gate electrode layer 7 are sequentially formed on the base 1, and the bottom electrode 3 There is a first groove 8 in the bottom transparent conductive layer 4, a second groove 9 in the functional layer 5, and a third groove 10 in the top transparent conductive layer 6 and the gate electrode layer 7;

[0042] The top transparent conductive layer 6 includes a first transparent conductive layer and a second transp...

Embodiment 3

[0055] Such as figure 1 and figure 2 As shown, the present invention provides a cylindrical solar cell assembly, including a cylindrical solar cell and an encapsulation backplane, and the cylindrical solar cell includes a substrate 1, a bottom electrode 3, a bottom transparent conductive layer 4, a functional layer 5, and a top layer Transparent conductive layer 6, gate electrode layer 7;

[0056]The base 1 is a columnar base 1, the bottom electrode 3, the bottom transparent conductive layer 4, the functional layer 5, the top transparent conductive layer 6, and the gate electrode layer 7 are sequentially formed on the base 1, and the bottom electrode 3 There is a first groove 8 in the bottom transparent conductive layer 4, a second groove 9 in the functional layer 5, and a third groove 10 in the top transparent conductive layer 6 and the gate electrode layer 7;

[0057] The top transparent conductive layer 6 includes a first transparent conductive layer and a second transpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandgap | aaaaa | aaaaa |

| Bandgap | aaaaa | aaaaa |

| Bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap