Improved MMC (modular multi-level converter) structure with direct current fault clearing capacity

A modular multi-level, DC fault technology, used in emergency protection circuit devices for limiting overcurrent/overvoltage, output power conversion devices, AC power input conversion to DC power output and other directions, can solve the problem of double thyristor Insufficient protection range, slow fault isolation speed, limited fault types, etc., to achieve the effect of increasing the protection range, accelerating the decay speed of fault current, and reducing overcurrent hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

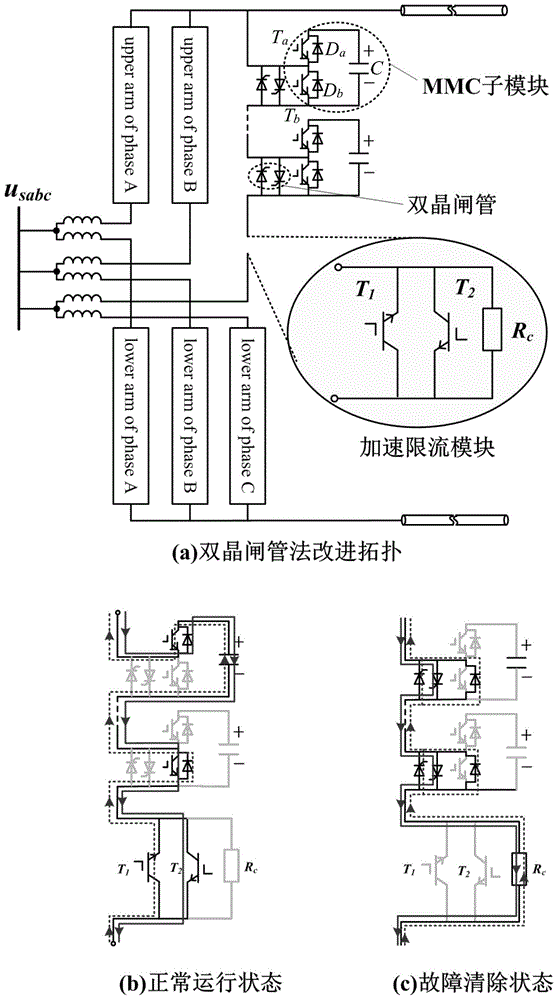

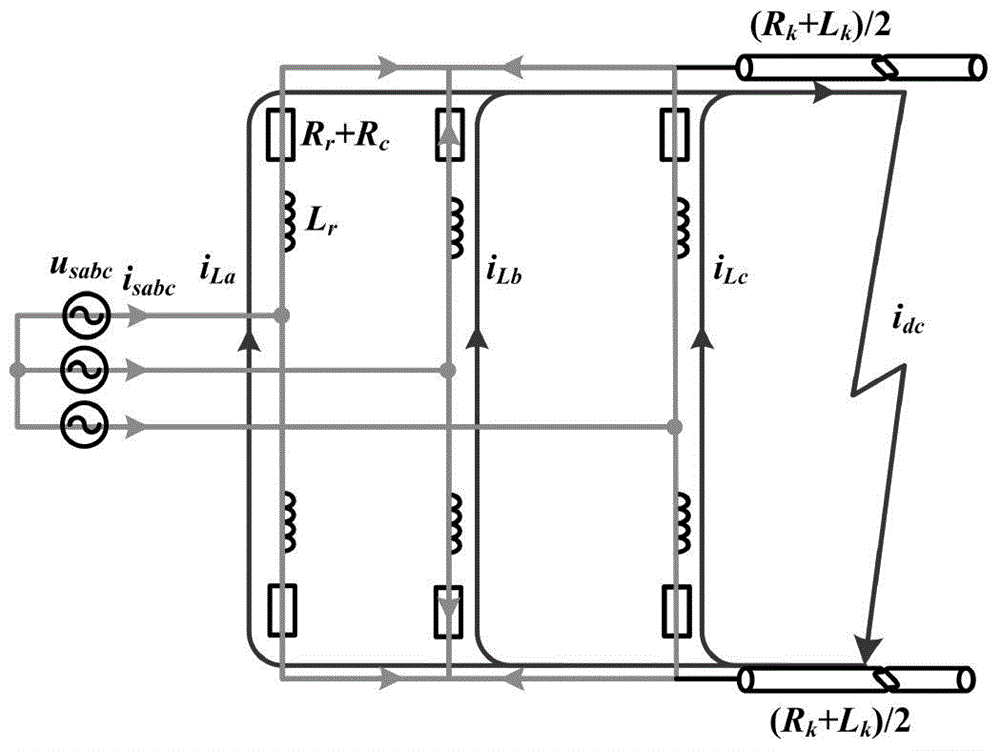

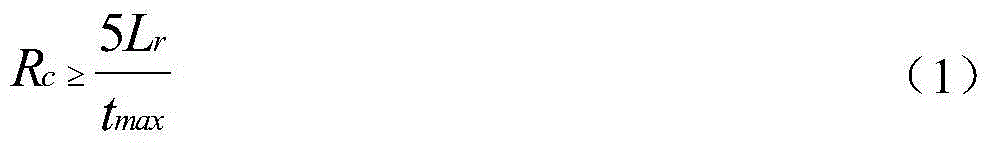

[0016] Some improvements are made to the topology of the Modular Multilevel Converter (MMC) based on the dual thyristor method, such as figure 1 As shown in (a): the double thyristor method adds anti-parallel double thyristors in each MMC sub-module of the MMC converter. On this basis, the present invention connects an accelerated current limiting module in series in each bridge arm of the MMC , the module consists of two anti-parallel IGBTs and a parallel resistor R c constitute. In the picture: T 1 , T 2 For anti-parallel IGBTs, R c It is the resistor connected in series on the bridge arm of the converter after the fault occurs.

[0017] When the DC system is running normally, the IGBTs of the acceleration current limiting modules connected in series in each bridge arm are in the on state. At this tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com