A method and device for forming a slotted self-locking nut

A self-locking nut and locking technology, applied in the direction of nuts, forming tools, threaded fasteners, etc., can solve the problems of poor product accuracy, difficult and uniform closing value of locking flaps, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

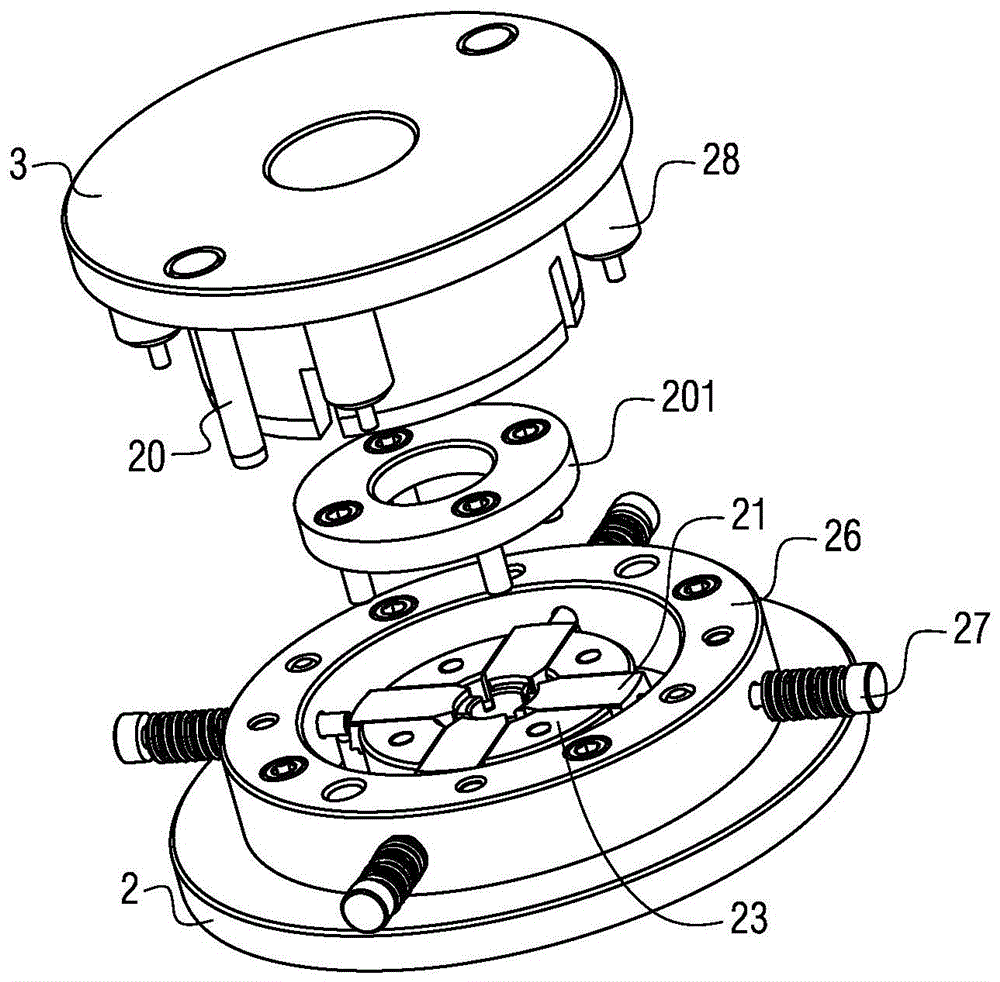

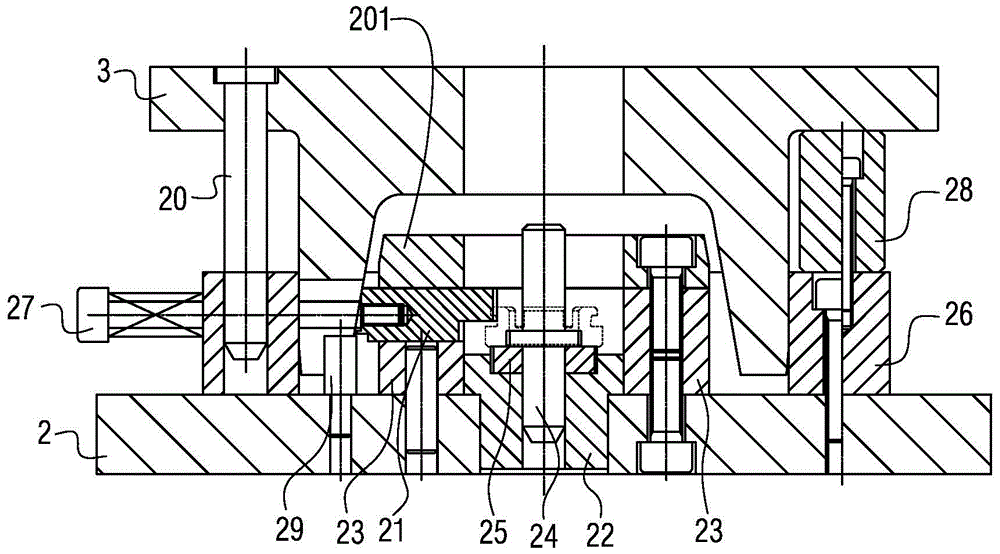

[0021] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

[0022] In order to solve the technical problems existing in the existing slotted self-locking nut closing process, the present invention provides a slotted self-locking nut forming method and its device. The central force makes each locking flap of the slotted self-locking nut receive equal closing pressure, so that the closing value of each locking flap can be uniform, and the processed slotted self-locking nut has high product precision.

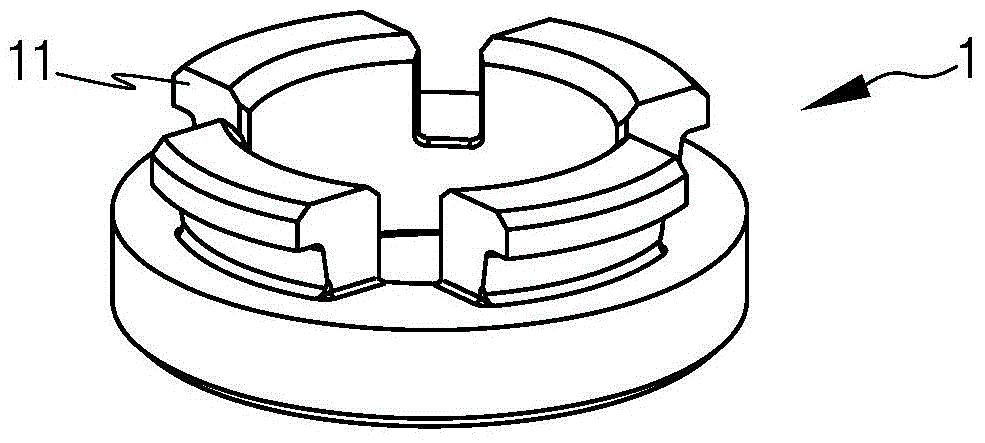

[0023] figure 1 It is a structural schematic diagram of a slotted self-locking nut; figure 2 It is a three-dimensional exploded schematic diagram of a device used in a method for forming a slotted self-locking nut according to a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com