Conduit closing-in clamp and closing-in method

A fixture and conduit technology, applied in manufacturing tools, metal processing equipment, feeding devices, etc., can solve the problems of inability to meet the design requirements of high-precision parts, out-of-tolerance parts, and inability to repair, to improve the quality and the pass rate of closing , The idea is scientific and novel, and the effect of improving the precision of closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

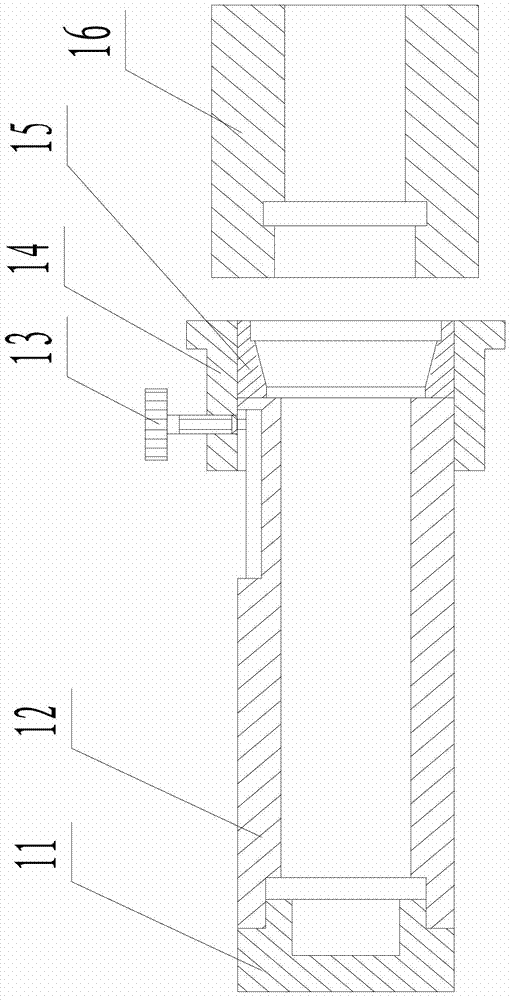

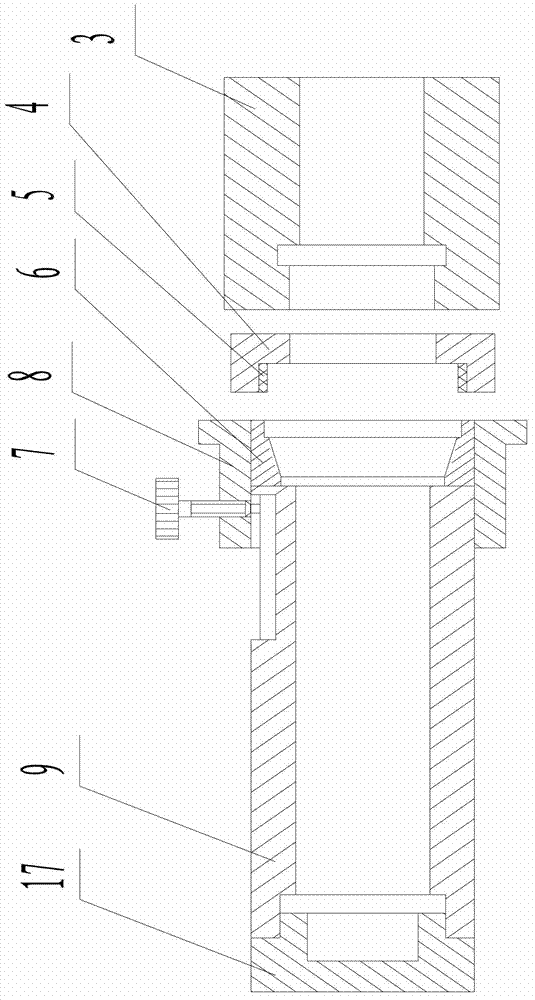

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] Taking the oil return pipe externally connected to the bearing as an example, the closing fixture and closing method of the present invention will be described in detail.

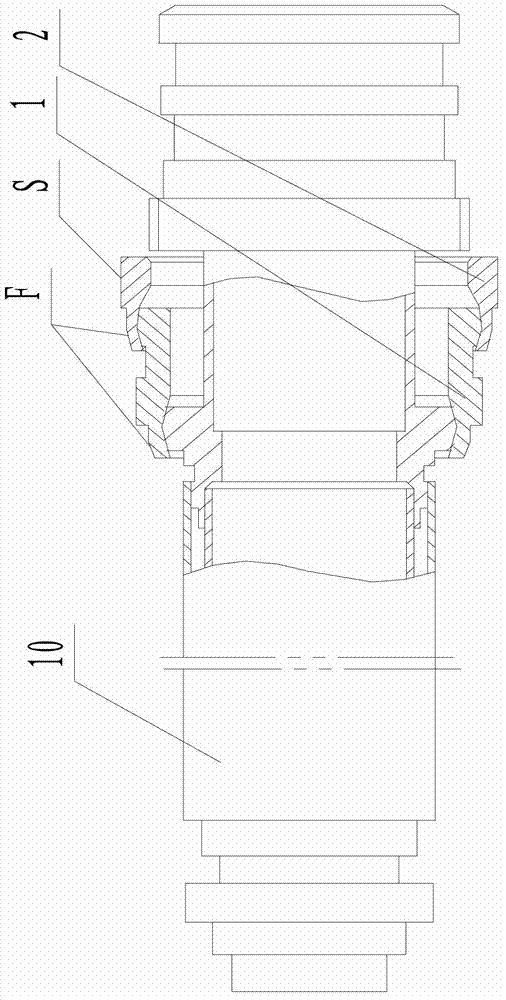

[0031] The oil return pipe externally connected to the rear bearing is composed of pipe joints and pipes through argon arc welding to form a conduit assembly 10. The combined welded conduit assembly 10 is divided into two parts to assemble the two bushings and press the ball to make it into one body. The oil return pipe is externally connected to the rear bearing. The structure is as figure 1 shown.

[0032] The outer surface of the two bushings has a silver-plated layer, and the coating is easily damaged when closing. After closing, the S dimension of the cylindrical surface of the second bushing 2 is easily deformed and out of tolerance. The cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com