Closing tool for end socket of air cylinder

A head and air cylinder technology, which is applied in the field of train air cylinder head closing tooling, can solve the problems of slow closing, no head lining mold, and large deformation of the outer diameter of the head, so as to reduce production costs and improve The effect of production efficiency and easy installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below by preferred embodiments of the present invention:

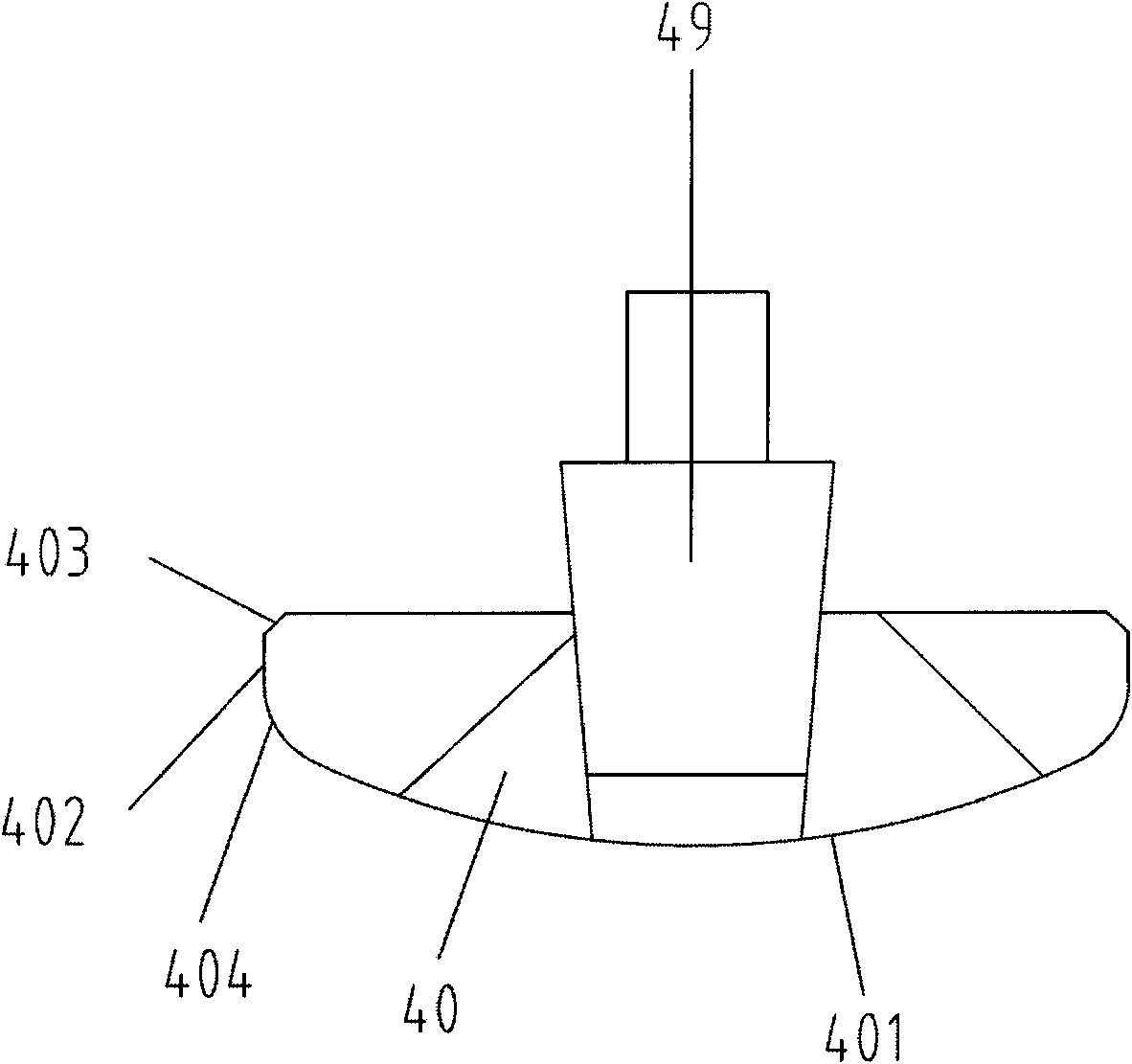

[0036] The air cylinder head closing tooling of the present invention is used for processing the head of the air cylinder in the braking structure of the train, and forms a straight edge closing adjacent to the head. The head is roughly in the shape of a cover, and after processing, it includes a partially spherical top; an annular side wall extending from the top, that is, a straight edge; and an annular closing mouth extending from the side wall with a gradually smaller diameter. In this preferred embodiment, the air cylinder is an aluminum alloy air cylinder, that is, the head is an aluminum alloy head.

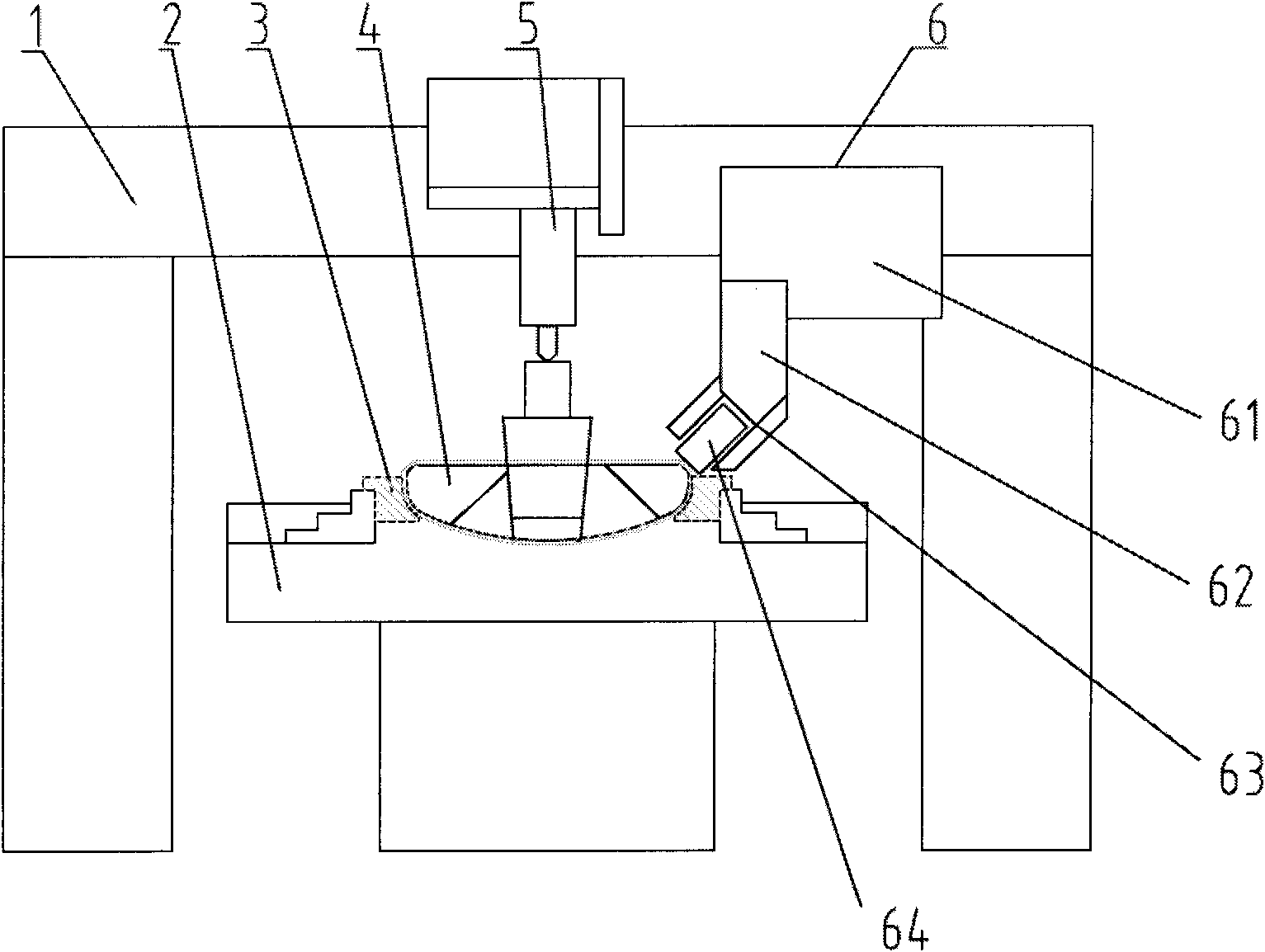

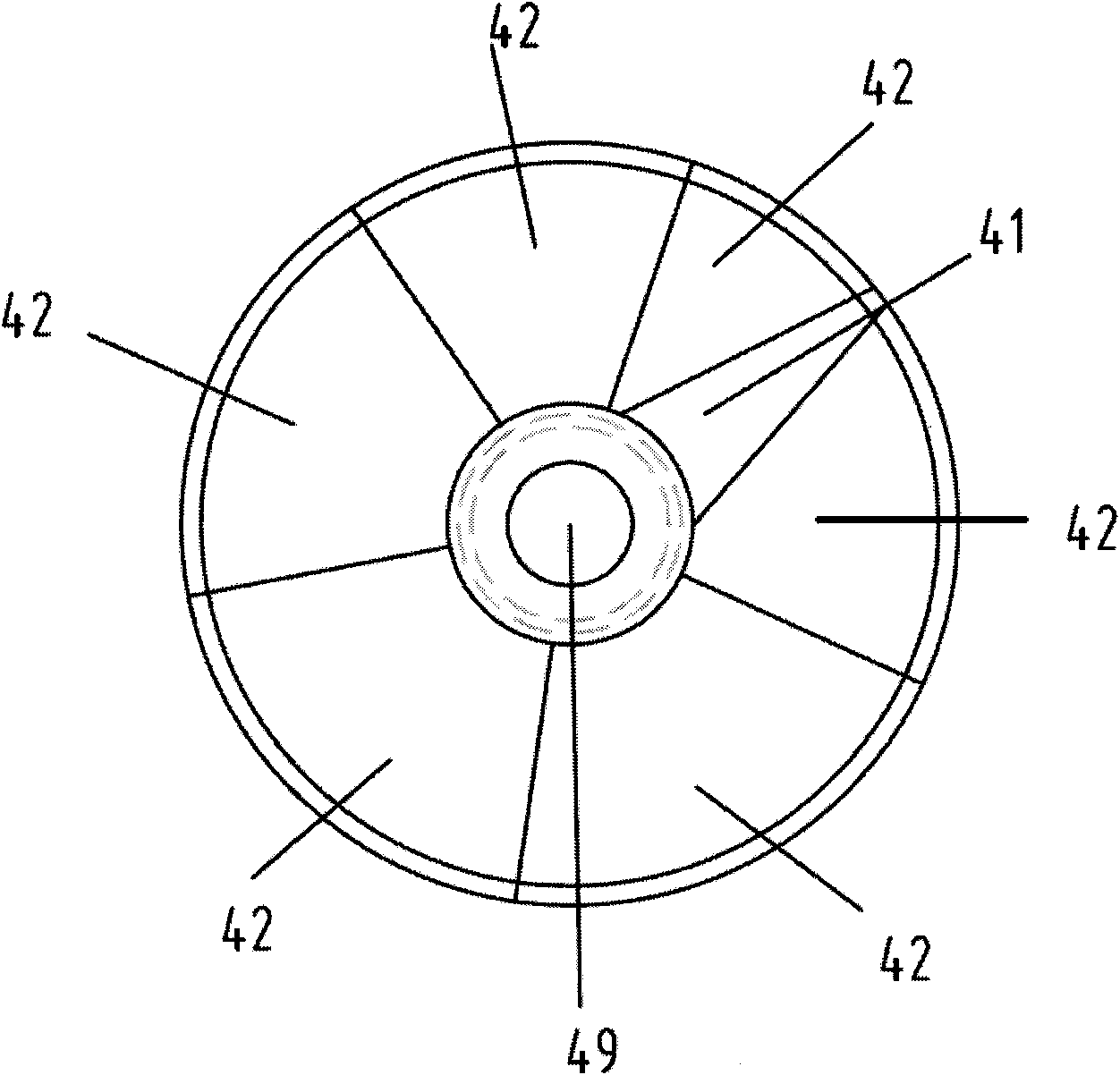

[0037] Such as figure 1 , a specific air cylinder head closing tooling of the present invention mainly includes a clamping device, a head outer lining ring 3 installed on a chuck 2, a head inner lining mold 4, and a frame 1, which are installed on the frame 1 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com