Numerical control machine tool clamp

A technology of CNC machine tools and fixtures, applied in the direction of clamping, clamping devices, manufacturing tools, etc., can solve the problems of manpower tightening and clamping force, damage to the clamped items, etc., and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

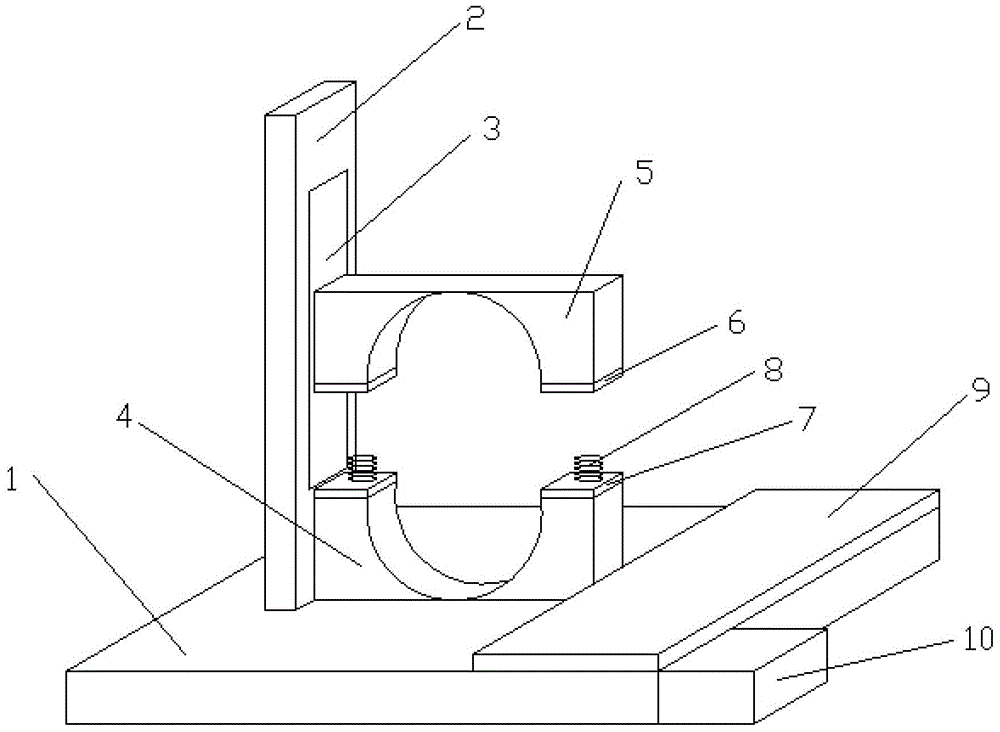

[0030] figure 1 The fixture for numerically controlled machine tool shown comprises base 1, and base 1 is provided with vertical plate 2, lower pressure plate 4, solar panel 9, storage battery 10, described vertical plate 2 slides and connects upper pressure plate 5 on one side, upper pressure plate 5 and The lower pressing plate 4 is arranged on the same axis, the two ends of the bottom of the upper pressing plate 5 are provided with electromagnets 6, the two ends of the top of the lower pressing plate 4 are provided with iron sheets 7, and the iron sheets 7 are provided with elastic parts 8. The electromagnets 6 , solar panels 9 are connected to the storage battery 10 respectively.

[0031] One side of the vertical plate 2 is provided with a chute 3 , and the upper pressing plate 5 is arranged on the chute 3 . The chute 3 is provided with several holes, and the upper pressing plate 5 is inserted into the holes by a latch so that the upper pressing plate 5 is fixed on the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com