Dust hopper on-line guiding device

An ash hopper and ash thinning technology, applied in the directions of packaging, transportation and packaging, containers, etc., can solve the problems of machine damage, the effect is not particularly good, the ash hopper is easy to accumulate dust, etc., and achieves stable operation and excellent dust drainage effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

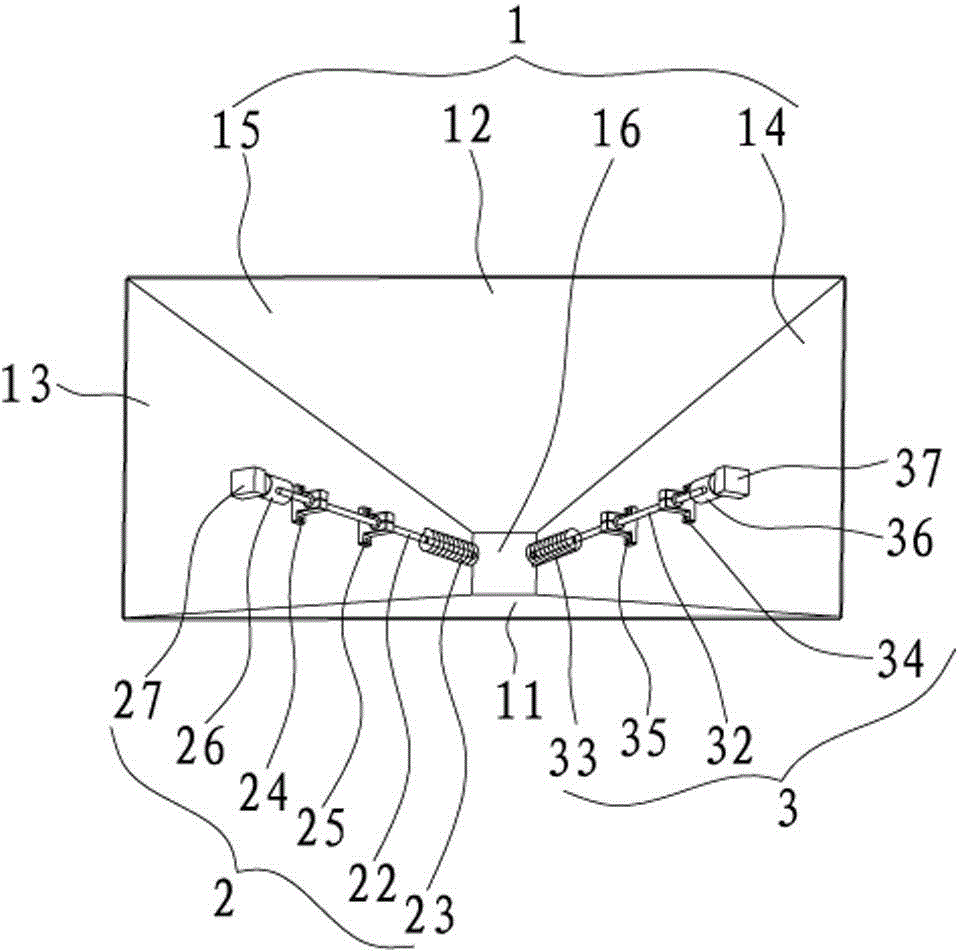

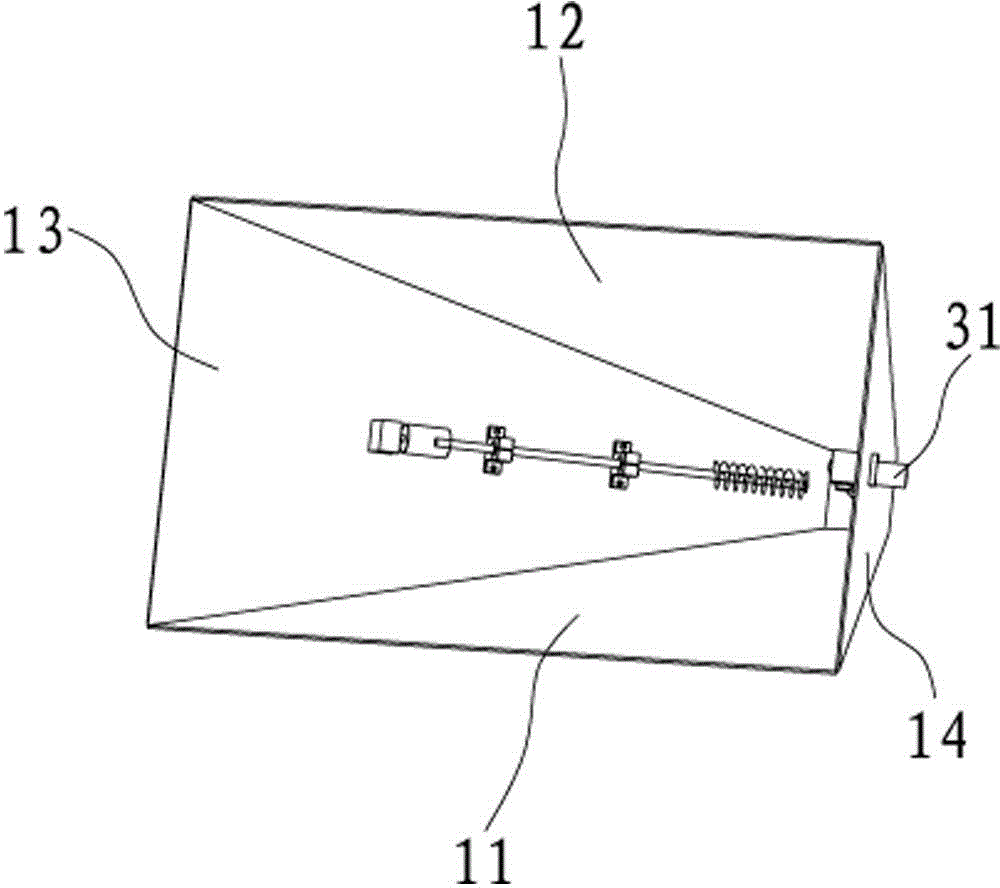

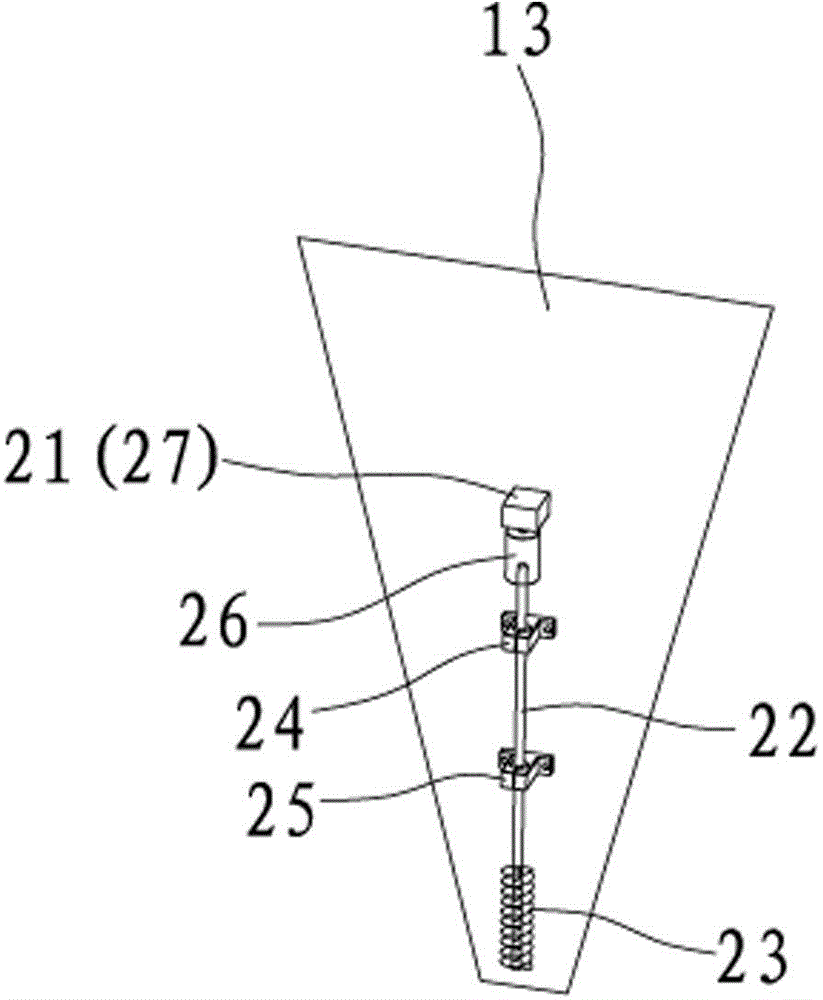

[0030] like Figure 1 to Figure 3 As shown, the present invention relates to an online dredging device for an ash hopper 1. The ash hopper 1 has an ash outlet 16. Specifically, the ash hopper 1 includes a first wide trapezoidal surface 11, a second wide trapezoidal surface 12, a first wide trapezoidal surface The four sides formed by the narrow trapezoidal surface 13 and the second narrow trapezoidal surface 14, the first wide trapezoidal surface 11 and the second wide trapezoidal surface 12 are arranged oppositely, and the first narrow trapezoidal surface 13 and the second narrow trapezoidal surface 14 are arranged oppositely , the first wide trapezoidal surface 11, the second wide trapezoidal surface 12, the first narrow trapezoidal surface 13 and the second narrow trapezoidal surface 14 form the ash inlet 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com