Steering conveying device for ceramic plates

A conveying device and ceramic plate technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of ceramic plate damage, low production efficiency, and high labor intensity, and achieve the effects of improving production efficiency, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will be further described with reference to the accompanying drawings and in conjunction with specific embodiments, so that those skilled in the art can implement it by referring to the text of the description, and the scope of protection is not limited by the embodiments of the technical solution.

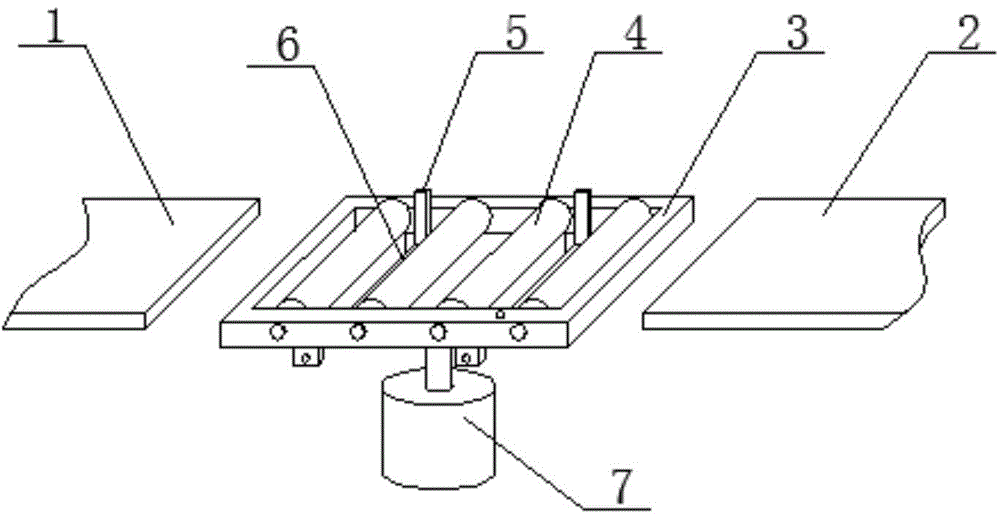

[0017] The preferred embodiment of the present invention is as follows figure 1 Shown, a kind of ceramic plate steering conveying device, wherein, it comprises: front conveying channel 1, rear conveying channel 2, bogie 3, auxiliary roller 4, push plate 5, pushing mechanism and rotating mechanism, bogie 3 is arranged on front Between the conveying channel 1 and the rear conveying channel 2, the front conveying channel transports the ceramic plate to the bogie 3, and after the ceramic plate is turned by the bogie 3, it is transported to the rear conveying channel 2, thereby realizing the steering of the ceramic plate delivery. The bogie 3 is driven to rotate b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com