Blanking device for synthesis hollow coated glass

A coated glass, hollow technology, used in transportation and packaging, conveyor objects, furnaces, etc., can solve problems such as weight increase, glass substrate clip film misalignment, drop, etc., to reduce defects, improve production efficiency, and ensure product quality. The effect of specification quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

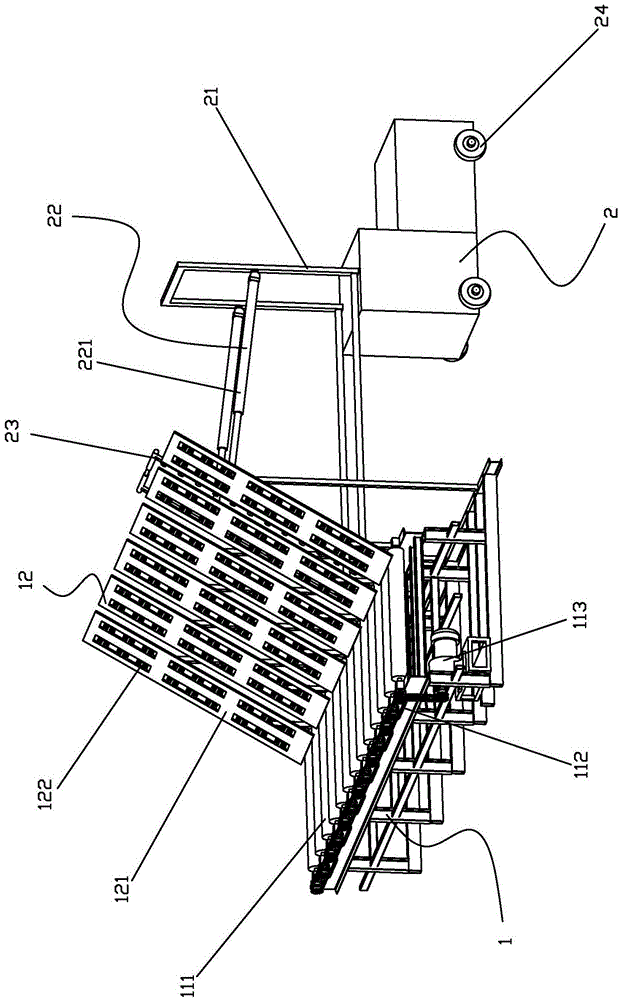

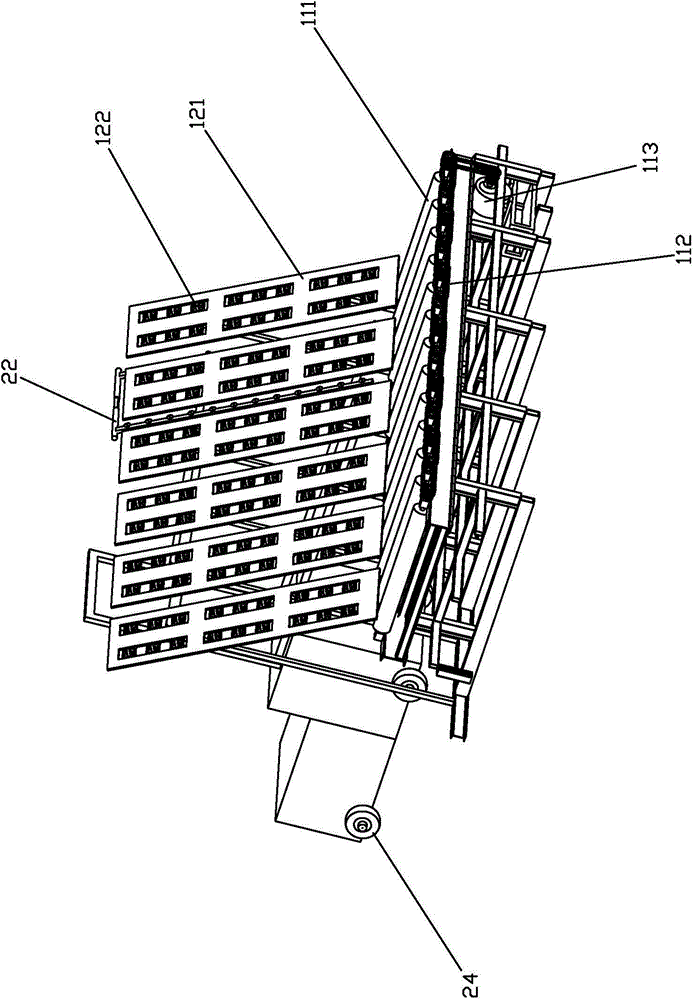

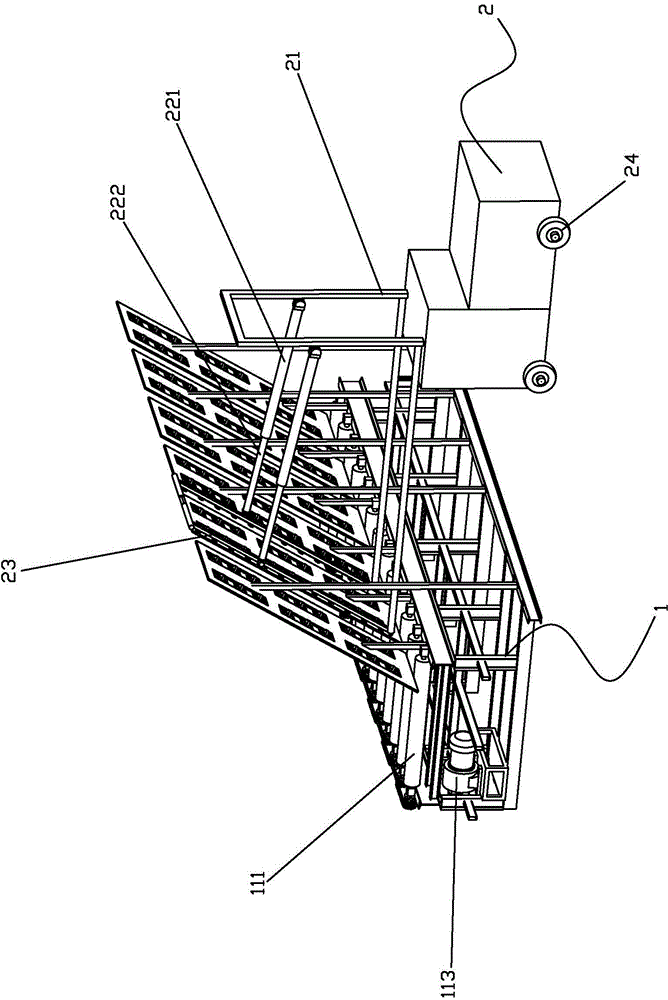

[0024] A blanking device for synthesizing hollow coated glass, comprising a frame 1 on which a conveying device 11 for supporting and driving the glass to move horizontally and a back plate frame for assisting the conveying device 11 to transfer the glass are erected on the frame 1 12. One side of the back plate frame 12 is provided with a unloading device 2 that can absorb and synthesize hollow coated glass and can transfer the hollow coated glass along the side of the back plate frame 12 and turn it over and place it on the glass transfer device. . The unloading device can absorb the laminated sheet of insulating glass from the lower part, turn it over to hoist it, and remove the hollow glass from the side of the backboard frame, that is, along the transfer direction perpendicular to the backboard frame, or along the transfer direction of the backboard frame. The coated glass is removed onto a glass transfer device.

[0025] One side of the back plate frame 12 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com