Four-wheel drive wire feeding mechanism

A four-wheel drive, transmission mechanism technology, applied in the transportation of filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of affecting the terminal crimping process, low work efficiency, weak transmission power, etc., to improve the overall The effect of work efficiency, good wire feeding stability and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

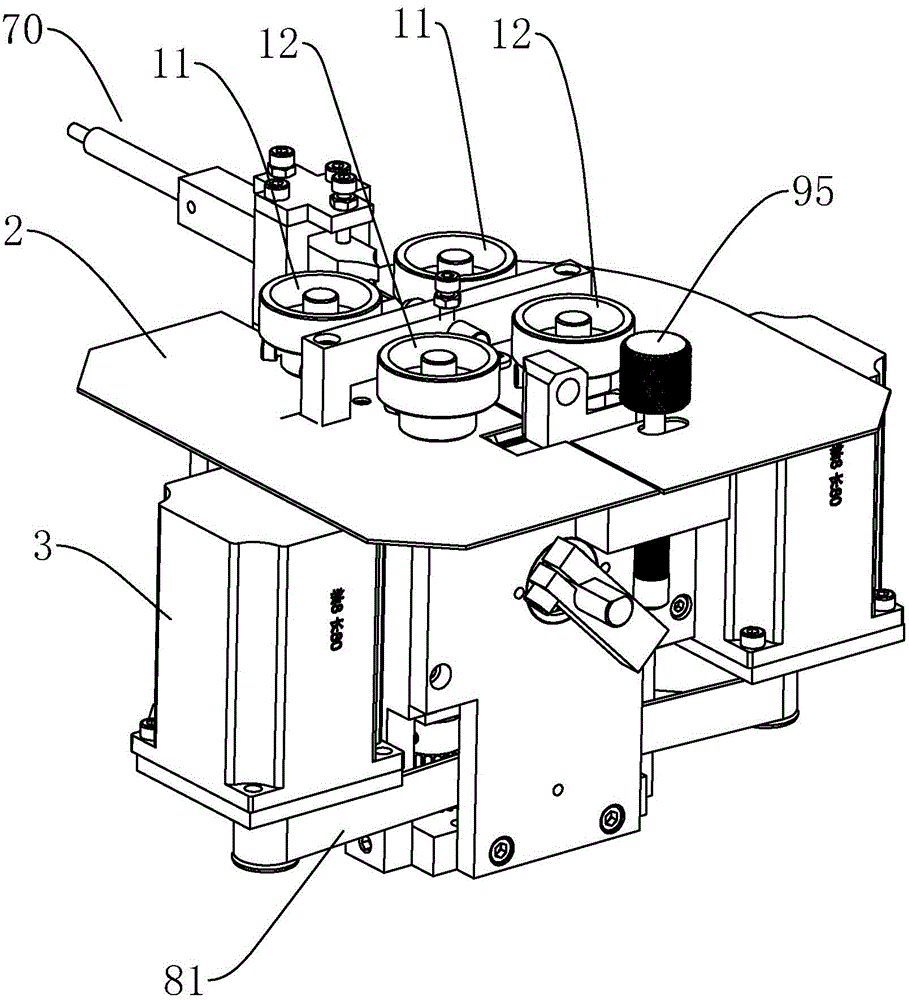

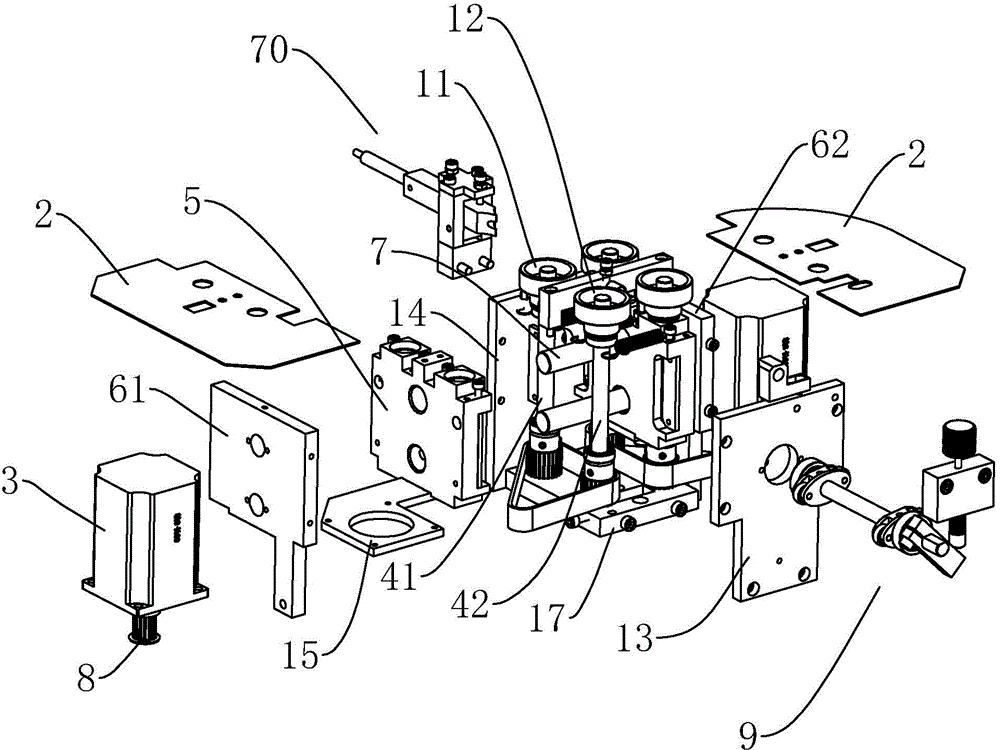

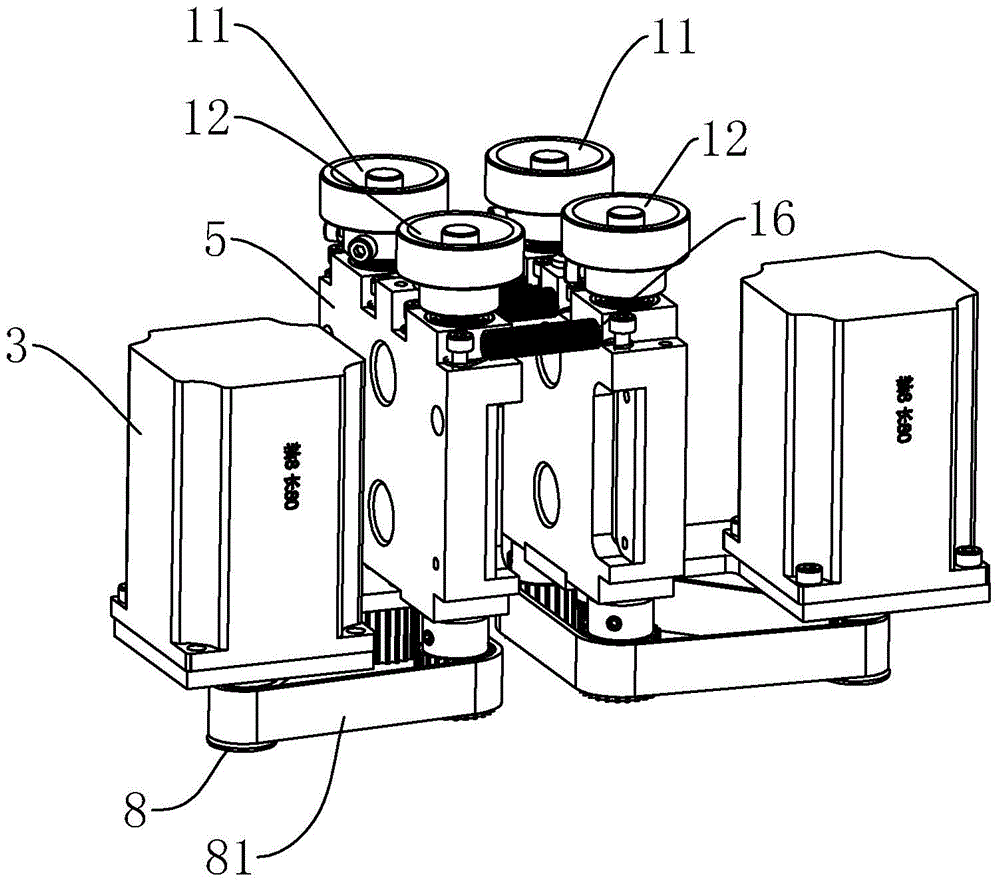

[0024] refer to Figure 1 to Figure 7 , Figure 1 to Figure 7 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, a four-wheel drive wire feeding mechanism includes a frame, a cover plate 2 arranged on the frame, and two sets of wire feeding wheel mechanisms respectively arranged on both sides of the frame , the frame consists of a base plate 17, a front panel 14, a rear panel 13, a left vertical plate 61, a right vertical plate 62, and the wire feeding wheel mechanism includes a motor 3, a first transmission shaft 41, a second transmission shaft 42, a first Wire feeding wheel 11, the second wire feeding wheel 12, the motor 3 is arranged downwards and is connected to the lower ends of the first transmission shaft 41 and the second transmission shaft 42 through a transmission mechanism such as a belt transmission mechanism, a gear transmission mechanism, etc. It can drive the first transmission shaft 41 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com