Multilayer fabricated concrete wallboard structure system

A technology of concrete wall and slab structure, which is applied in the direction of walls, building components, building structures, etc., and can solve the problems of weakening the advantage of fast construction speed of prefabricated concrete structure system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

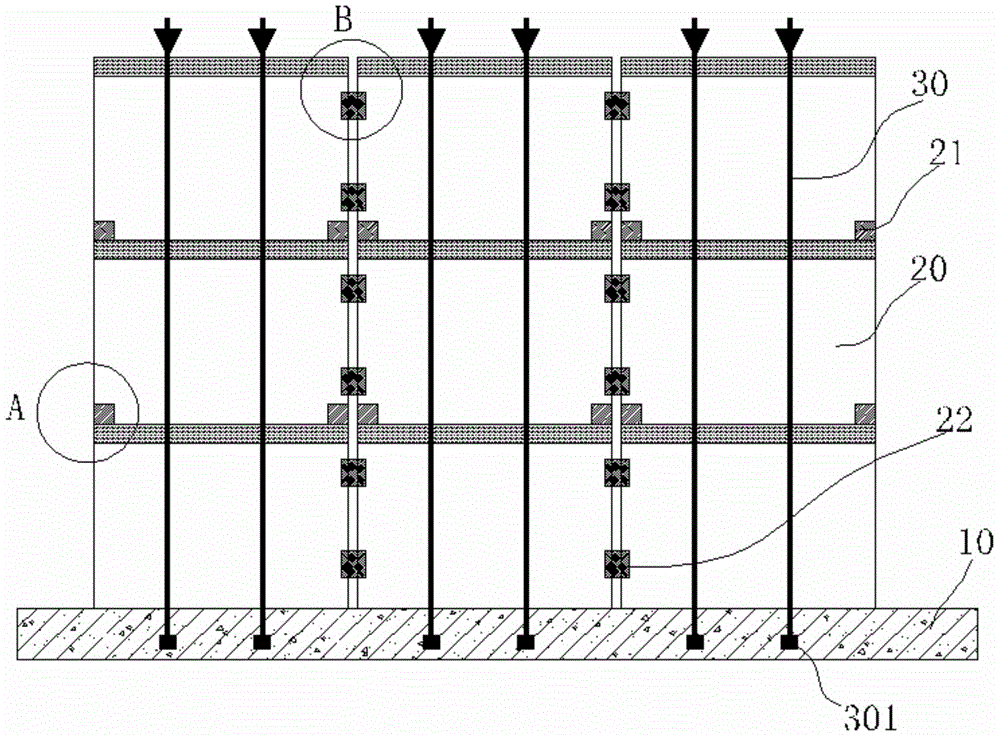

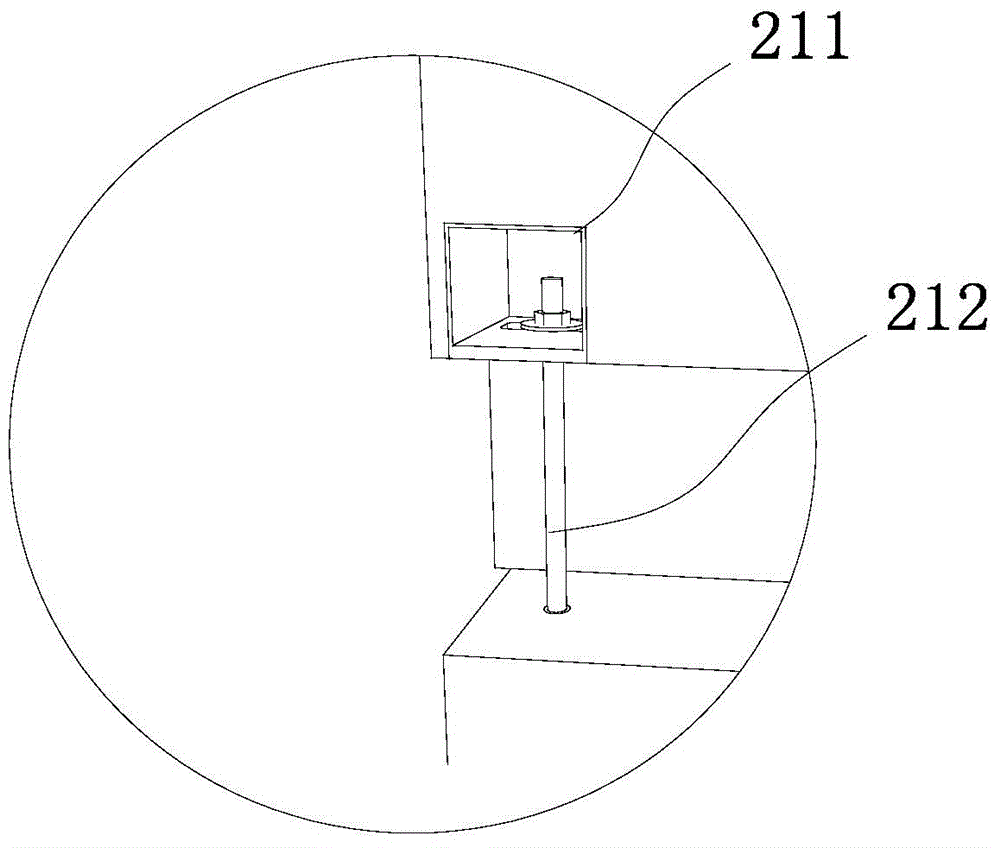

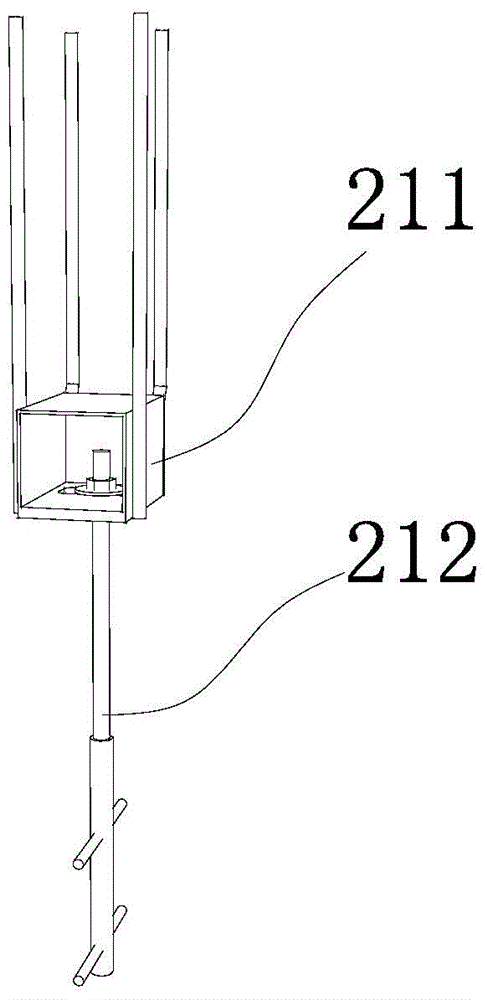

[0037] Embodiments of the present invention are as follows, see Figure 1 to Figure 5 , a multi-layer fabricated concrete wall panel structure system, comprising a foundation 10, a prefabricated wall panel 20, and unbonded prestressed tendons 30, the prefabricated wall panel 20 is arranged on the foundation 10, at least two prefabricated wall panels 20 Put together vertically, the unbonded prestressed tendons 30 connect the at least two prefabricated wall panels 20 and the foundation 10 into a whole, and the foundation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com