Needle gauge processing precision detection apparatus

A technology of processing accuracy and detection device, applied in the direction of measuring device, testing material hardness, instrument, etc., can solve the problem of low detection efficiency, and achieve the effect of solving the low detection efficiency and avoiding repeated detection.

Inactive Publication Date: 2015-10-07

CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] The invention provides a needle gauge processing precision detection device, which solves the technical problem of low detection efficiency in the existing needle gauge precision detection, and realizes the technical effect of high needle gauge processing precision detection efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

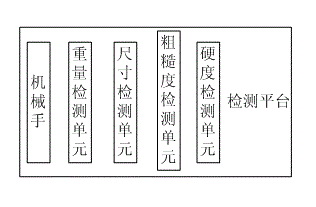

[0028] In Embodiment 1, a needle gauge processing accuracy detection device is provided, please refer to figure 1 , the device includes:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a needle gauge processing precision detection apparatus including a detection platform, a weight detection unit, a dimension detection unit, a roughness detection unit, and a hardness detection unit, the detection platform detects a needle gauge to be detected and is provided with a manipulator which is used for carrying the needle gauge to be detected, the weight detection unit detects the weight of the needle gauge to be detected, the dimension detection unit detects the dimension information of the needle gauge to be detected, the roughness detection unit detects the surface roughness of the needle gauge to be detected, and the hardness detection unit detects the hardness of the needle gauge to be detected. The needle gauge processing precision detection apparatus is high in needle gauge processing precision detection efficiency.

Description

technical field [0001] The invention relates to the field of needle gauge price manufacturing, in particular to a needle gauge processing accuracy detection device. Background technique [0002] Needle gauges are round rods with specific dimensions that are made of white steel, tool steel, ceramics, tungsten steel bearing steel, etc. or other materials. [0003] Needle gauges are suitable for the measurement of hole diameter, hole distance, and small diameter of internal thread in mechanical and electronic processing, especially for the measurement of bending groove width and mold size. [0004] It is used to check the position, measure the size of the hole, check the distance between two holes, and can also be used as a go-no-go gauge and measure the depth of the hole. It is a necessary inspection tool for the standardized inspection of the hole. Widely used in various high-tech fields such as electronic boards, circuit boards, molds, and precision machinery manufacturing....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B21/30G01B21/02G01B21/10G01N3/40

CPCG01D21/02

Inventor 吴光武

Owner CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com