Ultrasonic cleaning device for cables

A cleaning device and ultrasonic technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of low scrubbing efficiency, unable to remove stains and impurities, poor cleaning effect, etc. Improve effect, smooth flow, avoid distraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

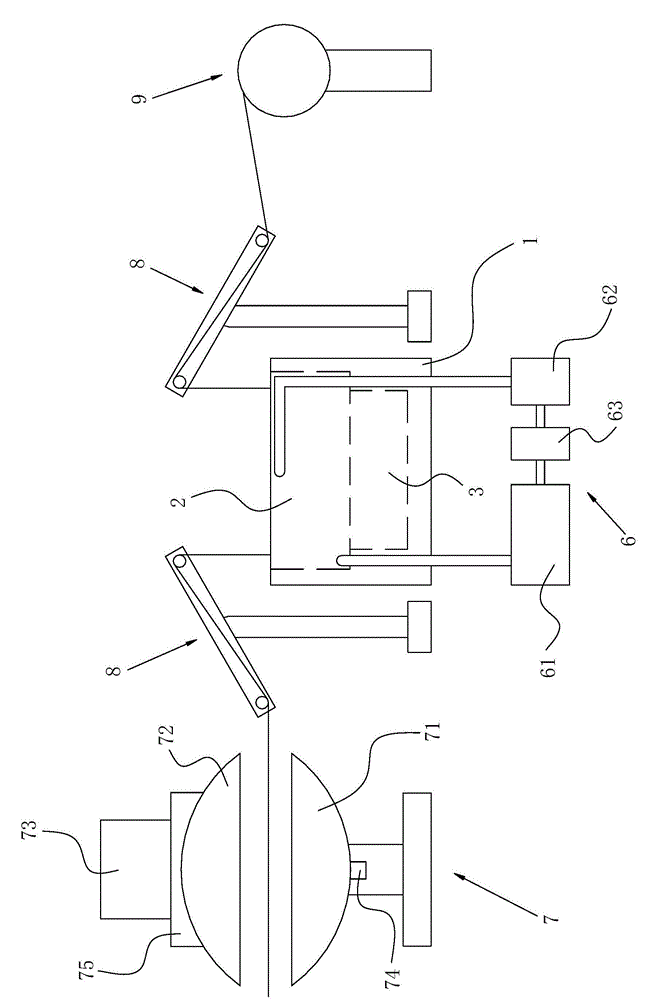

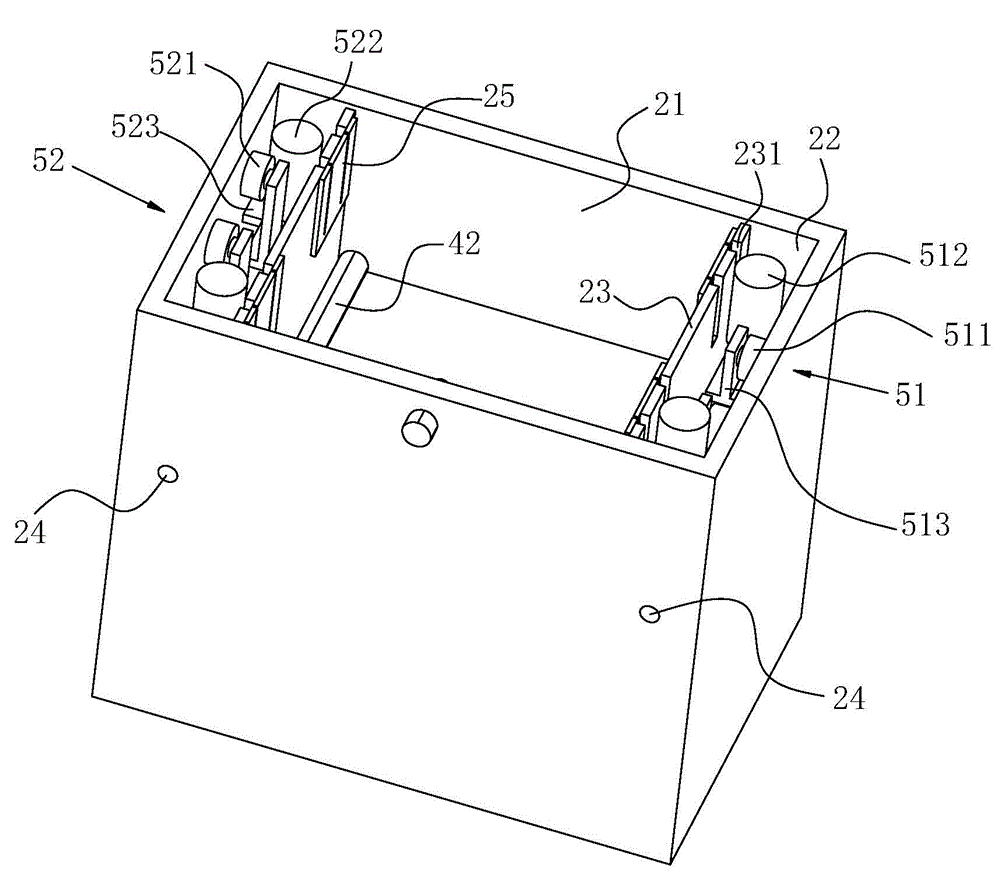

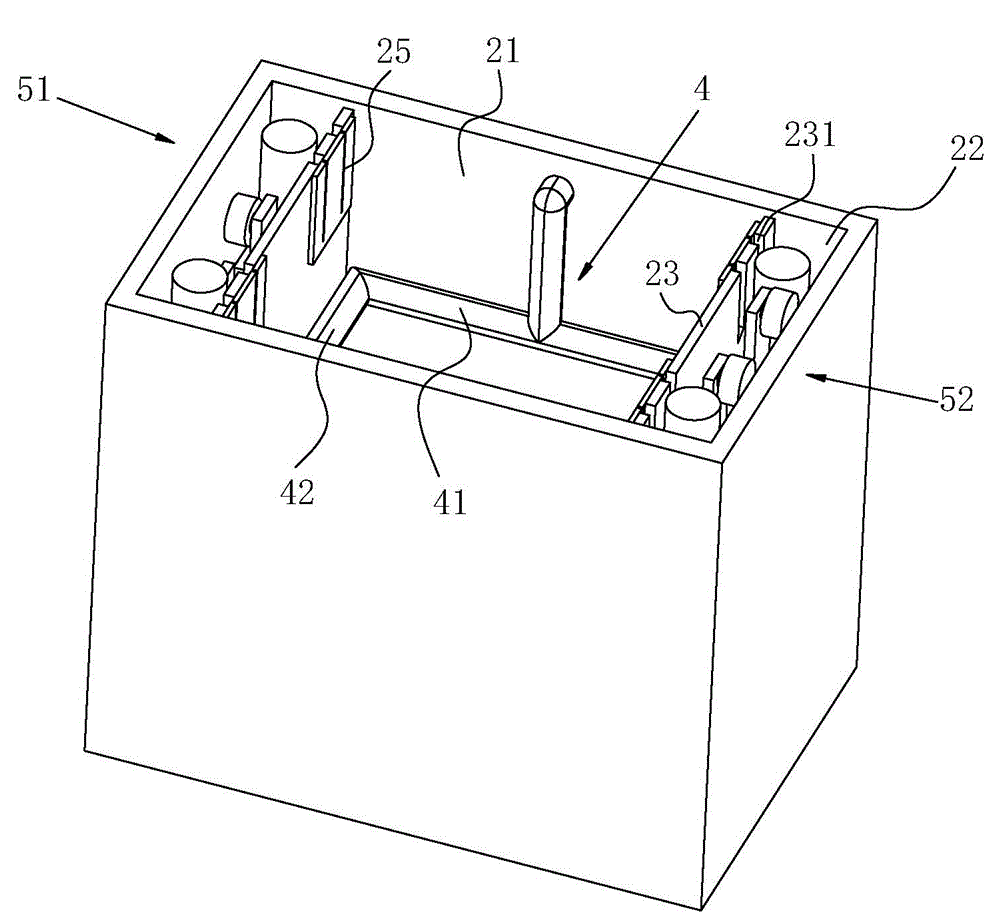

[0056] Such as Figure 1~4 As shown, in this embodiment, a cable ultrasonic cleaning device includes a cleaning frame 1 and a cleaning box 2 arranged on the cleaning frame 1, and the cleaning frame 1 is located on the cleaning box 2 is provided with an ultrasonic generator 3 for driving the cleaning liquid to vibrate. The cleaning tank 2 includes a main cleaning tank 21 and auxiliary cleaning tanks 22 located on both sides of the main cleaning tank 21. The main cleaning tank 21 is filled with For the cleaning solution, the main cleaning tank 21 is provided with a circulating water inlet pipe 4, and the surface of the circulating water inlet pipe 4 is provided with a number of water inlet holes, and the auxiliary cleaning tank 22 is provided with at least one group for making the line The cable wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com