Integrated punching machine for keel sheet metal forming

A technology of metal sheets and die machines, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of simple process, time-consuming and labor-intensive, multi-manpower transportation, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in conjunction with specific embodiment now. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

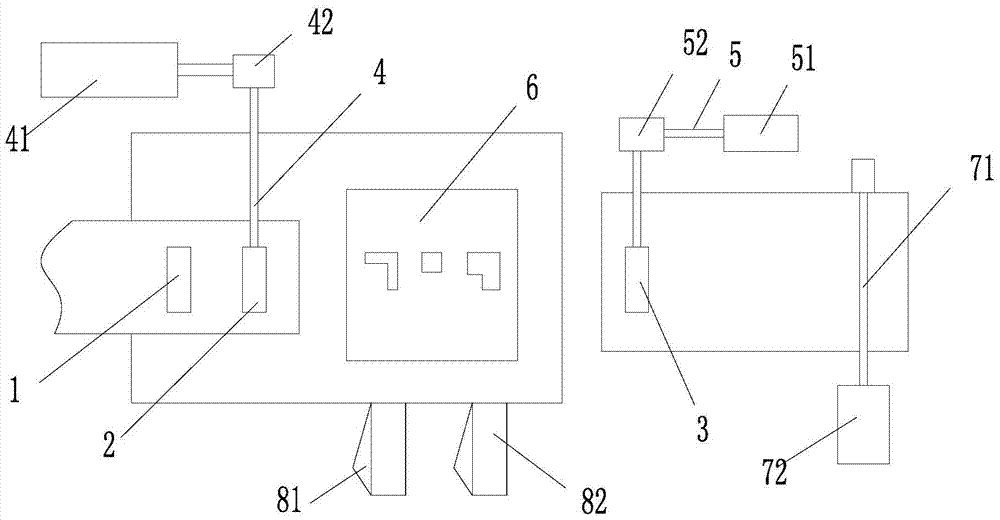

[0022] Such as figure 1 , figure 2 As shown, an integrated punching machine for forming keel metal sheets, which sequentially includes a front conveying area, a die area, a rear conveying area, and a rear coiling area; the die area includes a lower die 6, which corresponds to the lower die 6 upper mold.

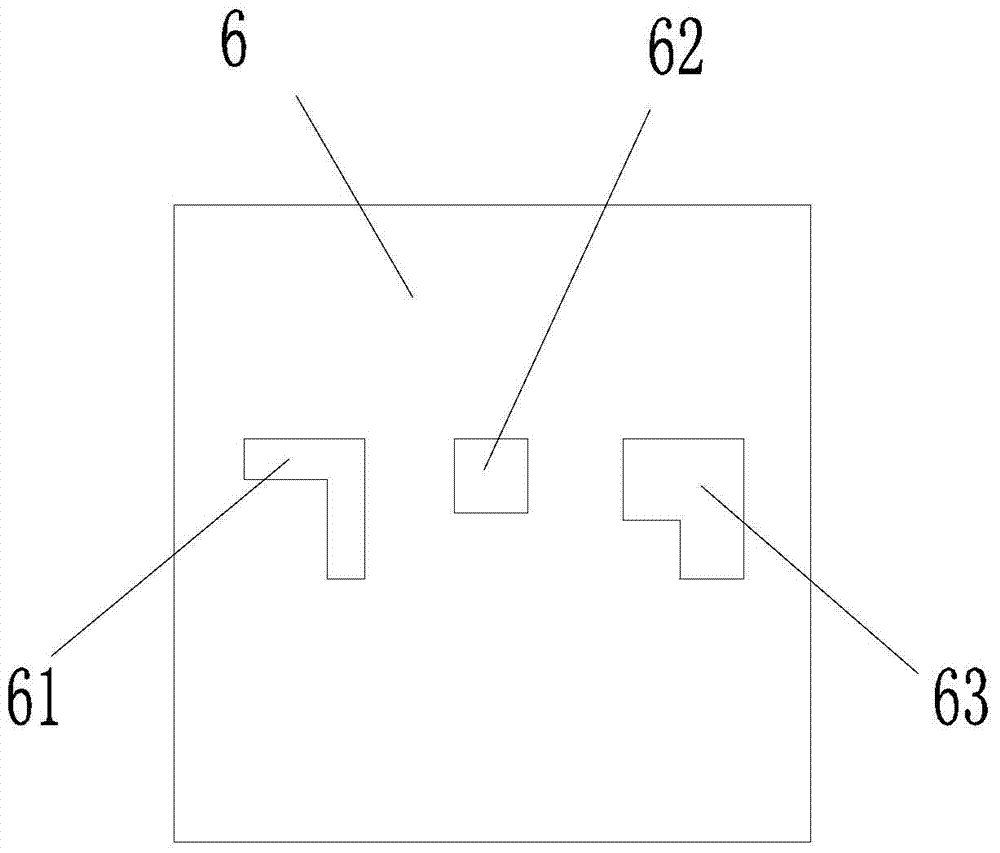

[0023] The lower die 6 is provided with a waste material punching area 61, a forming area 62 and a finished product punching area 63. The waste material punching area 61, the forming area 62 and the finished product punching area 63 are sequentially arranged on the lower die 6 along the moving direction of the raw material. Zone 61 has scrap die cut through holes, forming zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com