Injection molding machine provided with elevation type signal lamp

A technology for injection molding machines and signal lamps, which is applied to signal devices, visible signal devices, household appliances, etc., can solve problems that are not suitable for the observation and confirmation of the operation status of injection molding machines, and achieve the effect of avoiding object interference and ensuring height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

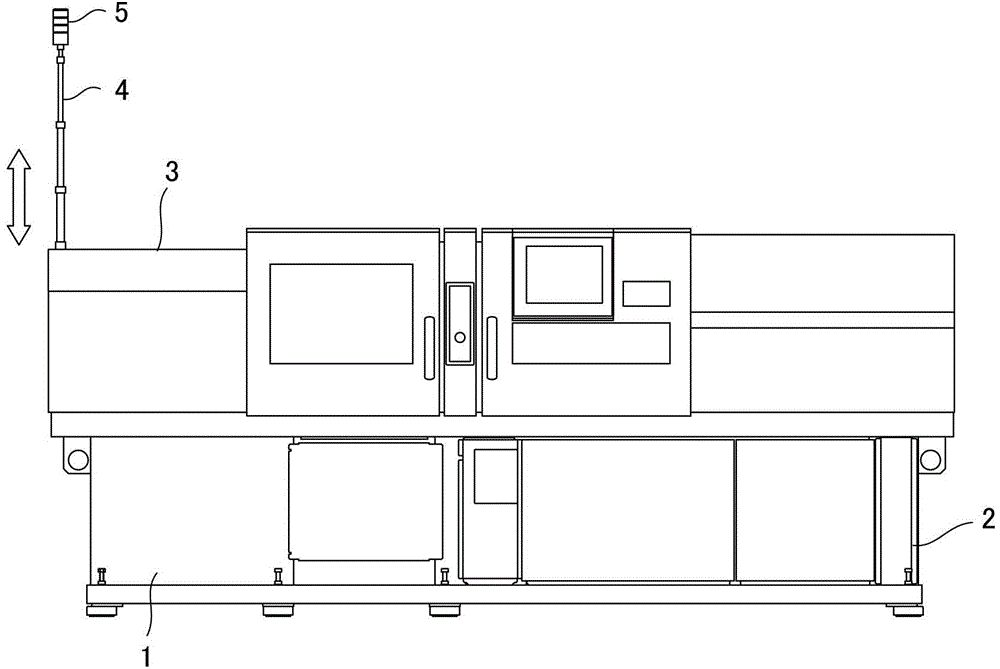

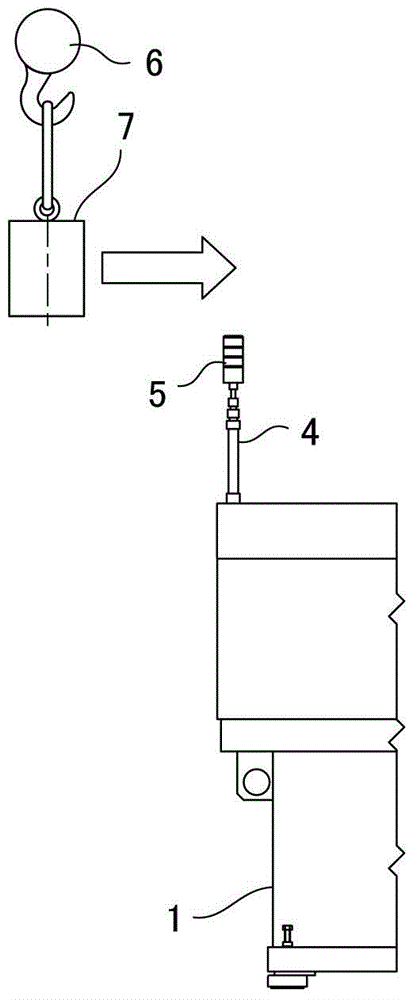

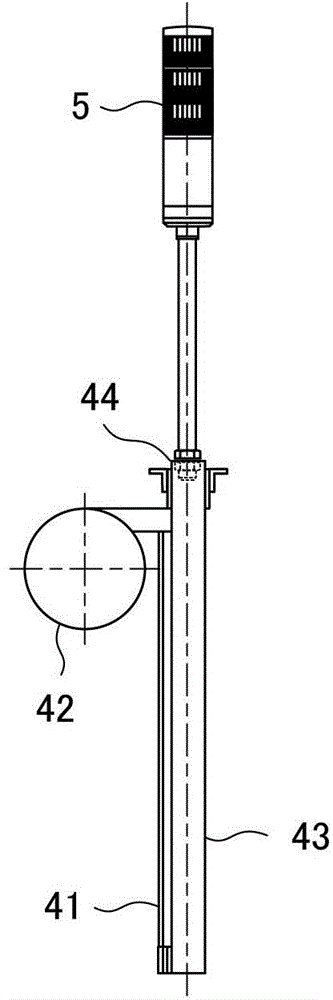

[0025] Figure 1A as well as Figure 1B It is a figure which shows the injection molding machine equipped with the signal lamp. Figure 1A It is a figure which looked at the injection molding machine from the front, and shows the state which raises the signal lamp 5. Figure 1B It is a view of the injection molding machine viewed from the side, and shows a state in which the signal lamp 5 is lowered.

[0026] The injection molding machine 1 includes an injection unit and a mold clamping unit on a machine base 2 . The injection molding machine 1 is controlled by a control device not shown. The injection part and the mold clamping part are covered with a cover 3 . On the upper surface of the cover 3 of the injection molding machine 1 , a lifting unit 4 including a signal lamp 5 is attached.

[0027] The lifting unit 4 can be detachably or fixedly attached to the cover 3 of the injection molding machine 1 . The elevating unit 4 can manually or automatically elevate the signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com