Hand injury prevention device for inner tube splicer

A joint machine and anti-pinching technology, which is applied to other household appliances, household appliances, applications, etc., can solve problems affecting factory production efficiency, pinch injuries, and the safety of operators, achieving fast and efficient installation, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with specific drawings and embodiments.

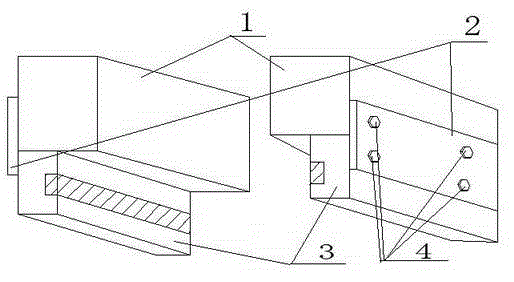

[0009] Such as figure 1 As shown: the present invention is mainly composed of an inner tube joint machine workbench 1, a fixed plate 2, a safety grating 3, and a bolt 4; Bolts 4 are fixed on both sides of the workbench 1 of the inner tube jointing machine.

[0010] During specific application, the operator fixes the rubber inner tube on the inner tube workbench 1, then starts the machine, and the inner tube joint machine workbench 1 closes to the middle to complete the joint. When the operator's hand or other objects are placed between the worktables 1 of the inner tube splicing machine, the light sensing between the safety gratings 3 will be blocked, and the electrical control module will automatically cut off the power supply until there is no obstruction between the safety gratings 3 Only when the machine is powered on can it continue to work, which effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com