Laminated plastic woven bag pick-up machine

A film plastic and bag machine technology, which is applied in container manufacturing machinery, paper/cardboard containers, box manufacturing operations, etc., can solve the problems of high labor intensity and low work efficiency, and achieve the effect of improving production efficiency and improving enterprise economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiment is further described in detail below in conjunction with accompanying drawing:

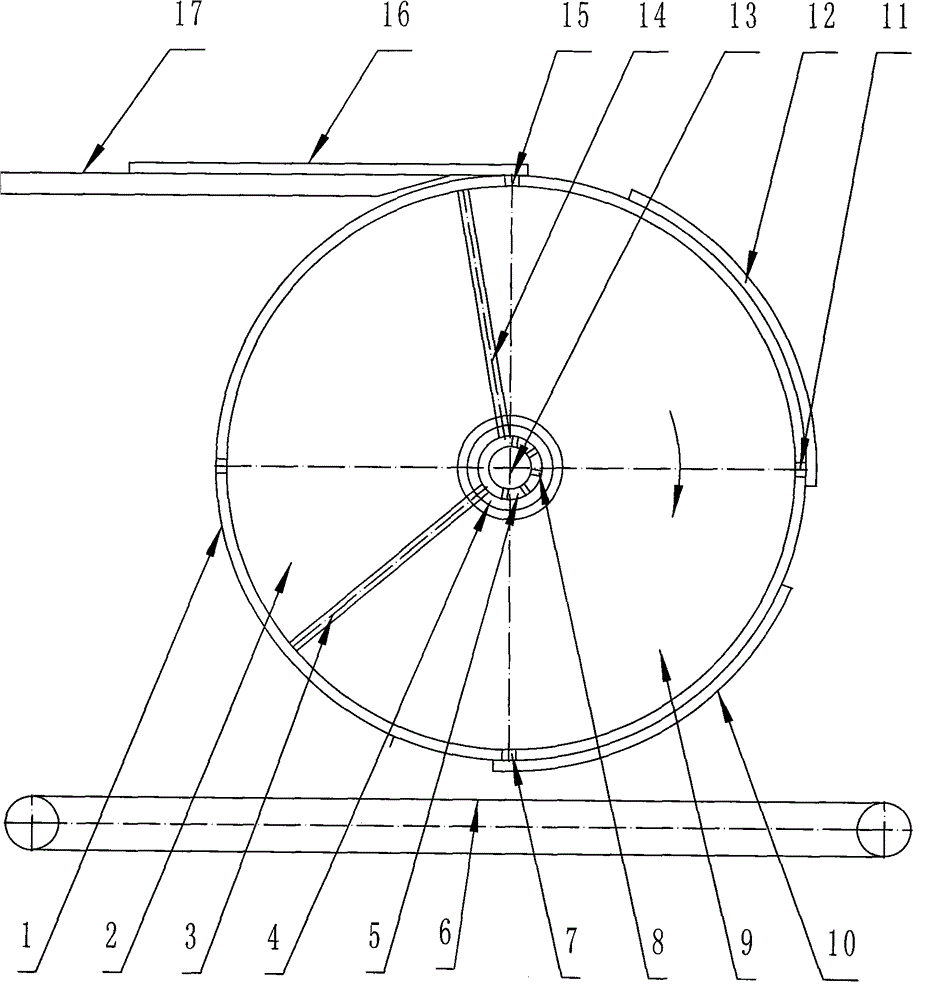

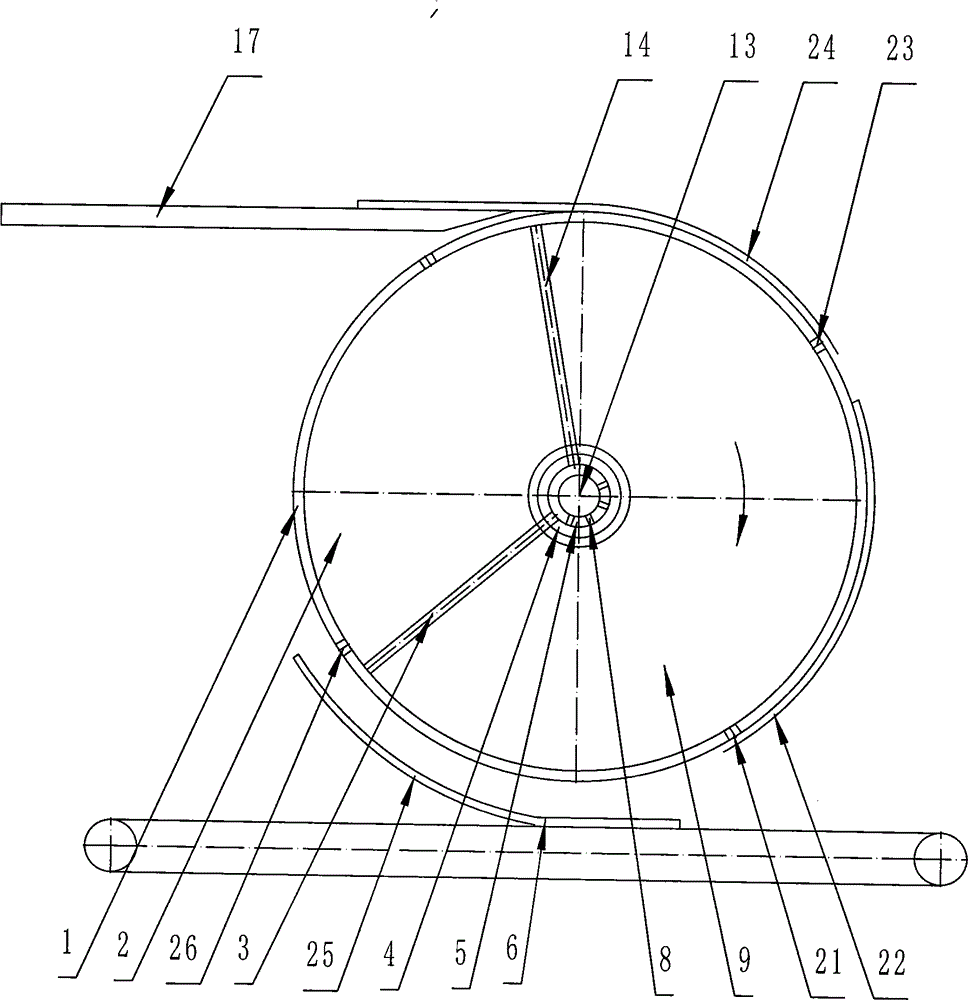

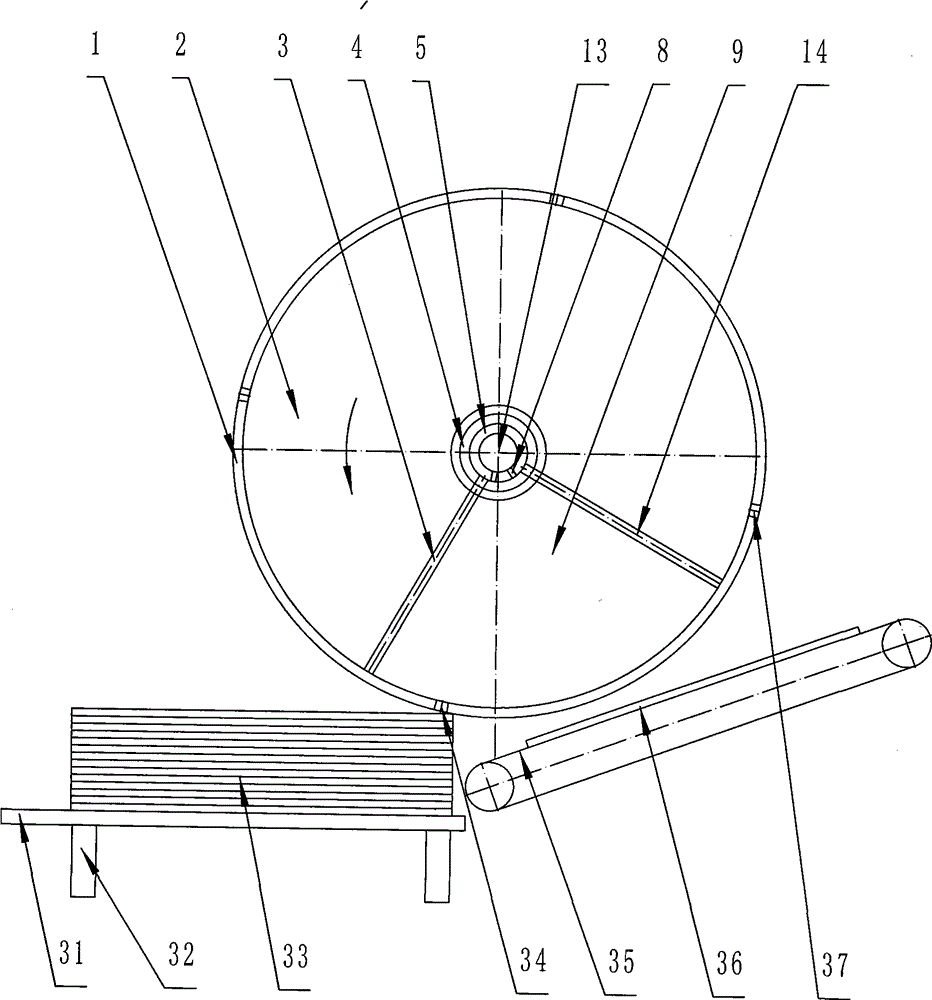

[0012] refer to figure 1 : 1-drum, 2-room A, 3-partition A, 4-bearing, 5-spindle, 6-conveyor belt, 7-the first set of radial holes, 8-wall holes, 9-room B, 10 -The first compound film plastic woven bag, 11-the second group of radial holes, 12-the second compound film plastic woven bag, 13-axis hole, 14-partition B, 15-the third group of radial Hole, 16-the third compound film plastic woven bag piece, 17-bag bearing device, this compound film plastic woven bag picking machine includes drum 1, partition A3, bearing 4, main shaft 5, conveyor belt 6, The partition B14 and the bag-bearing device 17, the main shaft 5 is fastened on the fixed frame, the drum 1 is installed on the main shaft 5 through the bearing 4, and can rotate around the main shaft 5, and the partition A3 and the partition B14 connect the drum 1 The inner space is divided into A room 2 and B room 9, the partition A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com