Cloth extraction goods shelf

A shelf and fabric technology, applied in transportation, packaging, storage devices, etc., can solve the problems of waste of manpower, low efficiency, and easy to cause safety problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

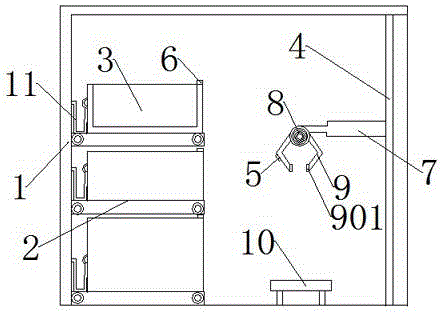

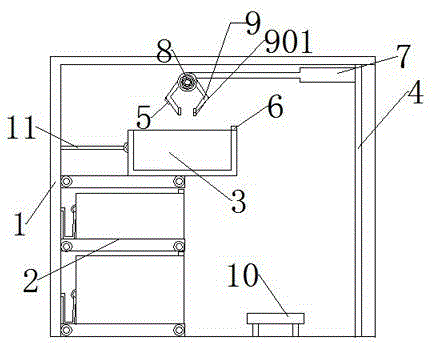

[0020] The cloth extraction shelf 1 includes: a shelf 1, a conveyor 2 on the shelf 1, a storage box 3 on the conveyor 2, a vertical moving part next to the shelf 1, and a mechanical gripper connected to the vertical moving part. Hand, as for the sensor on the mechanical gripper, as for the identification part corresponding to the sensor on the storage box 3, it is connected to the controller of the conveyor 2, the vertical moving part, and the mechanical gripper. The conveyor 2 includes: a conveyor belt placed on the shelf 1, as for the drive shaft at both ends of the conveyor belt, the drive shaft is driven to rotate and is connected to the motor of the above-mentioned controller. As a preference, the vertical moving part is the guide rail 4, the sensor is the RFID reader 5, and the identification part is the RFID tag 6. The controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com