Dismantling prevention method for tower crane operating state management and tracking controller

A technology for tracking the controller and operating status, applied in cranes, transportation and packaging, load hoisting components, etc., can solve the problems of not returning in time, unable to control the leased party, etc., to achieve ingenious ideas, great practical value, prevention Good effect of dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

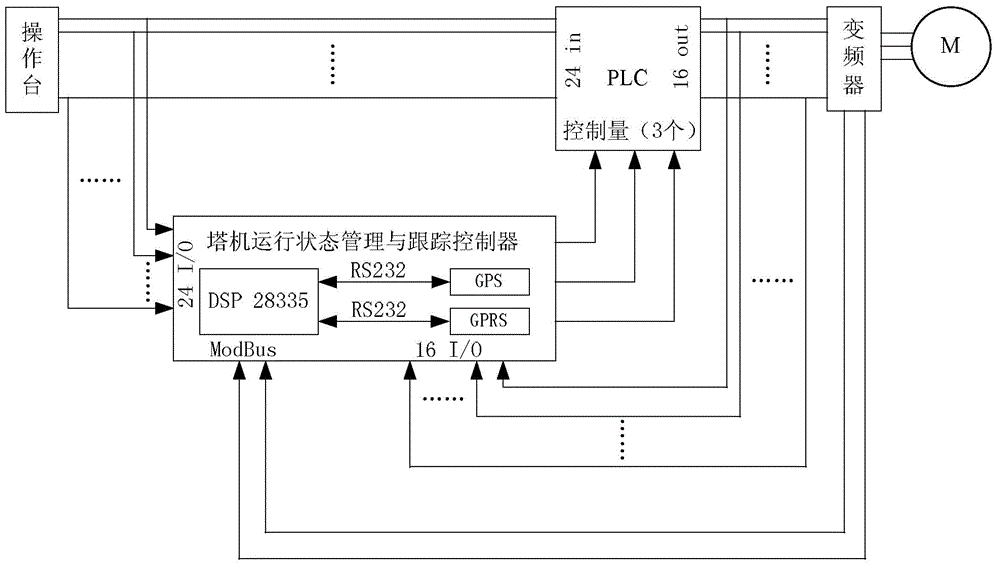

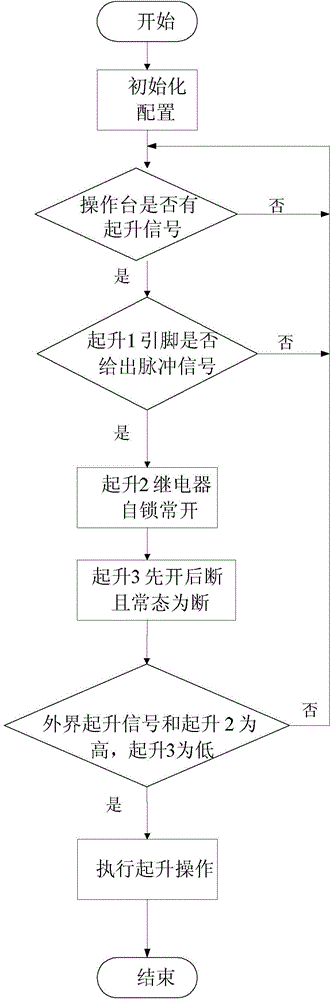

[0018] Specific implementation mode one: the following combination figure 1 and figure 2 Describe this embodiment, the anti-disassembly method of the tower crane operation state management and tracking controller described in this embodiment, the anti-disassembly method is realized by the internal logic of the tower crane controller PLC, the anti-disassembly method receives the management and tracking The lifting control signal sent by the controller starts;

[0019] Connect the lifting control signal pin of the DSP of the management and tracking controller to the lifting control signal interface of the tower crane controller PLC. After the management and tracking controller receives the lifting control signal Qs sent by the tower crane operating platform, The hoisting control signal pin of the DSP generates the hoisting control pulse signal Qs1, the hoisting control pulse signal Qs1 is active at high level, after the hoisting control signal interface of the tower crane cont...

specific Embodiment approach 2

[0025] Specific implementation mode two: the following combination figure 1 and figure 2 This embodiment is described. This embodiment further describes the first embodiment, and the continuation of the predetermined period is realized by timing of a timer.

[0026] Instructions for anti-disassembly of tower crane operation state management and tracking controller:

[0027] The usual operating states of tower cranes are three types: lifting, luffing and slewing, and each type of operation has a gear limit, and they all gradually rise from lower gears to higher gears. After the first gear is restricted, the tower crane will not be able to operate, and the present invention is designed based on this principle.

[0028] First, select three IO pins in the DSP of the tower crane operation status management and tracking controller to connect with the interfaces of the hoisting, turning, and amplitude input signals of the tower crane controller PLC respectively. The three IO pins ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com