Glass automatic processing equipment

A technology for automatic glass processing, applied in glass manufacturing equipment, glass molding, glass reshaping, etc., can solve the problems of high processing cost of single cup, uneven thickness of cup wall, low production efficiency, etc., to reduce processing Probability of occurrence of defects, standardization of work flow, and effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

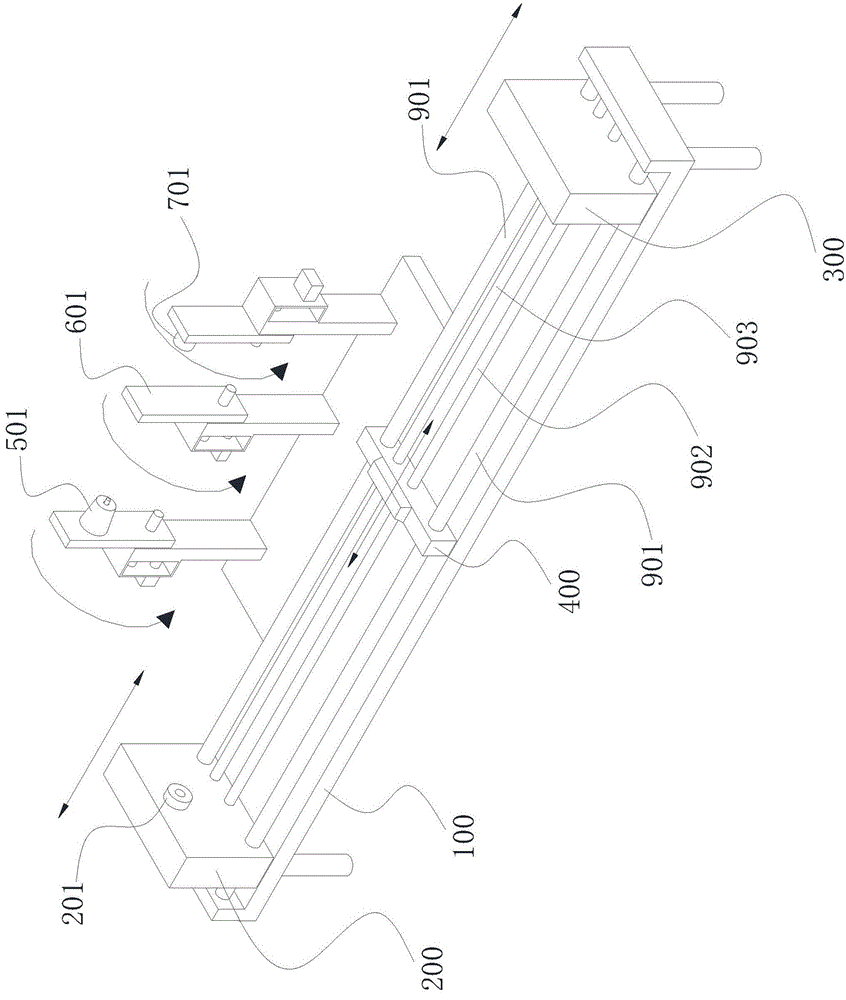

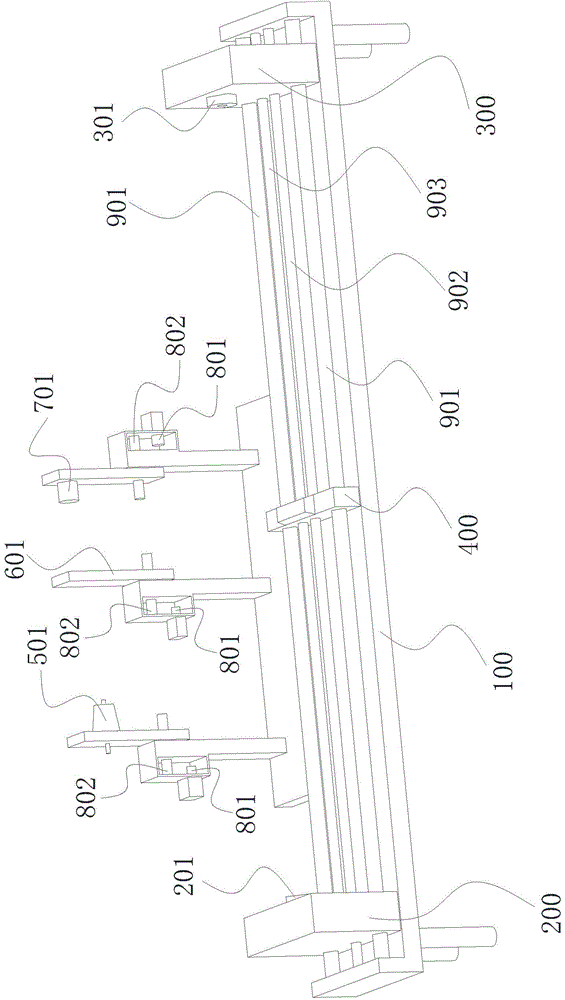

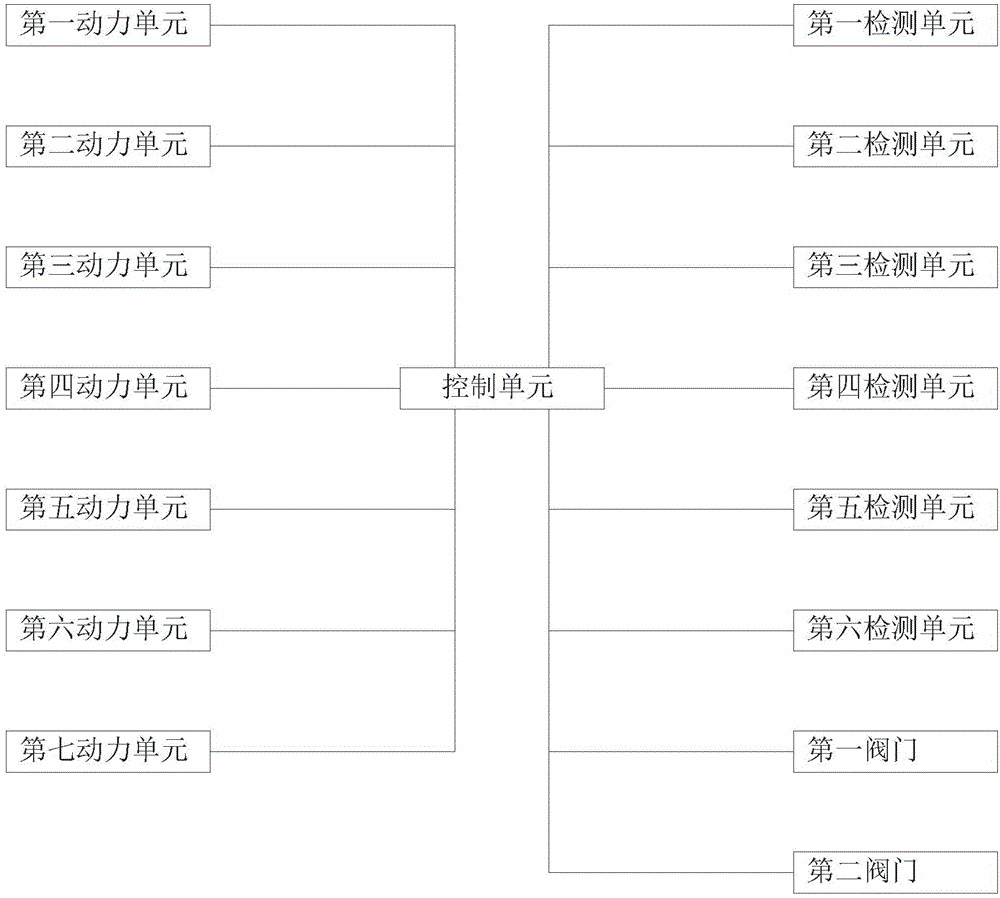

[0031] Such as Figure 1-Figure 4 As shown, the glass automatic processing equipment includes a frame 100, a front-end rotating device 200, a rear seat, a heating device, a pressing plate 601, a thread rolling wheel 701 and a controller, wherein:

[0032] The front-end rotating device 200 is rotatably installed on the frame 100 and its rotation is driven by the first power unit and the first transmission unit connected to it. The front-end rotating device 200 includes a first clamping end of the glass tube from the peripheral side. A clamping mechanism 201, the first clamping mechanism 201 fixes the glass tube on it by fixing one end of the glass tube, and makes the glass tube rotate around its axis under the drive of the first power unit and the first transmission unit;

[0033] The rear seat is slidably mounted on the frame 100 along the direction approaching / away from the front-end rotating device 200 under the drive of the third power unit and the third transmission unit c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com