Washing machine

A technology for washing machines and clothes, applied in the field of washing machines, which can solve the problems of difficult cleaning of grease, excessive use of detergent, and easy deformation of clothes, and achieve the effect of simple and compact structure, less use, and clean clothes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

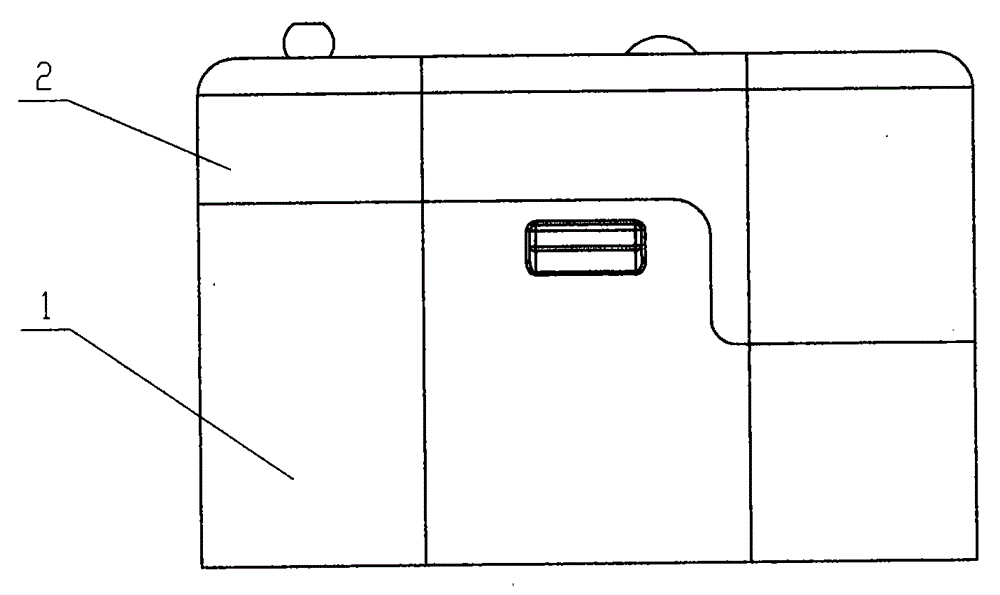

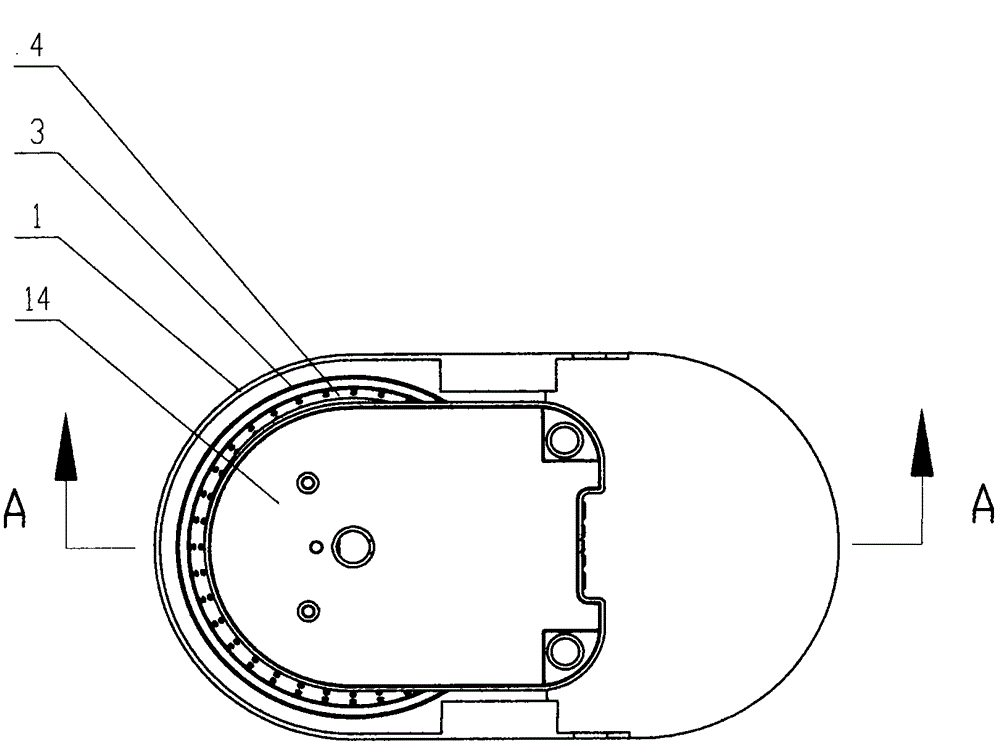

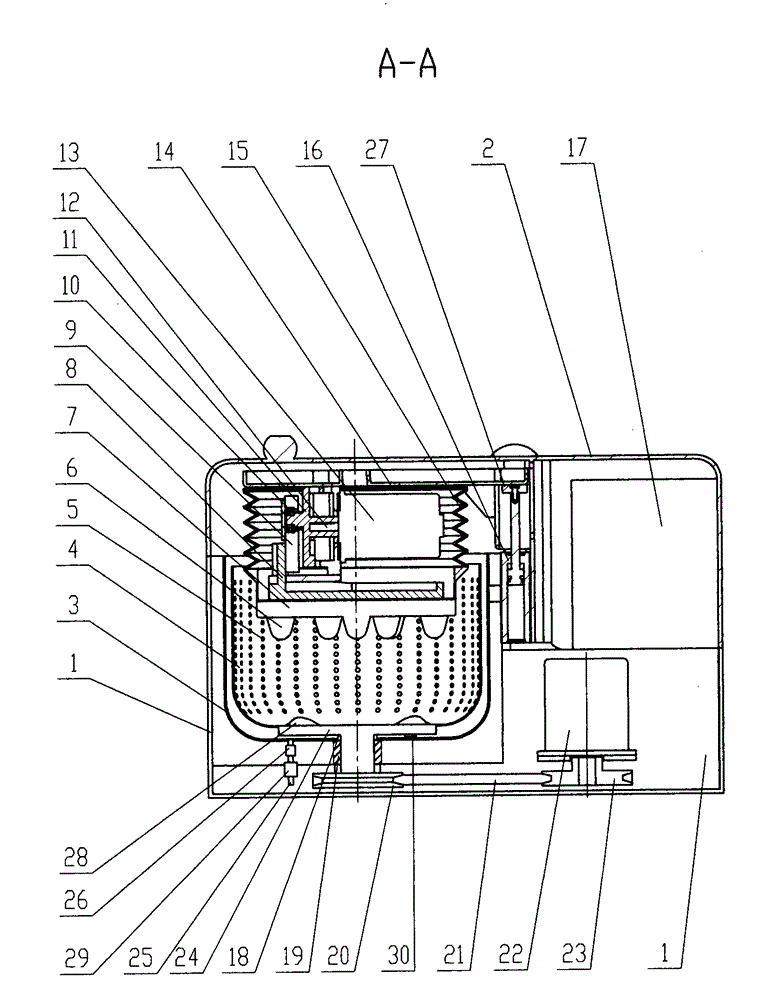

[0030] Specific implementation mode one: as Figure 1~3 As shown, a washing machine includes a casing 1, an upper cover 2, an outer tank 3, an inner tank 4, a washboard 7, a connecting piece 8, a slider 9, a bearing A10, an eccentric wheel 11, a motor shaft A12, a motor A13, and a moving block 14 , folding protective cover 15, cylinder 16, sealing ring 18, bearing B19, pulley A20, belt 21, motor B22, pulley B23, rotating shaft 24, drain port 25, electromagnetic valve 26, it is characterized in that: upper cover 2 Located on the upper part of the outer shell 1, the outer tank 3 and the motor B22 are fixed on the inner side of the outer shell 1, the outer tank 3 does not rotate, the inner tank 4 is concentrically set inside the outer tank 3, the rotating shaft 24 and the inner tank 4 are fixed together concentrically, sealed The ring 18, the bearing B19 and the pulley A20 are installed on the rotating shaft 24 in sequence, and more than two peak-shaped pulsators 28 are arranged ...

specific Embodiment approach 2

[0045] Specific embodiment two: as shown in 1-3, the cylinder 16 of the washing machine can be replaced by an electromagnetic high frequency vibrator or an electromagnetic frequency conversion vibrator, and the electromagnetic high frequency vibrator or electromagnetic frequency conversion vibrator can be generated by electromagnetic high frequency or electromagnetic frequency conversion The vibration drives the protrusion 6 to move up and down, and has the functions of turning, extruding, knocking, rubbing and rinsing the clothes. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com