Bearing bush

A technology for bearing pads and cylindrical shafts, applied in the field of bearing pads, can solve problems such as cumbersome oiling process, inability to store lubricating oil, inconvenient operation, etc., and achieve the effects of improving service life, preventing napping, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0011] The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

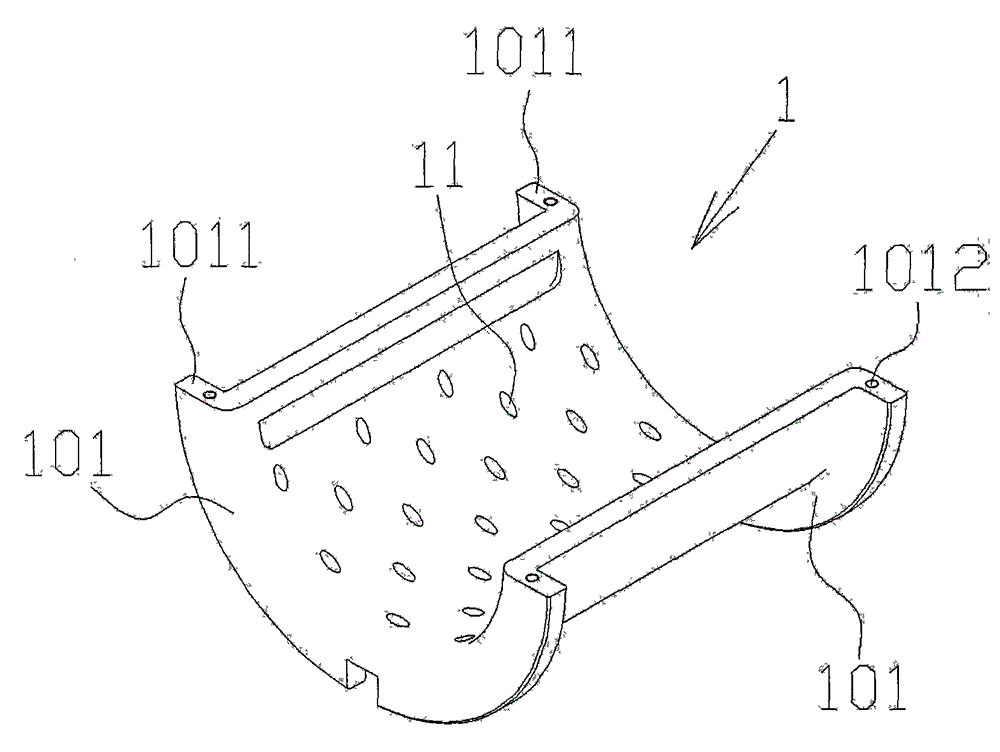

[0012] figure 1 A bearing shell according to an embodiment of the invention is schematically shown.

[0013] Such as figure 1 As shown, the bearing pad provided by the present invention includes a semi-cylindrical bearing pad body 1 .

[0014] Wherein, the length of the bearing body 1 is 298mm-312mm, the inner diameter is 220mm-235mm, and the wall thickness is 16mm-20mm. In this embodiment of the present invention, the length of the bearing body 1 is 300mm, the inner diameter is 220mm, and the wall thickness is 19mm.

[0015] As shown in the figure, the two ends of the bearing body 1 are provided with limiting flanges 101. The thickness of the lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com