Non-linear hourglass type auxiliary spring

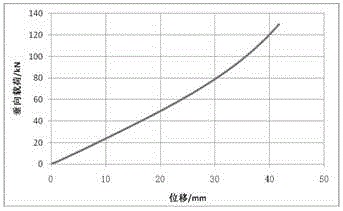

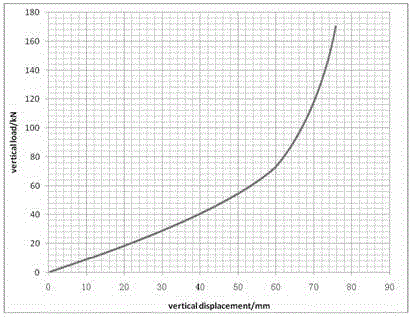

An auxiliary spring, non-linear technology, used in springs, springs/shock absorbers, mechanical equipment, etc. made of plastic materials, can solve problems such as high stiffness, achieve low cost, and solve the deflection difference between heavy load and no-load. Large, increase the effect of compression nonlinearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

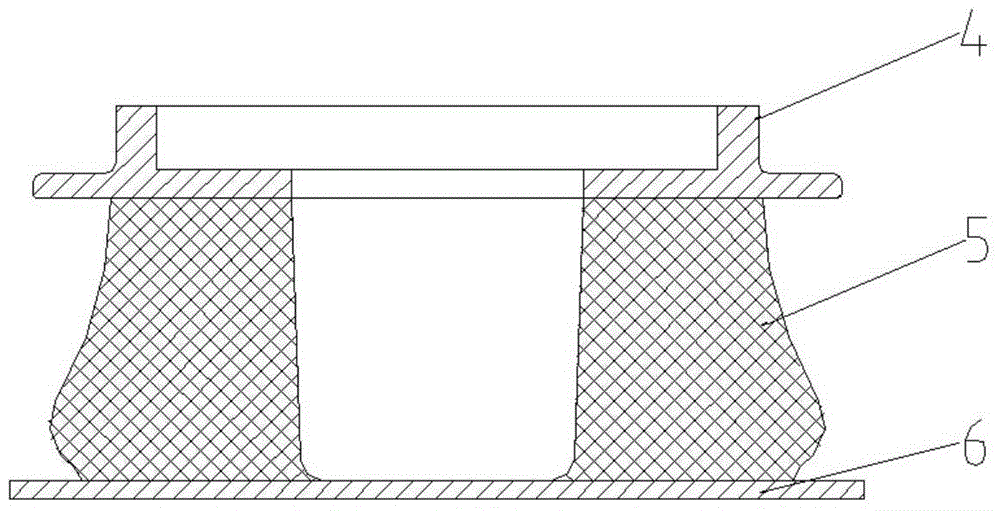

[0016] The non-linear hourglass auxiliary spring of this embodiment comprises a support 1, a rubber 2 and a bottom plate 3, the support 1 is an inverted convex structure, the bottom surface of the support 1 is provided with a downward support column 7, and the support 1 The bottom surface is an inner concave surface; the center of the rubber 2 is provided with a concave hole matching the support column 7, and the rubber 2 wraps the entire support column 7 through the concave hole, and the edge of the rubber 2 is an inclined ellipsoid structure, and the top of the rubber 2 is in contact with the support column 7. The inner concave surface of seat 1 is in contact.

Embodiment 2

[0018] The non-linear hourglass auxiliary spring of the present embodiment is the same as embodiment 1 except the following differences:

[0019] The edge of the inner concave surface of the support 1 is arc-shaped, and when the heavy load is compressed, the rubber 2 and the support 1 change from line contact to surface contact, and the arc-shaped edge of the support 1 can completely fit the rubber 2; the support 1 and the rubber 2 is vulcanized into a whole through the support column 7 and the concave hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com