Performance test equipment for ABS solenoid valve

A technology of ABS solenoid valve and testing equipment, which is applied in the testing of mechanical components, testing of machine/structural components, liquid tightness measurement using liquid/vacuum degree, etc., which can solve waste of manpower, low testing efficiency, and missed inspection of parts and other issues to achieve the effect of high work efficiency and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

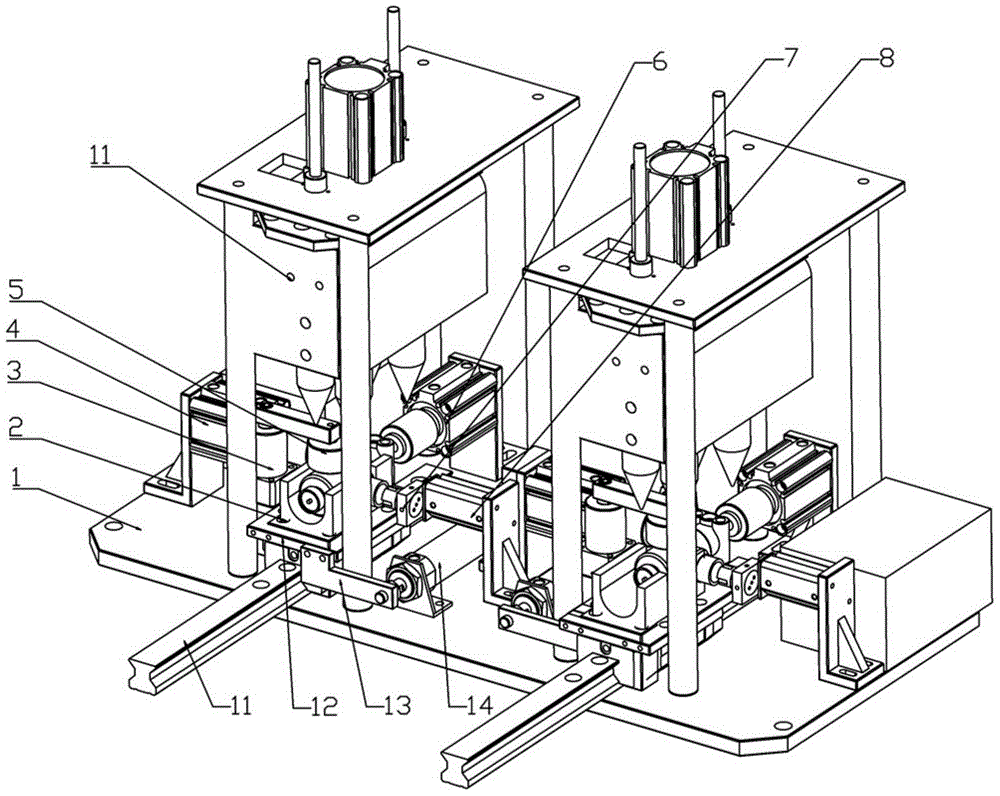

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

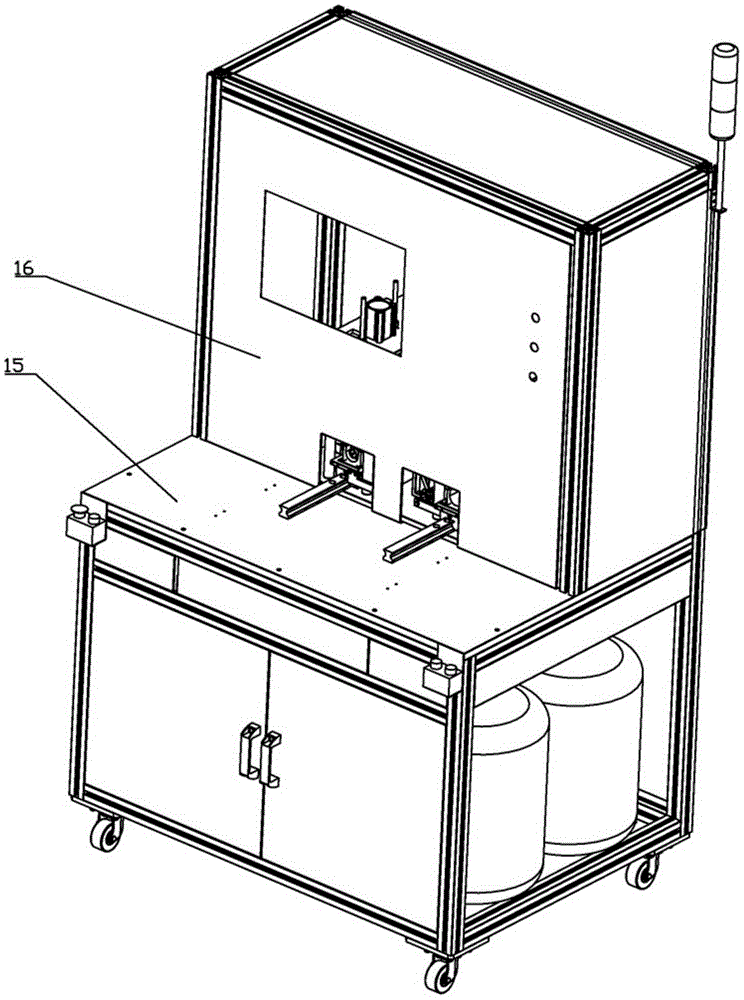

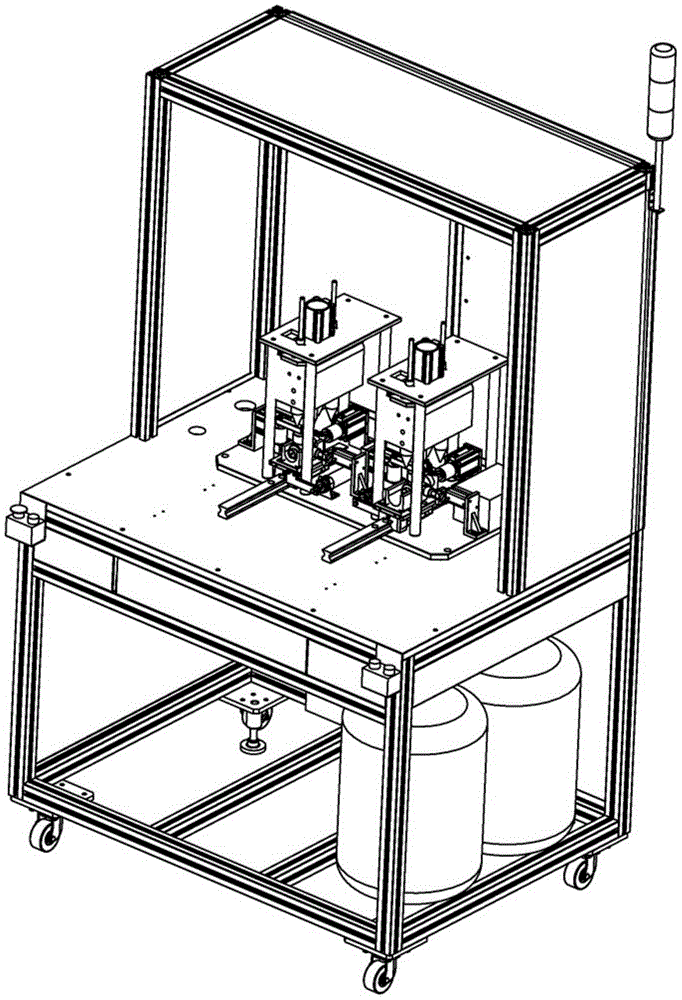

[0034] see Figure 1-3 , an ABS solenoid valve performance testing equipment, has: a performance testing mechanism and a marking mechanism, wherein,

[0035] Such as Figure 4 As shown, the performance testing agency has:

[0036] floor;

[0037] The positioning tool for positioning the solenoid valve arranged on the bottom plate;

[0038] A rotary cylinder fixed on the bottom plate, wherein the rotary arm of the rotary cylinder is provided with a pressing block for pressing the solenoid valve on the positioning tool;

[0039] The plugging cylinder fixed on the bottom plate, the piston rod of the plugging cylinder is fixed with a sealing head capable of blocking the air outlet of the solenoid valve;

[0040] The test cylinder fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com