Method and device for coating binder and monitoring coating quality in magnetic separator

A quality monitoring and adhesive technology, which is applied in the field of magnetizers, can solve problems such as uncoated adhesive or insufficient coated adhesive, failure to ensure uniform coating of adhesive, and permanent magnet falling off. Achieve the effect of improving quality, improving automated assembly efficiency, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

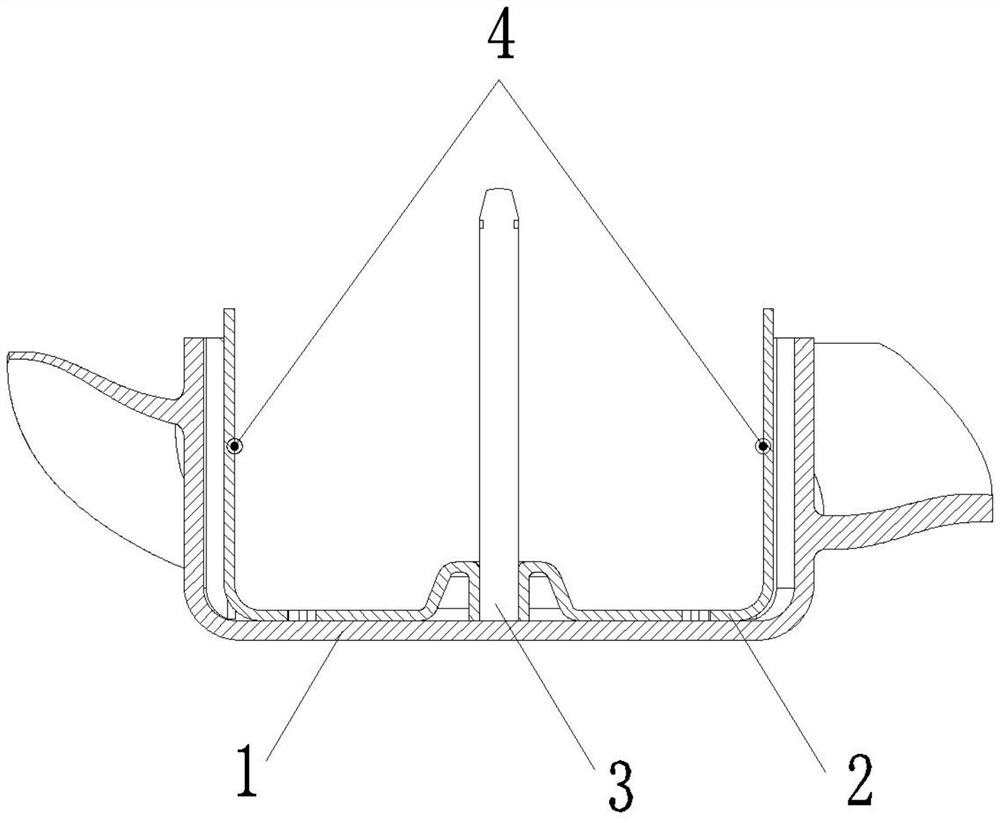

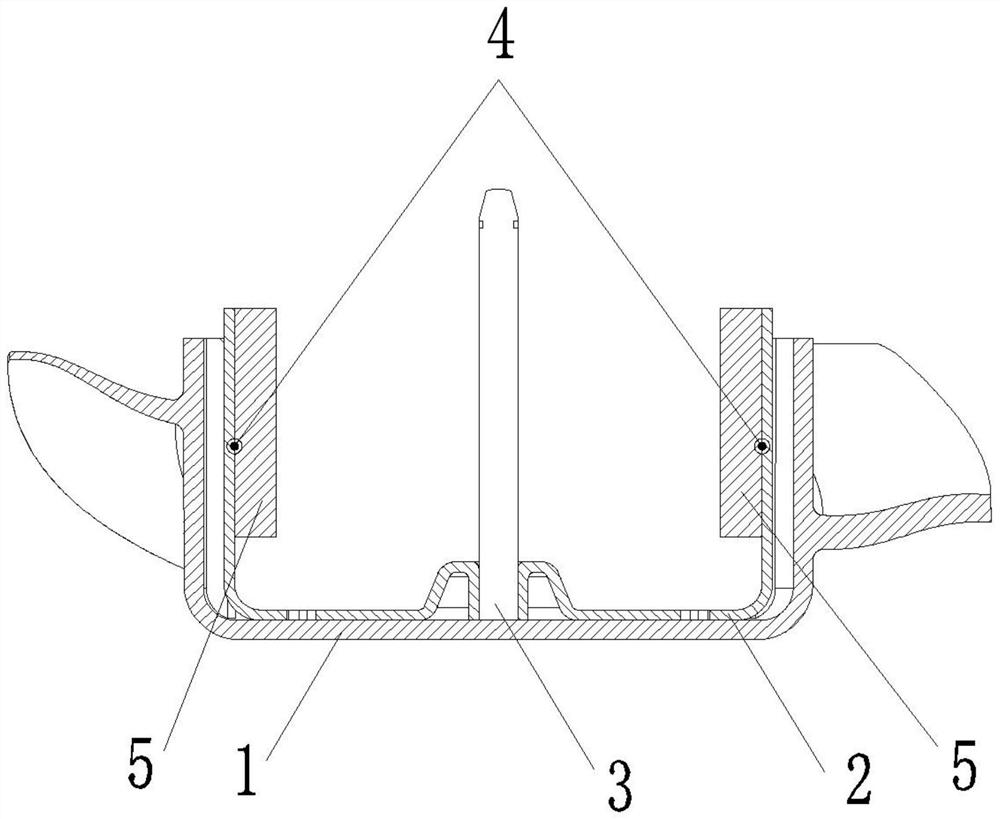

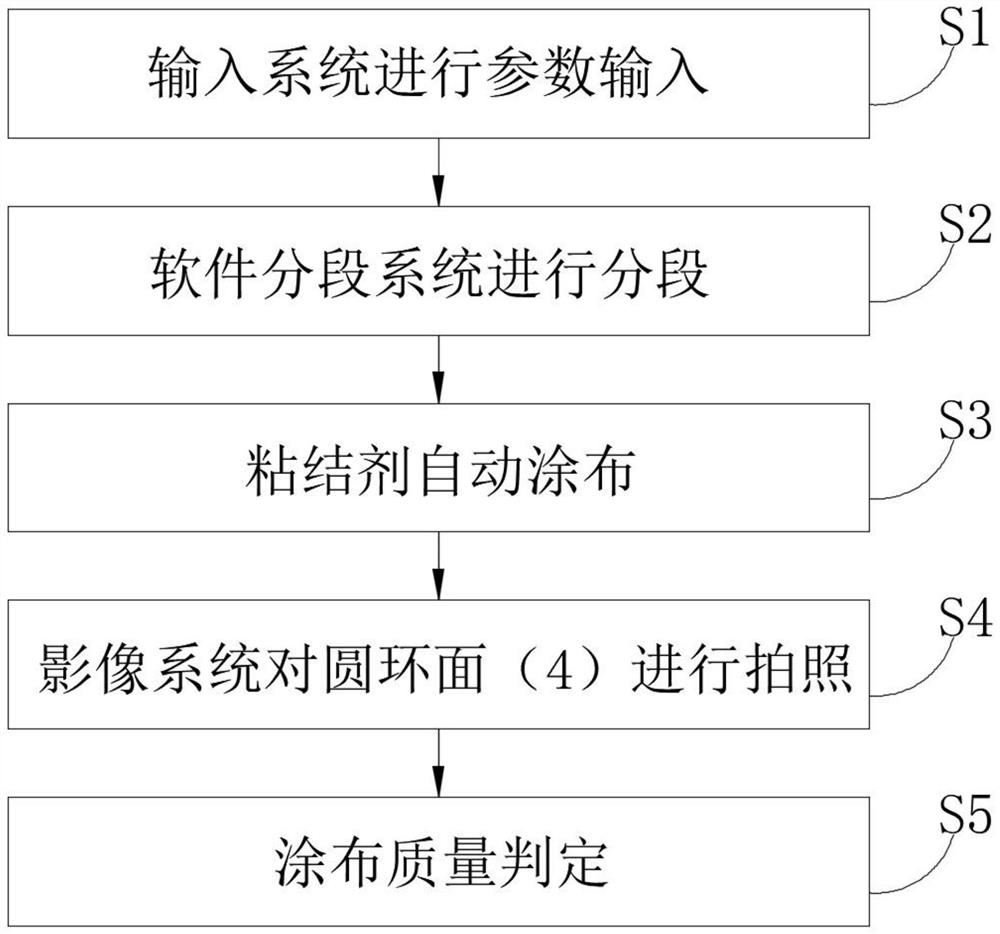

[0044] Please refer to image 3 , Embodiment one of the present invention provides a kind of method for magnetizer coating binder and coating quality monitoring, described method comprises the following steps:

[0045] Step S1: Enter the system for parameter input; in the input system, input the parameters of the torus 4 type, distribution ratio and coating area that need to be coated with adhesive, and input the number of evenly divided torus 4 N, the number of uniform divisions N≥2, in this embodiment, the number N of uniform divisions is an even number, in other embodiments, the number N of uniform divisions can also be an odd number, and at the same time in the data statistics In the process of determining and judging, it is necessary to carry out rounding calculations, there are large errors, and the detection accuracy is low, resulting in poor quality and consistency of adhesive coating.

[0046]If the quality requirements for the adhesive coating are higher, the number...

Embodiment 2

[0059] Please refer to Figure 4 , the second embodiment of the present invention provides a device for coating adhesive and coating quality monitoring of magnetizer, comprising:

[0060] The input system 11 is used to input the parameters of adhesive coating to obtain the parameter instruction of adhesive coating.

[0061] The software segmentation system 12 is connected with the input system 11, and is used to segment the torus 4 that needs to be coated with adhesive, and evenly divide it into N sections.

[0062] Glue dispensing module 13, is connected with described software subsection system 12, is used for adhesive is coated on the toroidal surface 4 evenly along the circumferential direction automatically.

[0063] The imaging system 14 is connected with the dispensing module 13, and is used to take pictures of the torus 4 after the adhesive is applied, to obtain a photo of the torus 4 after the adhesive is applied.

[0064] The storage system 15 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com