Beverage Bottle Compression Mechanism

A compression mechanism and beverage bottle technology, applied to presses, manufacturing tools, etc., can solve the problems of compression devices not working, prone to missing inspections, and misjudgment of compression devices, etc., to achieve accurate counting, ensure compression effects, and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

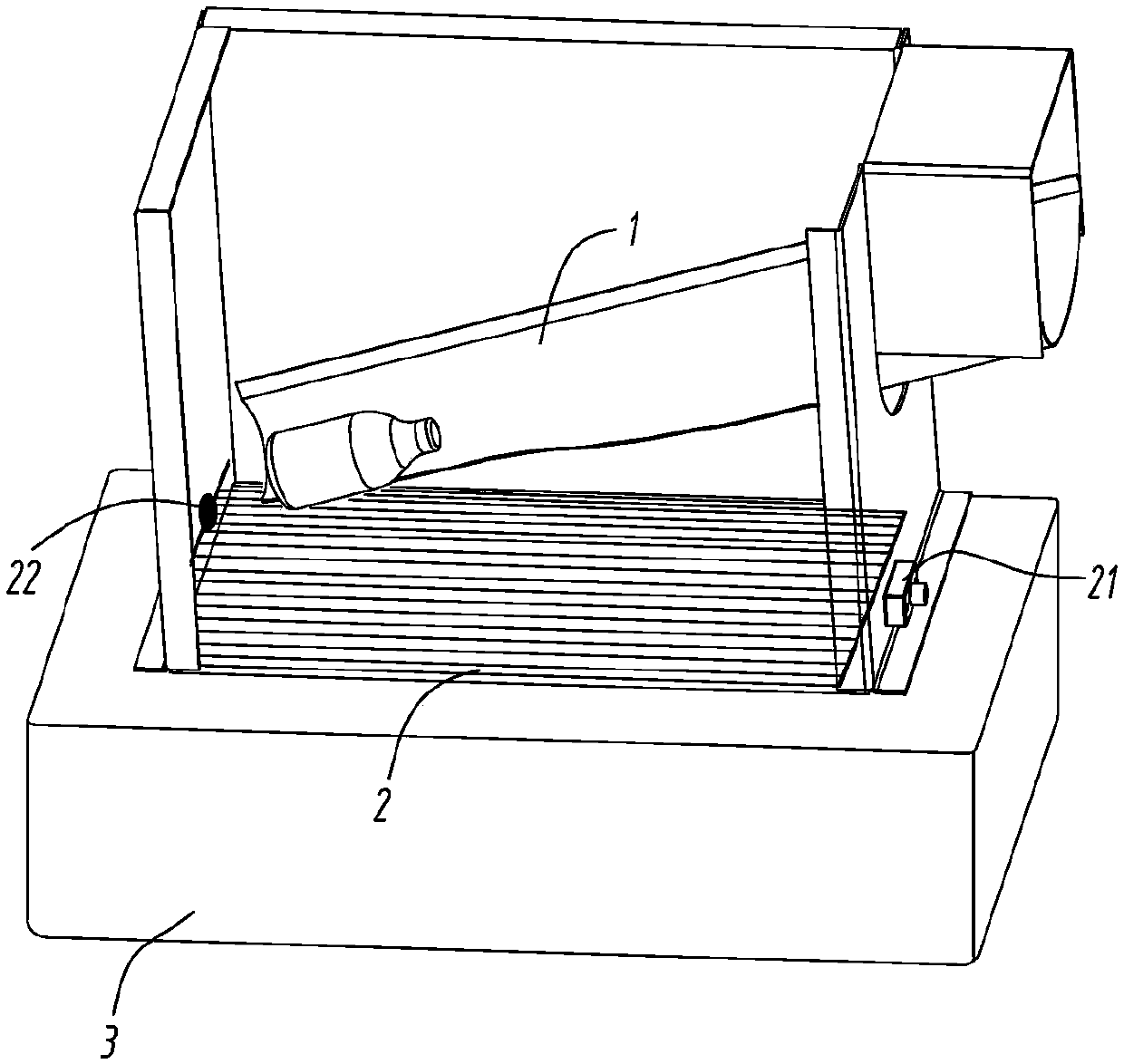

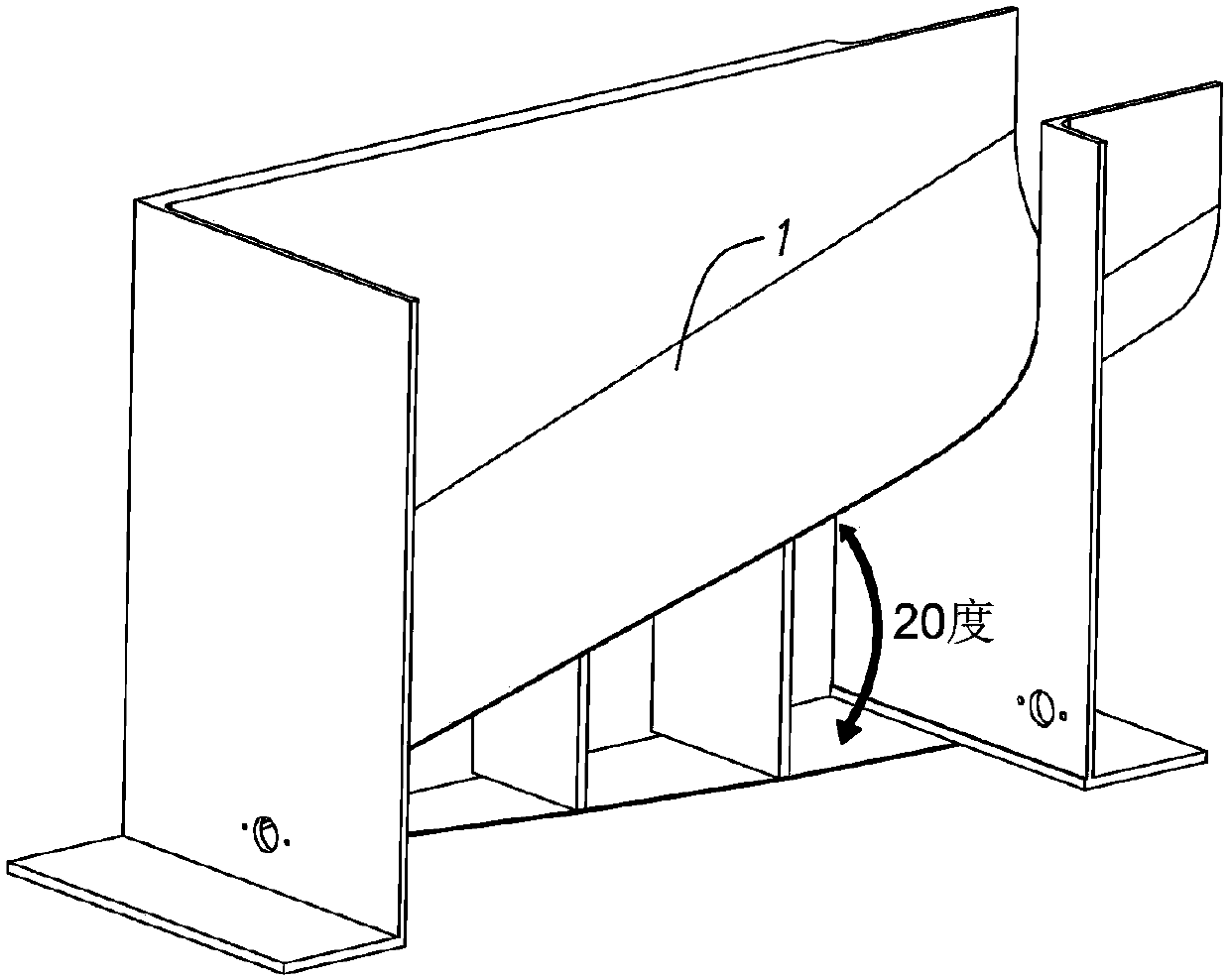

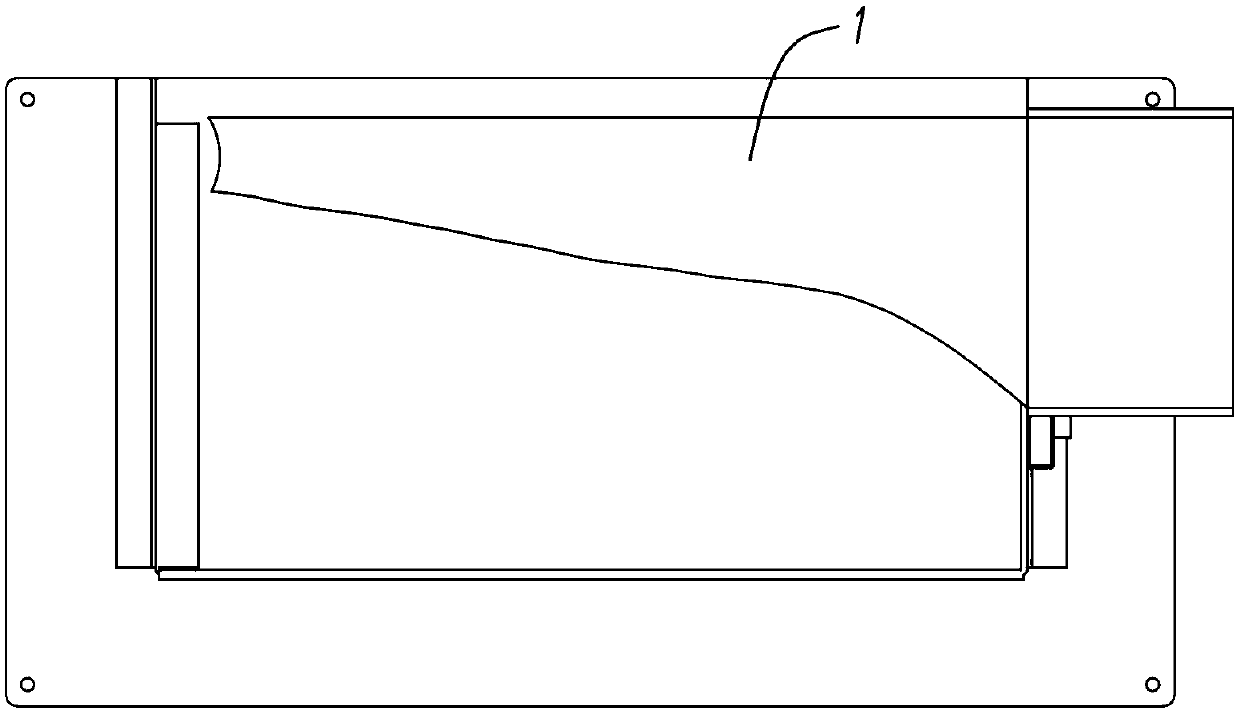

[0017] refer to Figure 1 to Figure 6 A beverage bottle compression mechanism shown includes a blanking chute 1, a blanking detection device 2, a compression device 3, a discharge detection device 4 and a single-chip microcomputer control module; the top surface of the compression device 3 is an unshielded drop Material surface, the bottom surface of the compression device 3 is provided with a discharge port; the blanking chute 1 is located directly above the blanking surface of the compression device 3, and the blanking chute 1 is inclined downward And the cross section is arc-shaped, and the inclination angle of the blanking chute 1 is 20 to 30°; the blanking side of the blanking chute 1 is a beveled surface, and the arc length of the cross section of the beveled surface is determined by The starting end of the blanking chute 1 gradually narrows toward the end; the blanking detection device 2 is arranged on two opposite sides of the blanking surface, including a first linear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com