Construction lift falling prevention safety device field detection device based on sensor technology

A technology for anti-fall safety device and construction elevator, which is applied in the direction of measuring device, testing of machine/structural components, testing of mechanical components, etc. Execution, scientific judgment, and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

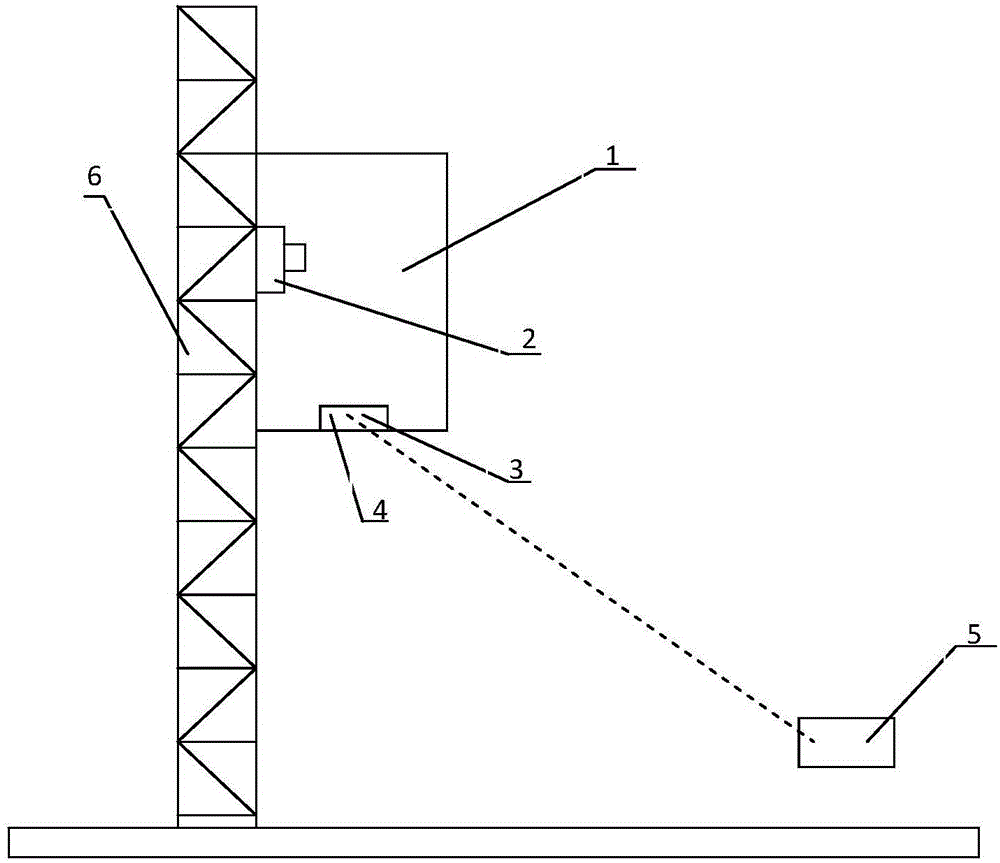

[0019] This embodiment is an on-site detection device for a construction elevator anti-fall safety device, such as figure 1 As shown, it includes a sensor 4 , a data acquisition module 3 and an analysis module 5 . The sensor is a three-axis digital accelerometer, connected to the data acquisition module 3 by wires, and fixed on the data acquisition module by welding technology; The bottom of the hanging cage), the hanging cage slides up and down along the track of the elevator derrick 6.

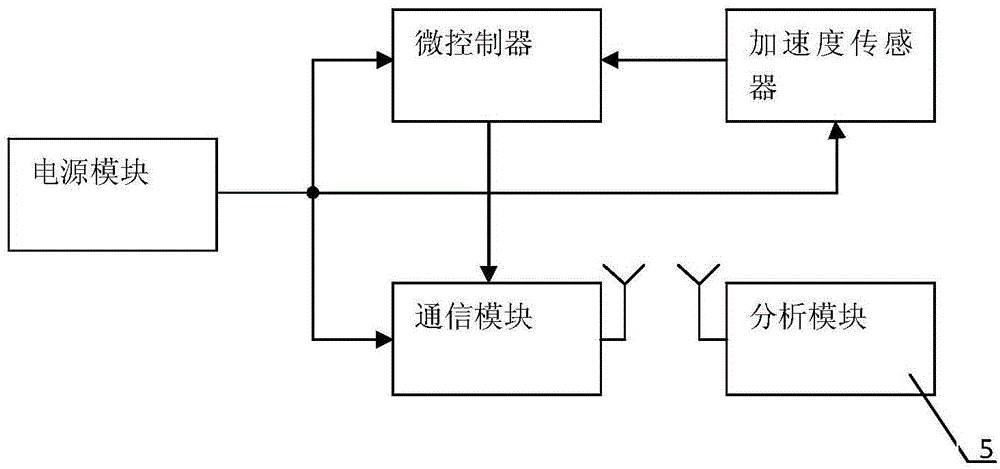

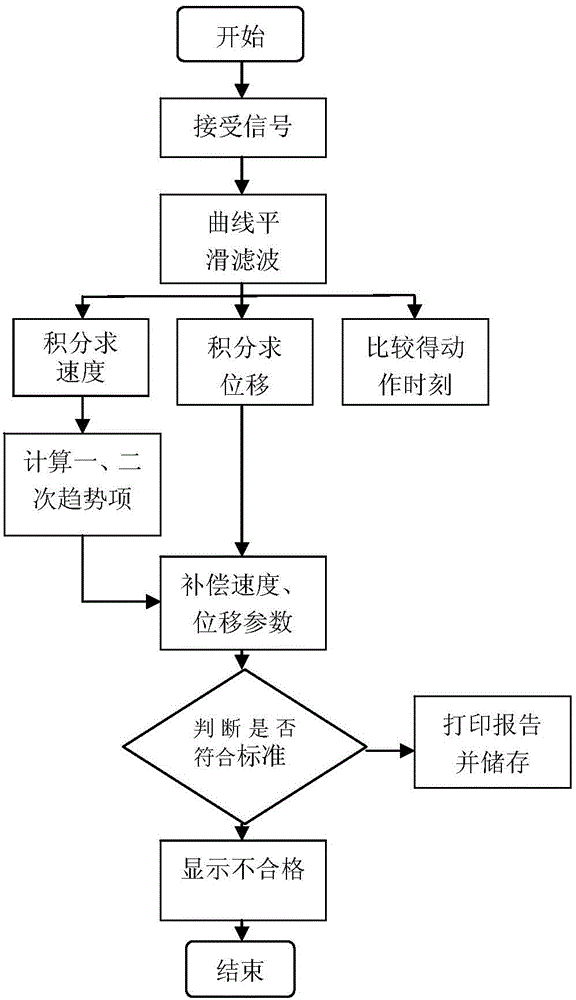

[0020] Such as figure 2 As shown, the data acquisition module 3 includes a microcontroller, a power supply module and a communication interface module. Because the sensor is a digital signal output, the sensor is directly connected to the microcontroller on the data acquisition mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com