Device and method for calibrating contact resistance tester

A technology of contact resistance and calibration devices, which is applied in the direction of measuring devices, instruments, measuring electrical variables, etc., can solve the problems of unable to calibrate the displayed value and cannot guarantee the calibration accuracy of the tester, and achieve the effect of improving the calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

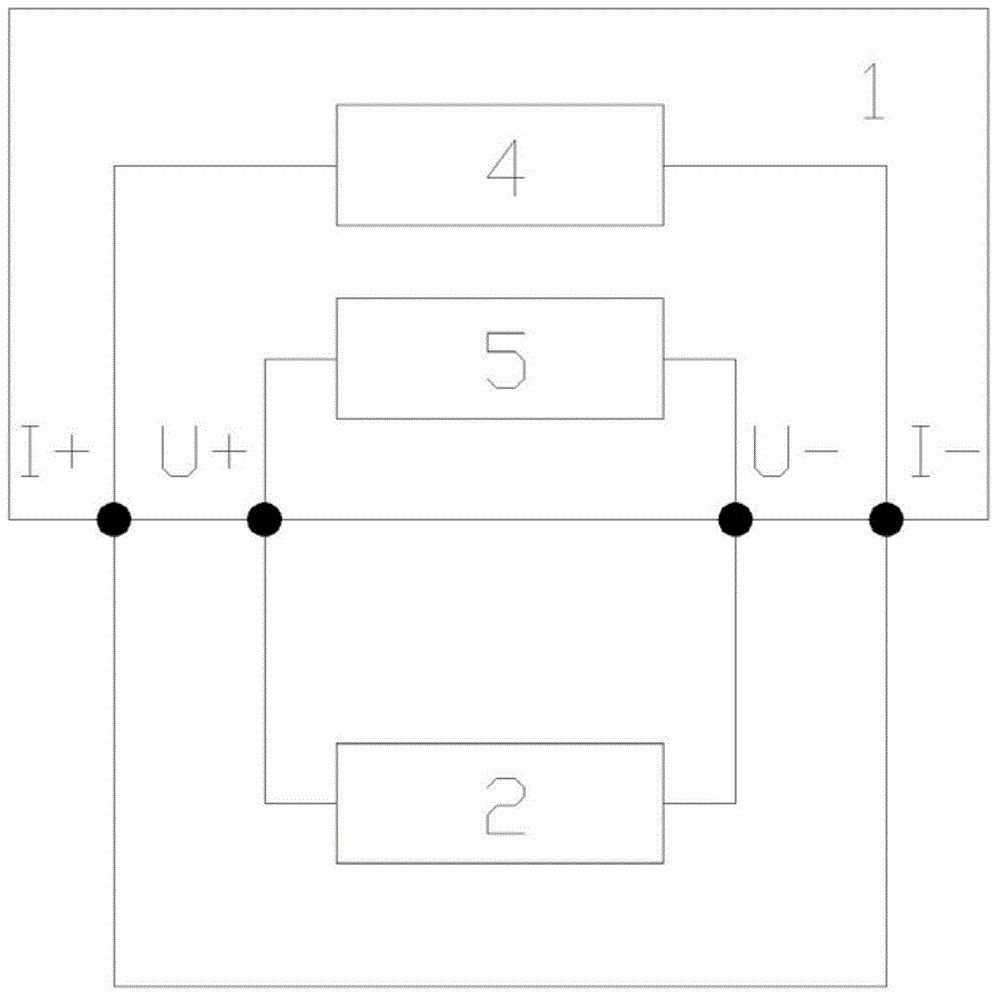

[0033] Such as figure 1 As shown, a contact resistance tester calibration device includes a contact resistance tester 1 under test, and a constant current source 4 and a voltmeter 5 are arranged inside the contact resistance tester 1 under test.

[0034] The output terminal of the constant current source 4 of the tested contact resistance tester 1 is connected to the positive pole and the negative pole, the voltage input terminal of the tested contact resistance tester 1 is connected to a standard voltage source 2, and the standard voltage source 2 is connected to the tested contact resistance tester 1 5 connections within the voltmeter.

[0035] Divide the voltage value of the standard voltage source 2 and the set value of the constant current source 4 according to Ohm's law to obtain the standard resistance value; the voltage detected by the internal voltmeter 5 of the contact resistance tester 1 and the setting of the constant current source 4 Value, divided according to O...

Embodiment 2

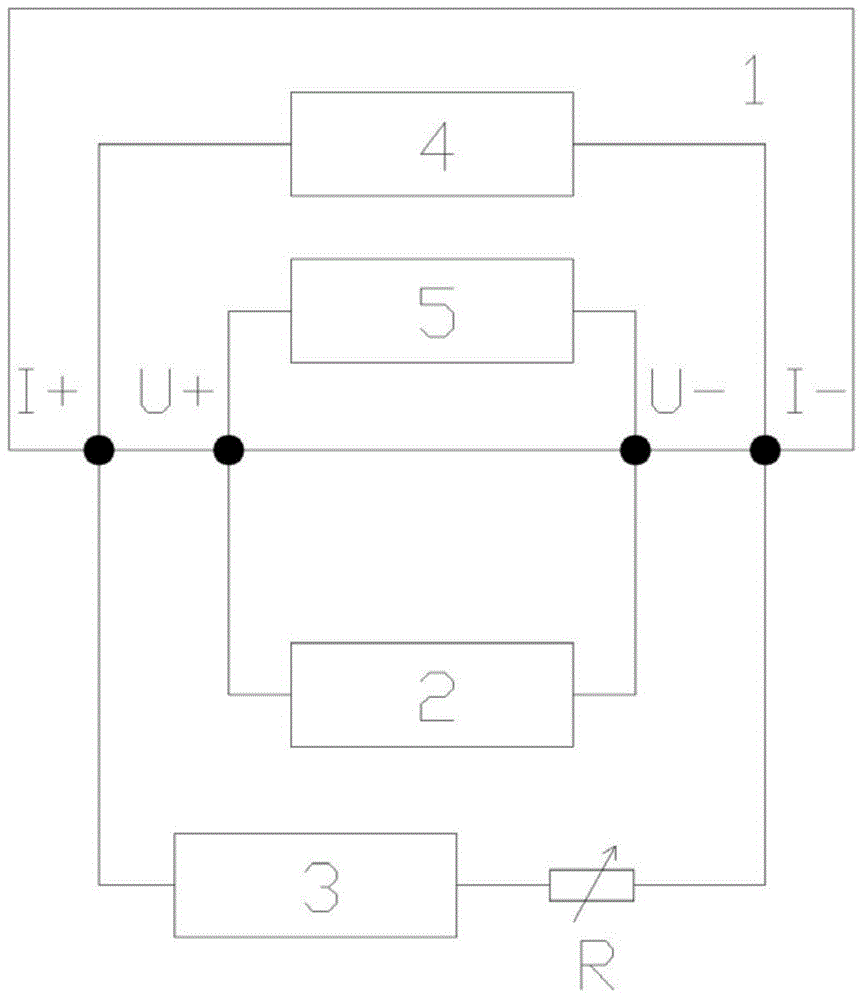

[0042] Compared with the first embodiment, this embodiment further eliminates the possibility of error caused by the constant current source 4 .

[0043] Such as figure 2 As shown, a contact resistance tester calibration device includes a contact resistance tester 1 under test, and a constant current source 4 and a voltmeter 5 are arranged inside the contact resistance tester 1 under test.

[0044] The output terminal of the constant current source 4 of the tested contact resistance tester 1 is connected to an ammeter 3, the voltage input terminal of the tested contact resistance tester 1 is connected to a standard voltage source 2, and the standard voltage source 2 is connected to the tested contact resistance tester 1. The voltmeter 5 is connected.

[0045] In order to protect the ammeter 3 from being damaged, a protective resistor is connected in series between the output terminal of the constant current source 4 of the contact resistance tester 1 and the ammeter 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com