Method for producing a three-dimensional circuit configuration and circuit configuration

A circuit device, three-dimensional technology, applied in the field of manufacturing three-dimensional circuit devices, injection molding circuit devices, can solve problems such as expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

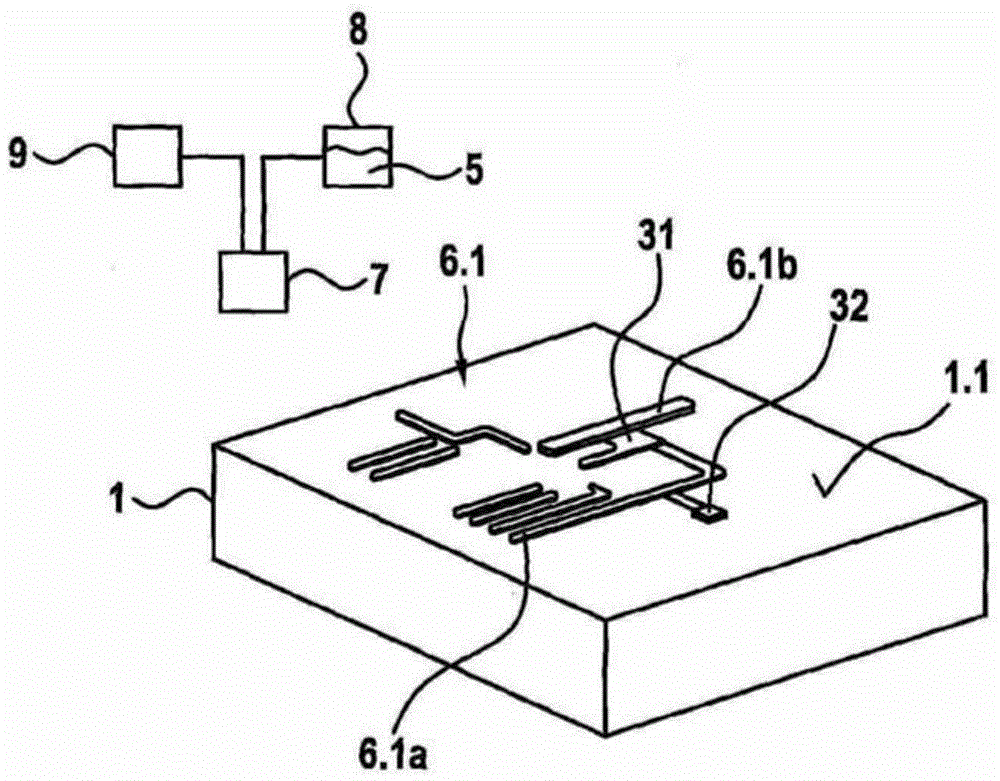

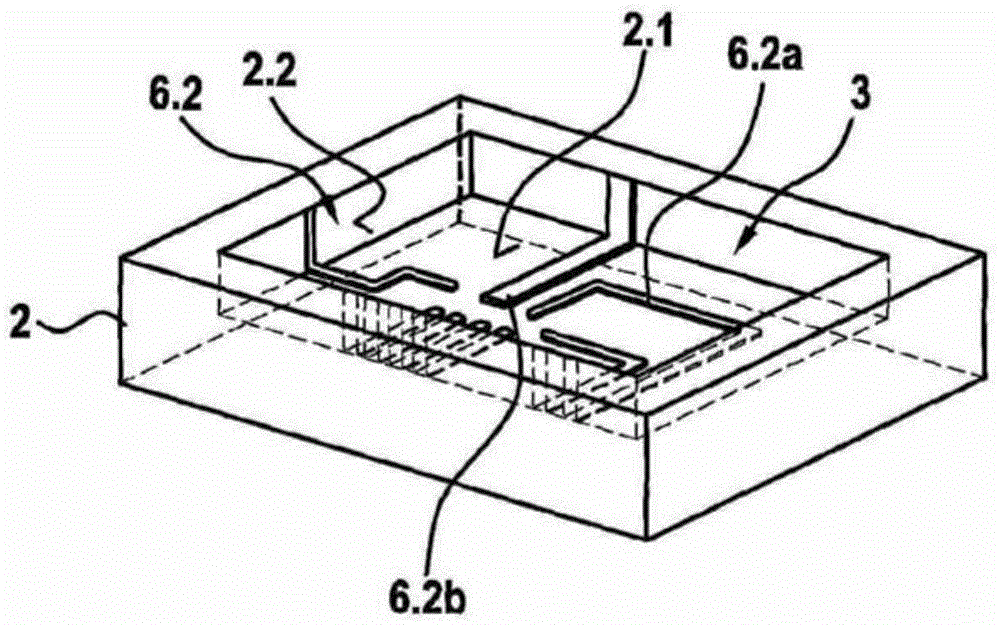

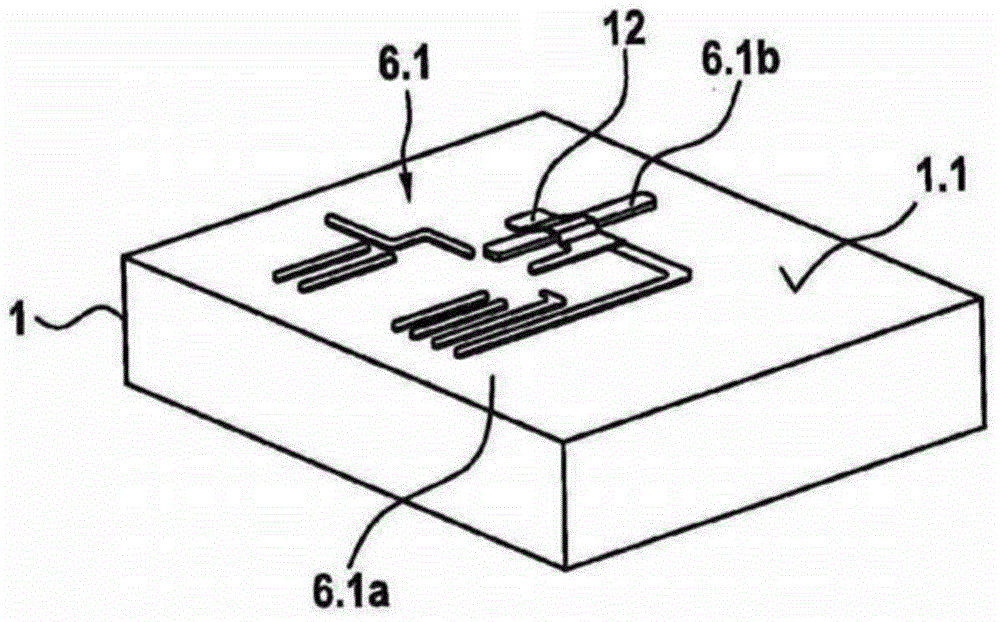

[0027] Figure 1a and 1b Two injection molding tools 1 , 2 are shown, wherein the first injection molding tool 1 is embodied as a cuboid and the second injection molding tool 2 is embodied as a cuboid with a recess 3 . The edge lengths of the base surfaces of the two injection molding tools 1 , 2 are approximately the same, so that the two injection molding tools 1 , 2 can be placed flush with each other. The surfaces 1.1, 2.1 and sides 2.2 of the injection molding tools 1, 2, which are embodied as active surfaces, define the shape of the injection molded circuit arrangement 4 to be produced, that is to say they form the "cathode" of the injection molded circuit arrangement 4, which molding circuit device 4 in Figure 4 and 5 Two examples are shown in . The two shown injection molding tools 1 , 2 here represent only simple embodiments; however, it is also possible to use more than two injection molding tools, for example with a plurality of steps and recesses, in order to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com