A measurement state monitoring method and device for a Coriolis mass flowmeter

A mass flow meter and Coriolis technology, applied in the direction of measuring devices, measuring flow/mass flow, testing/calibrating devices, etc., can solve the problems of wasting time and manpower, avoid disassembly costs, save manpower, and major Engineering Significant Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

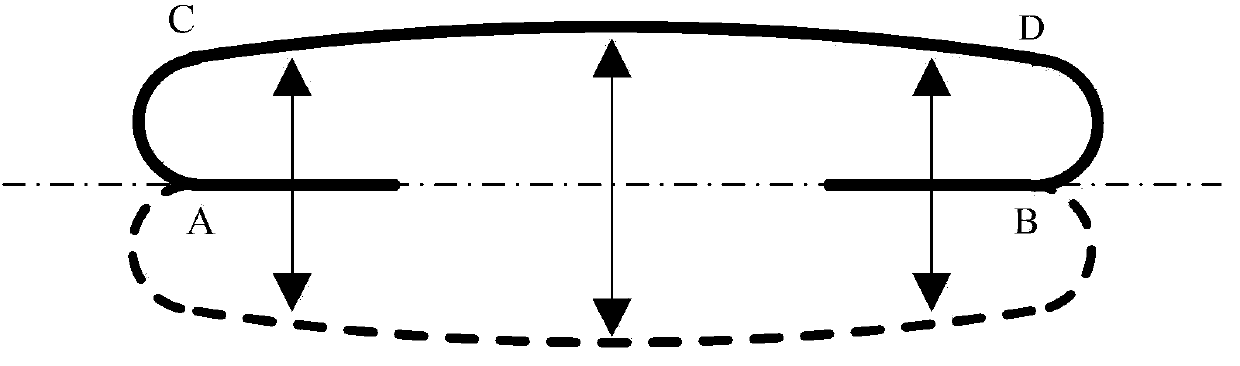

[0034] The basic principle of mass flow meter measurement is the Coriolis effect of a liquid in a vibrating tube. In a typical mass flow meter application, the driving coil 106 of the vibrating tube itself and the driving permanent magnet 206 interact to apply a driving force to the vibrating tube, so that the vibrating tube vibrates at a certain frequency. When no liquid flows through the vibrating tube, all points on the vibrating tube vibrate with the same phase, such as Figure 2a . When a liquid flows through the vibrating tube, the vibrating tube is subjected to the Coriolis force generated by the liquid ( Figure 2b The effect of Fc) in , the Coriolis force makes each point of the vibrating tube produce different phases, such as Figure 2b . The Coriolis force on the AC segment and the BD segment is the same in magnitude and opposite in direction (such as Figure 2b Fc direction shown in). The left detection coil 103 and the right detection coil 205 are placed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com