A special degassing device for a new transformer oil chromatographic on-line monitoring device

A technology of transformer oil and monitoring device, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of high system vacuum requirements, degassing effect sensitivity and stability defects, etc. good gas effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

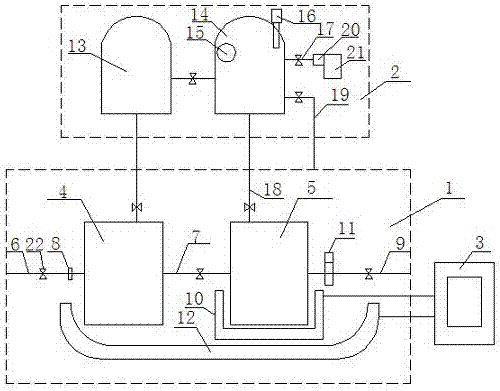

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] A degassing device dedicated to a novel transformer oil chromatographic on-line monitoring device, including a sampling chamber 1, a vacuum degassing chamber 2 and a controller 3, wherein the sampling chamber 1 includes a primary oil storage chamber 4 and a secondary oil storage chamber 5. The primary oil storage chamber 4 is provided with a primary oil inlet pipe 6 and a primary oil outlet pipe 7, and a flow meter 8 is provided at one end of the primary oil inlet pipe 6, and the primary oil outlet pipe 7 is connected with the secondary oil storage chamber. The secondary oil storage chamber 5 is provided with a secondary oil outlet pipe 9, the secondary oil outlet pipe 9 is provided with an oil pressure detector 11, and the secondary oil storage chamber 5 is equipped with an ultrasonic vibration A device 10, the primary oil storage ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com