Lateral fastening device in tooth meshing for tin bath bottom brick

A technology of tin bath bottom bricks and fastening devices, which is applied in the field of tin bath forming equipment, and can solve problems such as threaded fasteners that cannot be fastened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

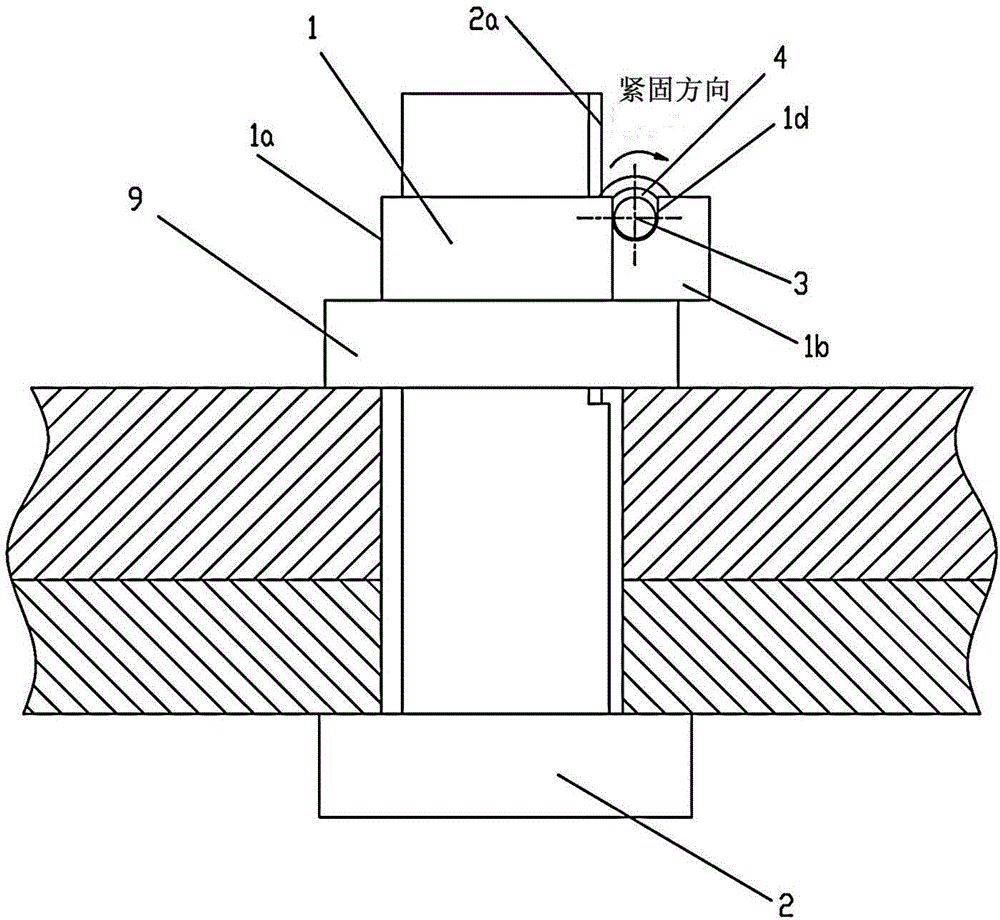

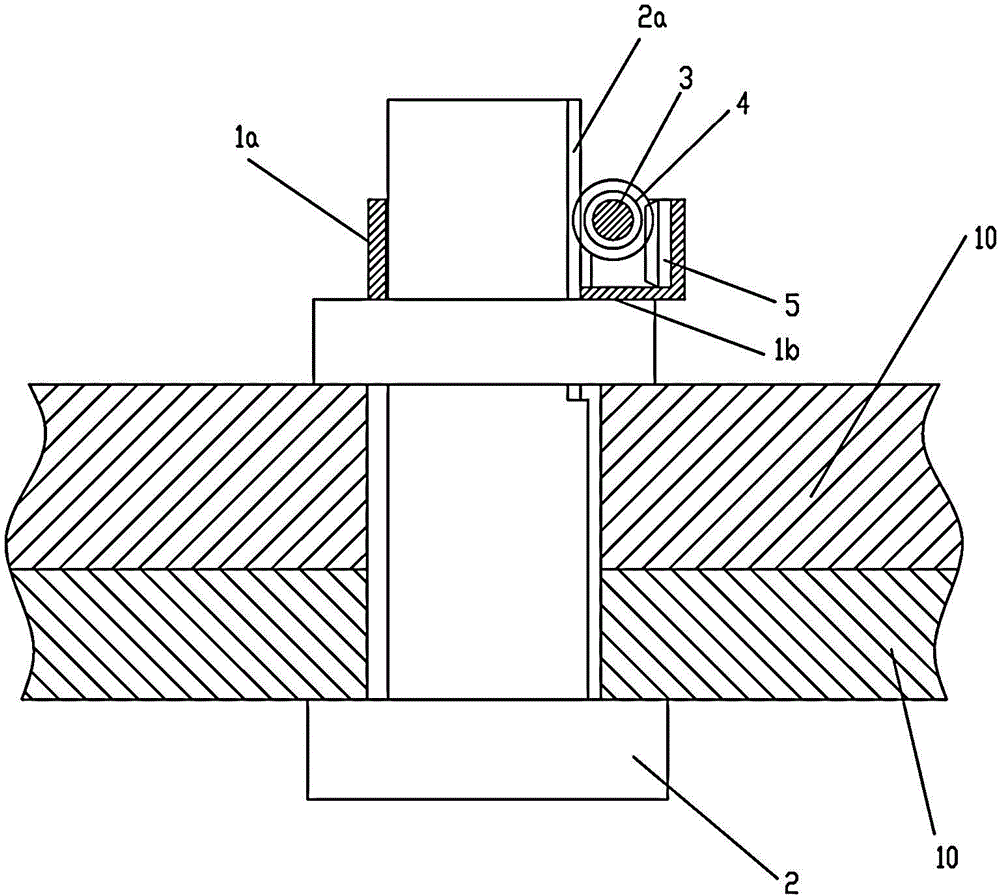

[0022] A toothed tin bath bottom brick side fastening device such as figure 1 As shown, it includes a pair of movable parts 10 to be fastened, and the movable socket fastening rod 2 on the fastened parts 10, the cross section of the fastening rod 2 can be set to square, circular and other shapes that are easy to process and manufacture , choose a circle here, and set a section of rack teeth 2a arranged along the axis on one side of the fastening rod 2 . One end of the fastening rod 2 is sleeved with an annular pressure block 9 that is press-fitted with the end face of the fastener 10 to be fastened, and the end of the fastening rod 2 is sleeved with a compression member 1 that is press-fitted with the other end face of the press block 9 .

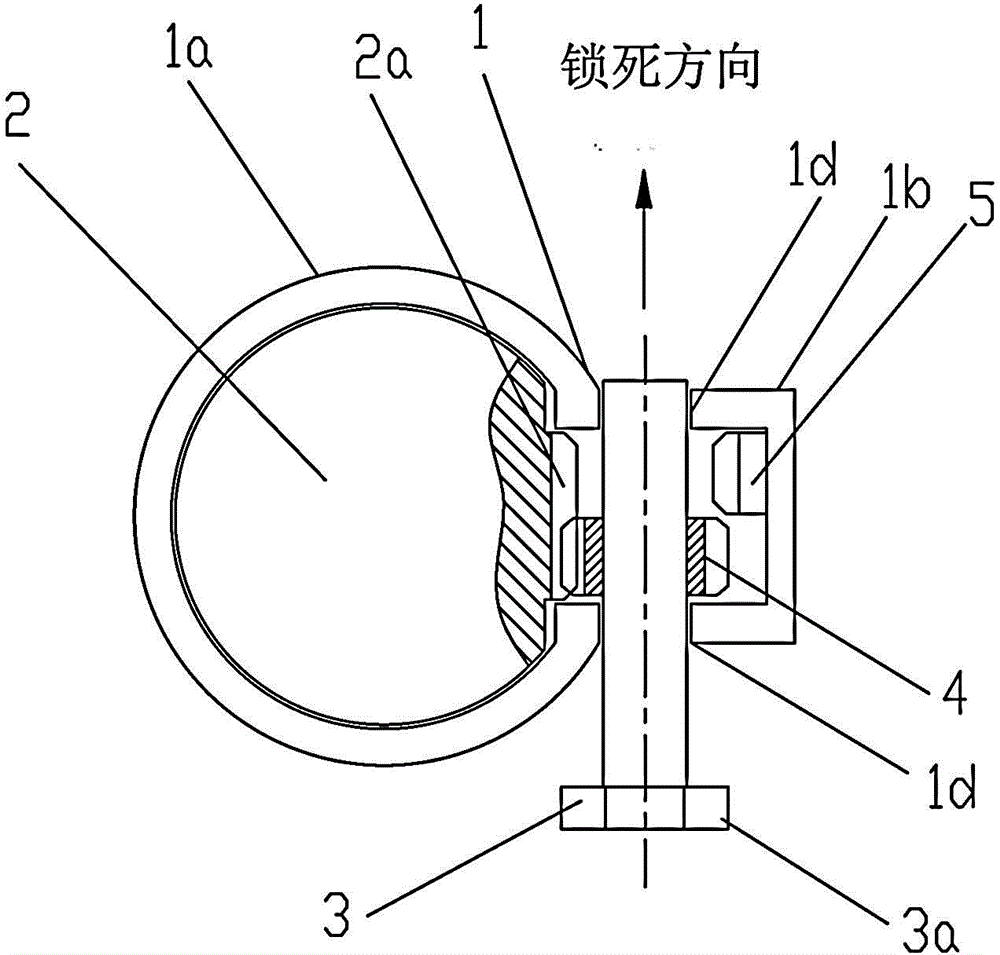

[0023] Such as figure 2 and image 3 , the compression piece 1 is provided with a compression sleeve 1a that slides and fits with the peripheral surface of the tightening rod 2, the compression sleeve 1a is pressed against one end surfac...

Embodiment 2

[0029] A toothed tin bath bottom brick side fastening device such as Figure 5 As shown, the bottom plate 7 of the tin bath is included, and a group of fastening rods 2 are welded on the bottom plate 7 of the tin bath. One side of the fastening rod 2 is provided with rack teeth 2a arranged along the axis. A group of refractory tin bath bottom bricks 6 are laid on the tin bath bottom plate 7, and two fastening holes 6a whose axes are perpendicular to the tin bath bottom plate 7 are arranged on each tin bath bottom brick 6, and the fastening holes 6a are a port and the tin bath bottom brick 6. A blind hole connected to the bottom surface of the bottom brick 6 . The tin bath bottom brick 6 is provided with horizontal side tightening holes 6b respectively connected with the corresponding fastening holes 6a, and the side tightening holes 6b are blind holes with a port communicating with the side of the tin bath bottom brick 6 .

[0030] The corresponding fastening rod 2 is sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com