Grading method of cement-base self-leveling mortar

A self-leveling mortar and cement-based technology, which is applied in the field of cement-based self-leveling mortar, can solve problems such as undefined, fast-setting early-strength fluidity retention, high fluidity of wet mortar, and stable non-segregation properties. The effect of increased wet and dry density, high rigor and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

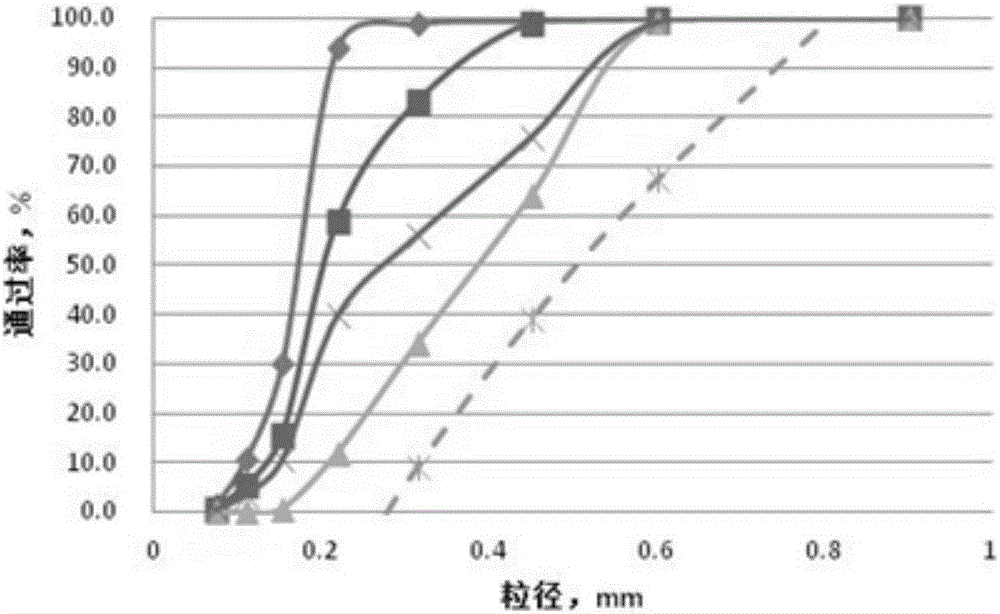

[0090] The first step: sieve and analyze several types of sand required for production. The particle size of the sand is generally controlled between 0.08 and 1mm. Therefore, 8 sieves with different particle sizes are selected in this range, 0.90mm, 0.60mm, 0.45mm, 0.315mm, 0.22mm, 0.154mm, 0.11mm and 0.074mm. The sieves are placed in the order of small to large apertures and bottom to top, and the bottom of the sieve is attached. Pour a sand sample (100-200g) into the uppermost sieve, add a sieve cover, and sieve in sequence.

[0091] Step 2: Use a vibrating sieve machine to sieve for 10 minutes, remove them, and sieve them one by one by hand, or directly by hand, until the throughput per minute does not exceed 0.1% of the total sample.

[0092] Step 3: Weigh the sieve residue of each sieve, the sum of the sieve residue of all sieves and the residue in the bottom of the sieve, compared with the total amount of the sample before sieving, the difference shall not exceed 1%.

[...

Embodiment 2

[0120] Carry out sand gradation according to the step of embodiment 1, difference is: B=50, then as shown in table 9, table 10, table 9 is the data table of three kinds of sand before fitting and after fitting, and table 10 is three kinds of sand Formula comparison data table before and after compounding and fitting;

[0121] Table 9 The proportion data table of three kinds of sand before and after fitting

[0122] Type of sand

before fitting

After fitting

coarse sand

33

14

Middle sand

33

61

fine sand

34

25

total

100

100

[0123] Table 10 The formula comparison data table of ternary sand before and after compounding and fitting

[0124]

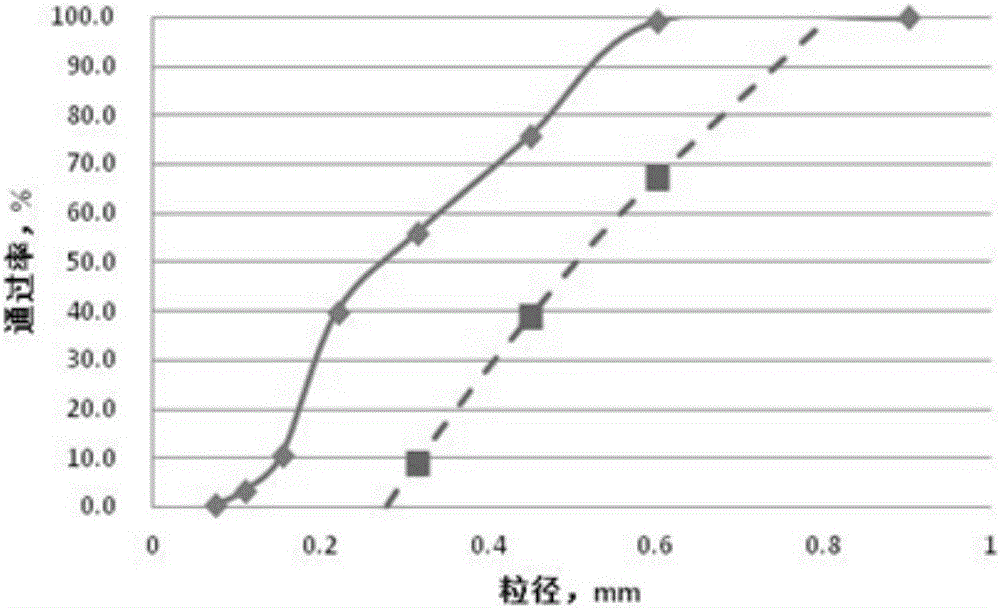

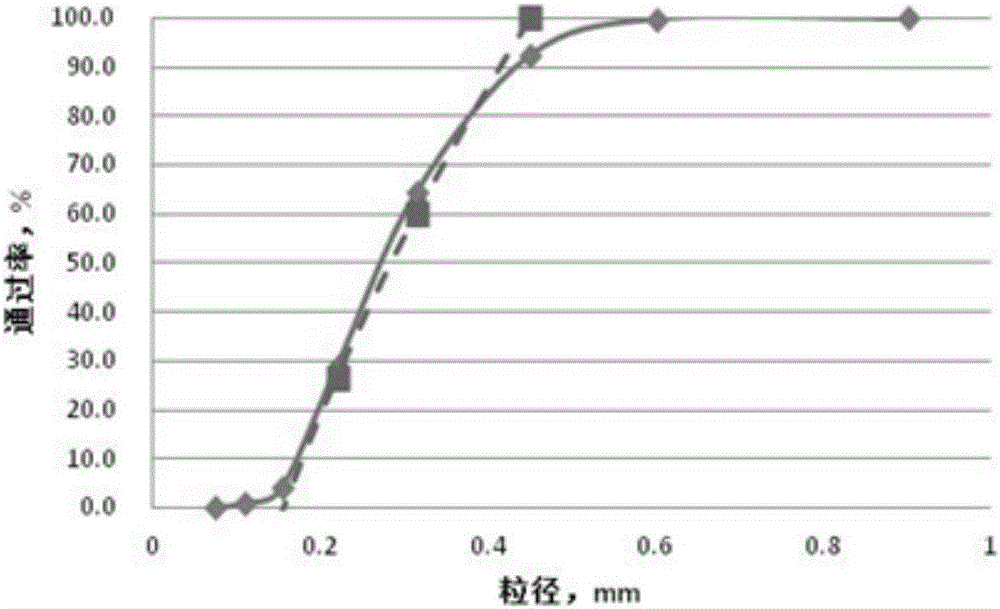

[0125] After adjustment, the final D=0.48, B=50, as shown in the sand gradation table 10; Figure 8 It is the curve diagram of Fuller curve and 6# formula when D is 0.8, Figure 8 The middle ◆ curve represents the gradation curve of 1# sand, and the ▲ cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com